Software Will Eat the Reliability Management World

Key Takeaways

- Software changed business because it allowed more effective ways of providing what people needed with lower capital and infrastructure costs.

- Improving failure prediction has long relied on capital intensive methods but recent advances in technology have shown a path, using software, which breaks this paradigm.

- Falkonry has been applying time series AI to solve reliability issues with widespread success and advantages compared to traditional techniques.

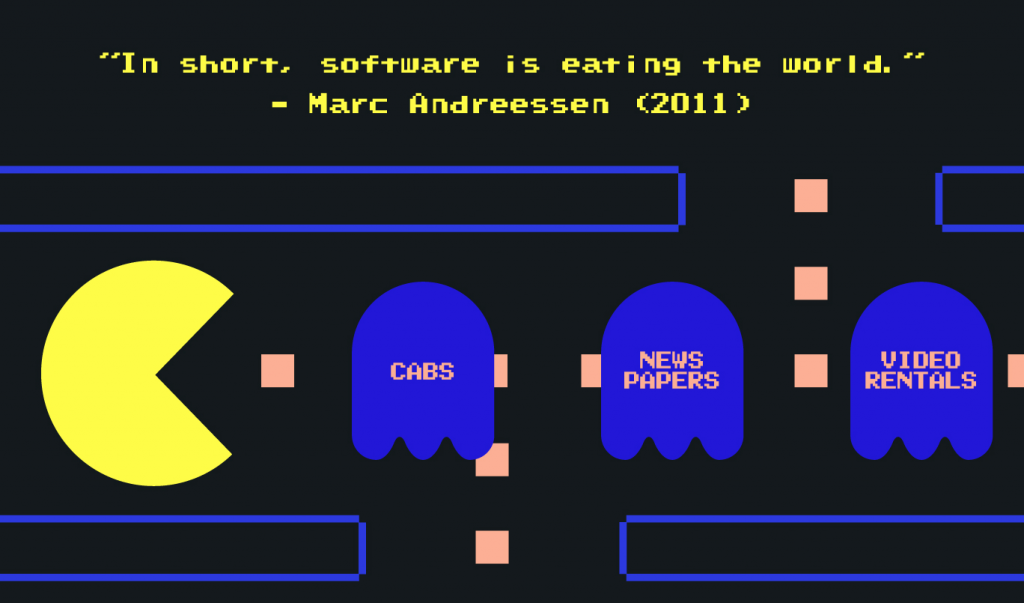

Software is eating the world. In the future every company will be a software company.

– Marc Andreessen

In his 2011 article, Marc outlined the reasons why traditional companies are increasingly using software to drive their business. Primary among them is the factor of 100 reduced cost in the computing resources required to do the things we need, such as delivering content, running the algorithms which provide buyers with a better recommendation or optimizing supply chain decisions to provide better deliveries. Equally important is that these advantages were obtained without large investments in capital equipment, infrastructure or employee training.

Uber was built on a ubiquitous base of GPS enabled smartphones and privately owned cars. Uber’s advantage was a cloud based algorithm and an idea. Nine years after this article was published, we have seen how prescient it was in describing the world.

Now, software is coming to the world of reliability management for the same reasons. Sensor-based failure prediction exploits a known relationship between a symptom and a cause. For example, an ultrasound sensor helps us take advantage of the relationship between the sound a spinning shaft makes and the degree of wear in the bearing that supports it. This approach requires a capital intensive base of integrated and purpose-built sensors. Those ultrasound sensors took time and significant expense to research and develop. They also required a large investment from users to purchase and deploy. Just as digital content delivery decoupled movie rentals from the need to visit a physical store, software has changed the way sensors can be used: Failure prediction has been decoupled from purpose-built sensing hardware, the cost of hardware integration, and the associated operating costs.

The technology for using sensors to detect signals they were not designed to detect exists today. Whether it is listening to music by watching empty chip bags with a high speed camera, eavesdropping on a conversation through a telescope by looking at a lightbulb or exploiting seismometers to understand enemy troop movements, the proof that sensors can be repurposed using software is already here.

Machine learning (ML) is especially suited to the types of detection problems that reliability management applications present. It excels at finding the kinds of symptom – problem relationships which traditionally require multiple, custom, physical sensors and sensor fusion. Because ML can find relationships which are much more subtle or complex than a human can see, it avoids that kind of complexity. What is needed to challenge and displace the traditional sensor-based options are ML approaches which are cost effective in application discovery, deployment and on-going continuous improvement costs.

At Falkonry, we have used the LRS platform to perform feats of sensing alchemy, translating operational data from existing sensors into actionable warnings, enabling improved reliability management. Examples include:

- Predicting LNG compressor seal failures weeks in advance by detecting precursor patterns in compressor pressure, flow rate and temperatures as well as in seal gas pressures and flows. This enabled proactive maintenance avoiding $200,000 to $1,000,000 in downtime and penalties.

- Predicting early pinch roller wear up to a week in advance on steel casting equipment by finding warning patterns within roller speeds, motor torques and currents. This avoided over $1.7M per year in production losses to unplanned downtime.

- Predicting ore quality in a grinding mill by identifying precursor patterns across motor currents, temperatures and reagent valve positions. This allowed operators to be alerted about impending low quality events, saving $900,000 per year in lost productivity due to unplanned shutdowns and clean up.

We believe that the missing piece, a quick-to-deploy system usable by the operational experts you already have, is here: It’s called Clue. We hope you brought your appetite.