Why Predictive Maintenance in Manufacturing is at a Crossroads

Key takeaways:

- Predictive maintenance in manufacturing is impeded by the lack of predictive data and difficulty scaling to the required number of use cases

- Generalized predictive approaches struggle to accommodate the unique characteristics of diverse equipment

- Anomaly detection and Smart operationsoffer a proactive solution, illuminating areas needing attention before defects arise

Predictive maintenance in manufacturing has gained significant traction in the equipment business and among Original Equipment Manufacturers (OEMs). However, despite the buzz, maintenance teams remain skeptical due to its practical limitations. To many manufacturing leaders, pursuing predictive maintenance feels like “chasing one’s own tail,” a sentiment we’re increasingly hearing echoed by those in charge of plant maintenance. The disappointment arises from the lack of predictive data in the form of precise and complete maintenance and downtime records. As a result, substantial time and effort from the operations team is required to reap the benefits of predictive maintenance under conventional approaches.

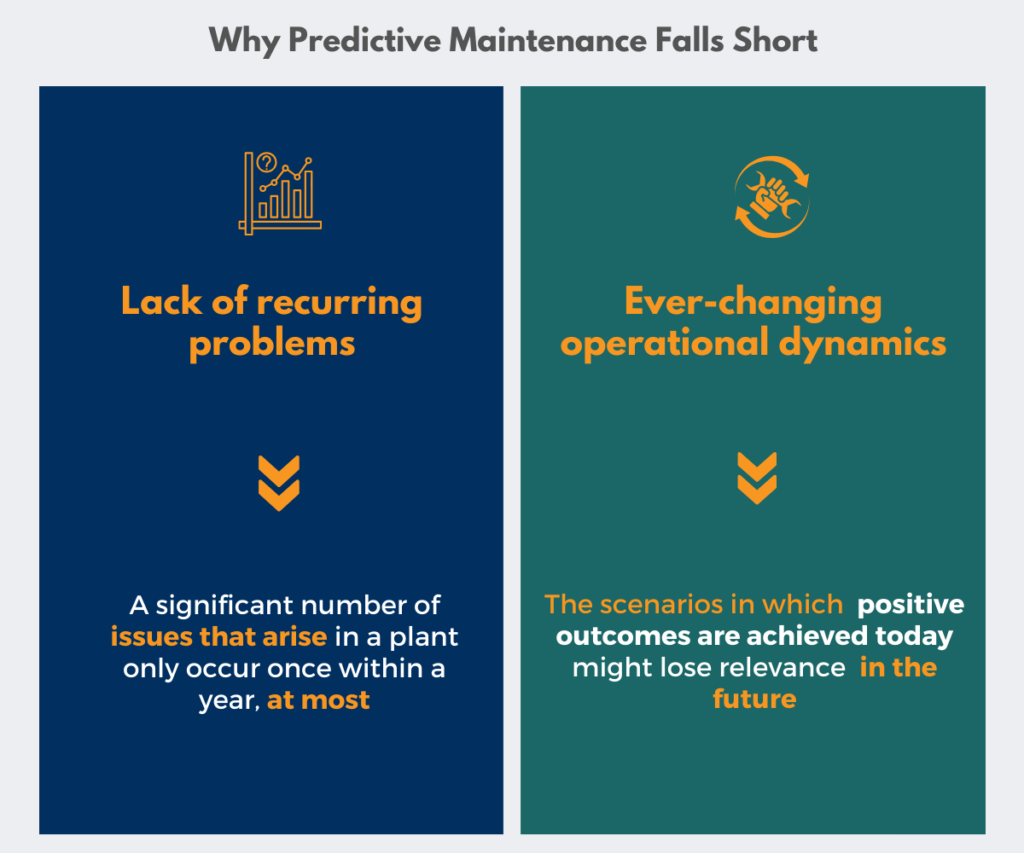

The central issue isn’t necessarily the technology itself. Rather, it’s the inherent challenges posed by manufacturing environments. The lack of recurring problems, difficulty in keeping precise records, and ever-changing operational dynamics make accumulating enough relevant examples for confident predictions a daunting task. For instance, in our own experience, we’ve arrived at a rule of thumb that you need 10 samples or instances of a behavior for classification to be effective. And yet, obtaining even 5 examples can be quite challenging for most manufacturers. A significant number of issues that arise in a plant only occur once within a year, at most.

Adding to this challenge is the dynamic nature of plants, which undergo frequent changes. The scenarios in which positive outcomes are achieved today might lose relevance in the future due to alterations in production lines. Consequently, the behavior of these lines can deviate significantly from the originally modeled patterns. Simply put just like there is no general artificial intelligence, there is no general predictive maintenance, at least not yet!

Predictive Maintenance in Manufacturing: Promise vs Reality

As Terrence O’Hanlon from ReliabilityWeb puts it,

“There are two kinds of Predictive Maintenance ‘predictions’

Type 1) The bearing will fail in the next two years – way too vague to be practically useful

Type 2) The bearing will fail soon – vague, but possibly useful depending upon shutdown schedules, production requirements, asset criticality, asset health and other factors.”

These predictions aim to estimate the potential failure horizon of an asset or component, relying on generalized data and patterns. This aspect stands as one of the primary drawbacks of predictive maintenance – a “one size fits all” approach that often struggles to adapt to the distinct characteristics of different equipment and systems.

Drawing parallels to medical diagnostics underscores the limitations of this method. In the same way that doctors diagnose based on individual test results instead of generalizations related to larger populations or demographics, manufacturers should employ advanced monitoring and diagnostics to discover/extract signs of impending failures.

The Rise of Anomaly Detection

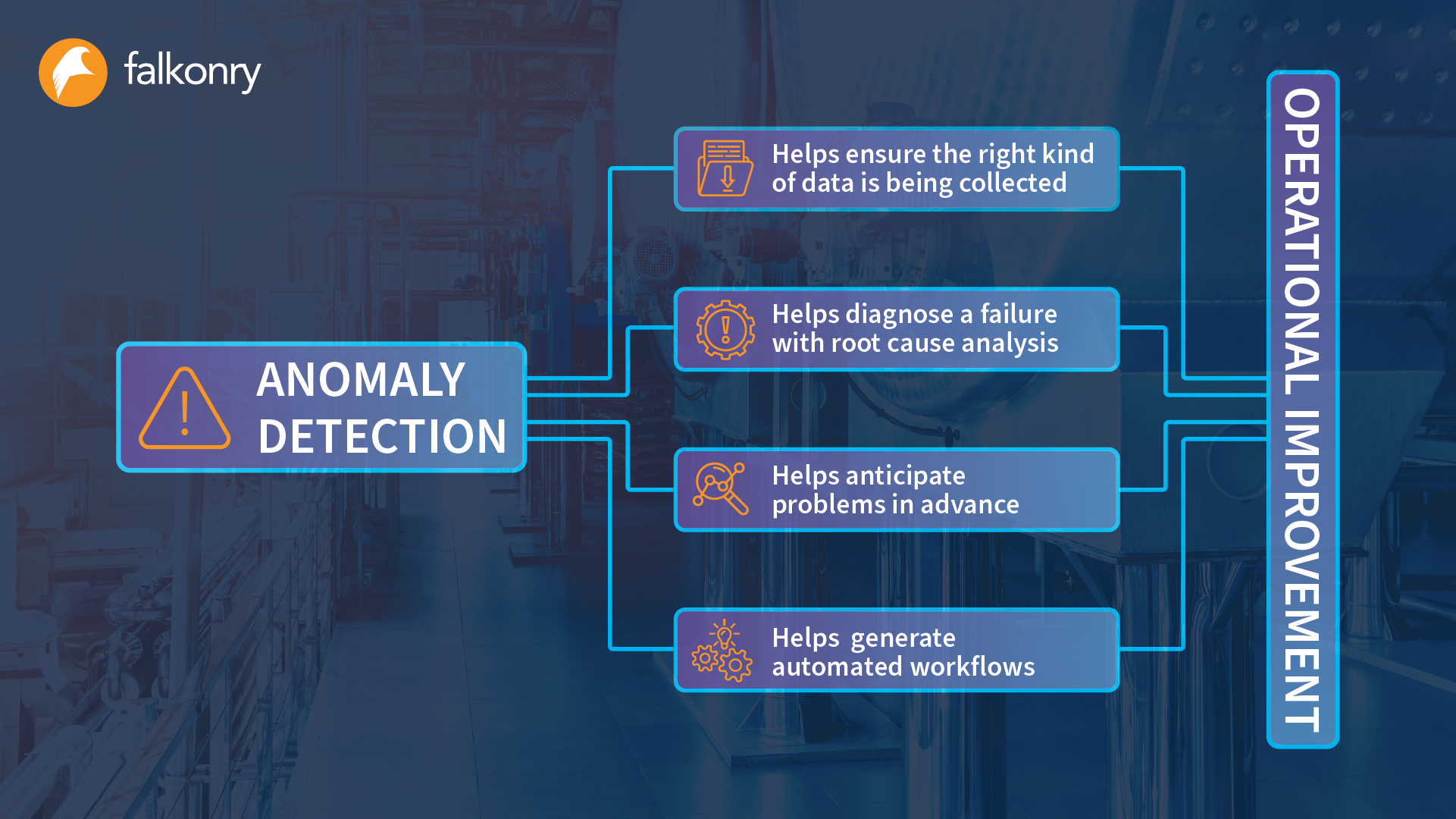

While achieving a predictive operational state with timely warnings of equipment failure might be your ultimate objective, it shouldn’t form the foundation. Instead, the cornerstone should be anomaly detection, an approach aimed at minimizing excursion risks and enhancing the efficiency and productivity of technicians and engineers.

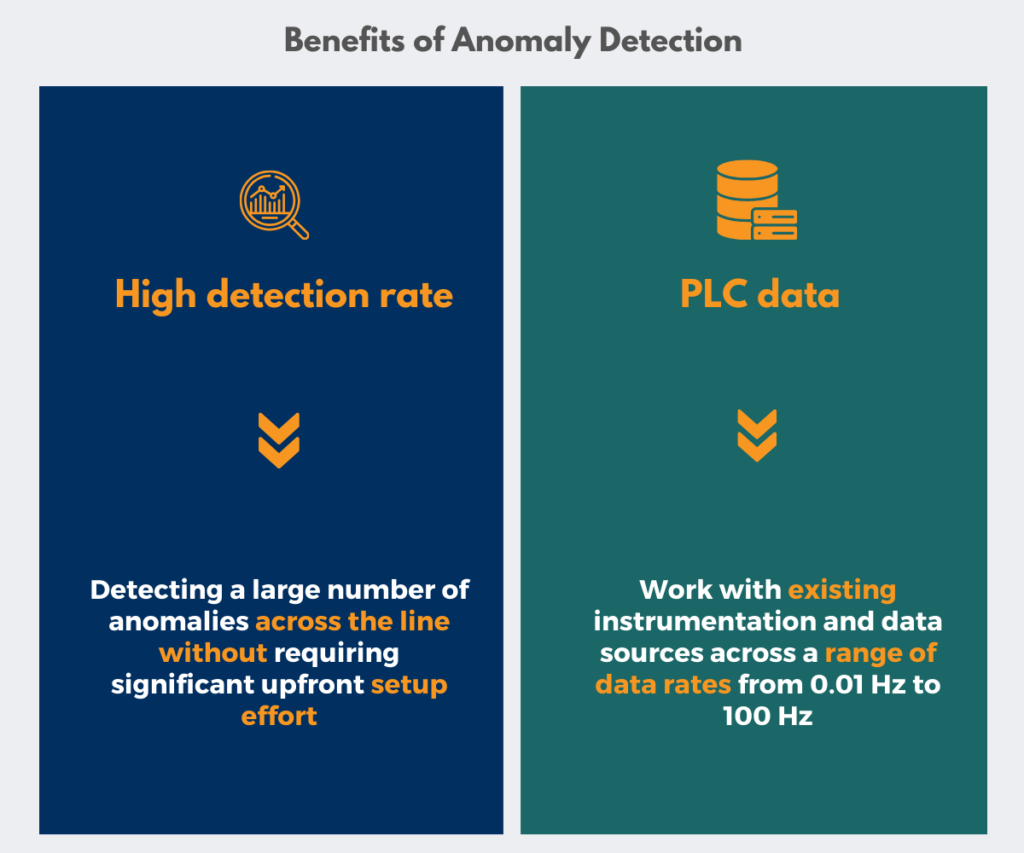

Through continuous identification of excursions across the board, a proficient anomaly detection system can alert operators even before the initial instance of downtime occurs in most cases. By taking into account all available equipment parameters and not struggling with data dropout issues, anomaly detection offers a more adaptive and effective solution.

This method offers broader coverage, as it relies on learning from normal behavior rather than focusing on specific patterns of interest. Consequently, this approach is not limited by the availability of predictive data and it significantly cuts down the time engineers spend on troubleshooting, seeking solutions, and recovering from issues.

We have been firmly advocating anomaly detection as the more effective strategy for achieving smart operations. The shift toward smart operations calls for a method that avoids the need for deploying extensive IT resources. Distinguishing this approach with predictive maintenance – where computers are expected to have all-encompassing knowledge – anomaly detection operates on the premise that computers understand instrumented behavior. The contrast is stark:

Predictive Maintenance Approach:

- Relies on data science features and professional services for targeted use cases.

- Involves a team of data experts to harvest knowledge of plant teams.

- Requires projects, consultants, and often a large IT workforce.

Anomaly Detection Approach to Smart Operations:

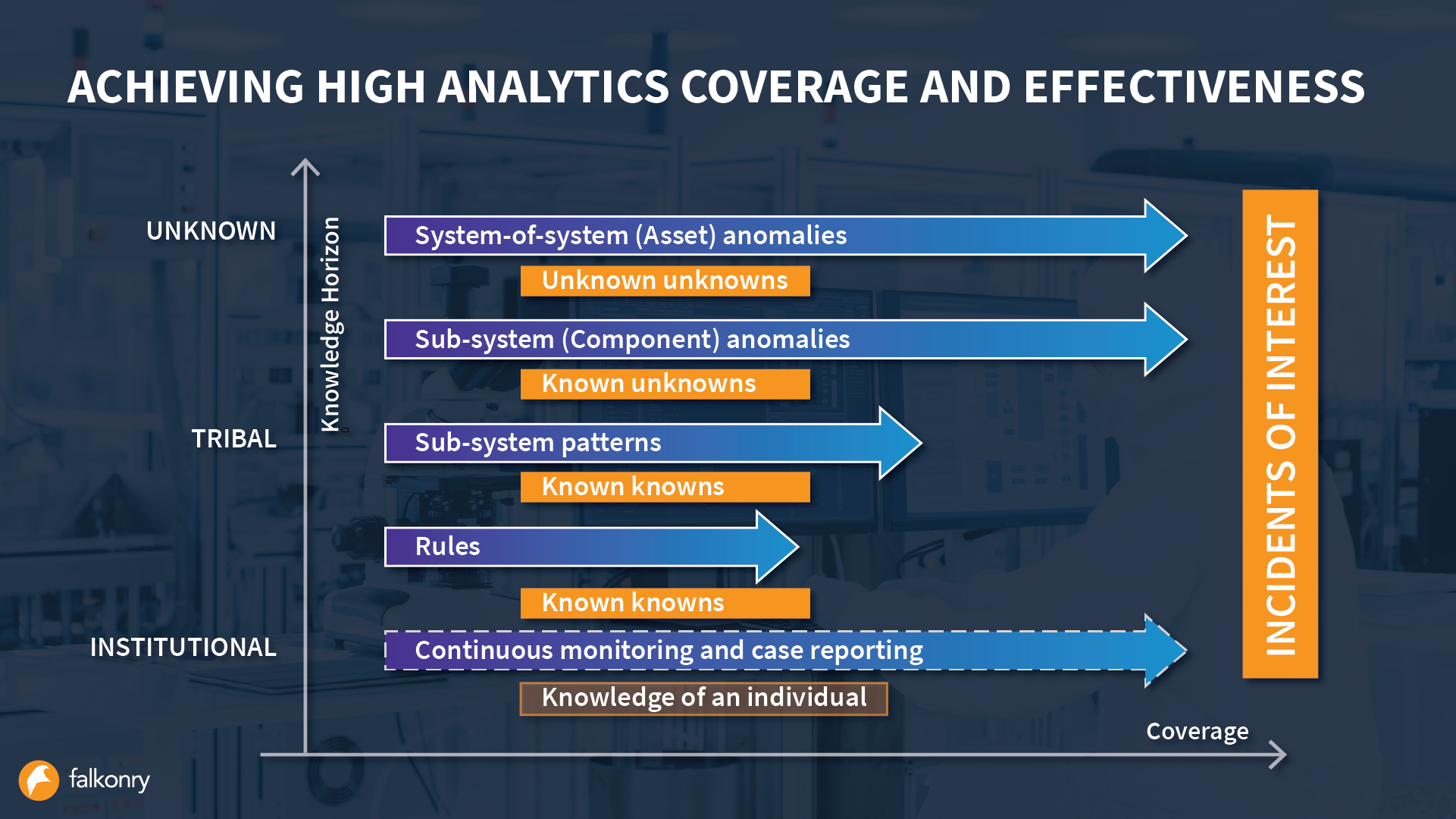

- Employs AI to learn known knowns, known unknowns, and unknown unknowns.

- Enables plant teams to self-serve and pool tribal knowledge.

- Offers products and scaled applications guided by experts focused on achieving success.

Rethinking Predictive Maintenance in Manufacturing

The appeal of predictive maintenance in manufacturing is understandable, but its limitations and implementation challenges have led it to a point of stagnation. Even if predictive maintenance might not be feasible at the moment, predictive analytics remains viable.

With anomaly detection, you’re constantly predicting what will happen next, and comparing it against what actually happens. If the two values are not the same, that means there is an anomaly. Rather than predicting when to perform maintenance, you’re simply predicting what happens next. In the process, you are illuminating to the right people where attention is needed, why it is needed, and equipping them to learn from the incidents.

The pursuit of individualized fault detection and resolution, rather than broad failure predictions, aligns more closely with the goals of efficient maintenance and reliable operations. As the manufacturing landscape evolves, the shift towards anomaly detection and Smart operations promises to redefine how maintenance professionals ensure optimal performance of equipment and systems.

If you would like to experience how anomaly detection can benefit your operations and bring you one step closer to Smart operations, schedule a demo today.

[Note: A version of this blog first appeared on IIoT World]