Rethinking Time Series AI

Key takeaways:

- In a field where technology decisions take years and remain in use for decades, we find that substantially lowering the time-to-first-value can reduce risks for both technology developers and adopters.

- We are fundamentally rethinking time series AI and how it is applied to production operations by lowering time-to-first-value from months to days.

- Reducing time-to-first-value enables plant and manufacturing executives who believe in the potential of operational AI to prove their intuition quickly and with much less risk.

It is a well-accepted premise that operational data contains patterns – evidence of system behaviors including early warnings and root causes. That premise is the basis for remote monitoring, Industrial IoT, and predictive operational excellence.

It currently takes 3 to 5 years and tens of millions of dollars to execute manufacturing digitalization projects, requiring large teams of practitioners in three or more skill categories (data engineering, data science, software management). It is a high-risk endeavor that may be feasible in an easy money economy. However, this is unsustainable and very often results in difficulties progressing past the pilot phase.

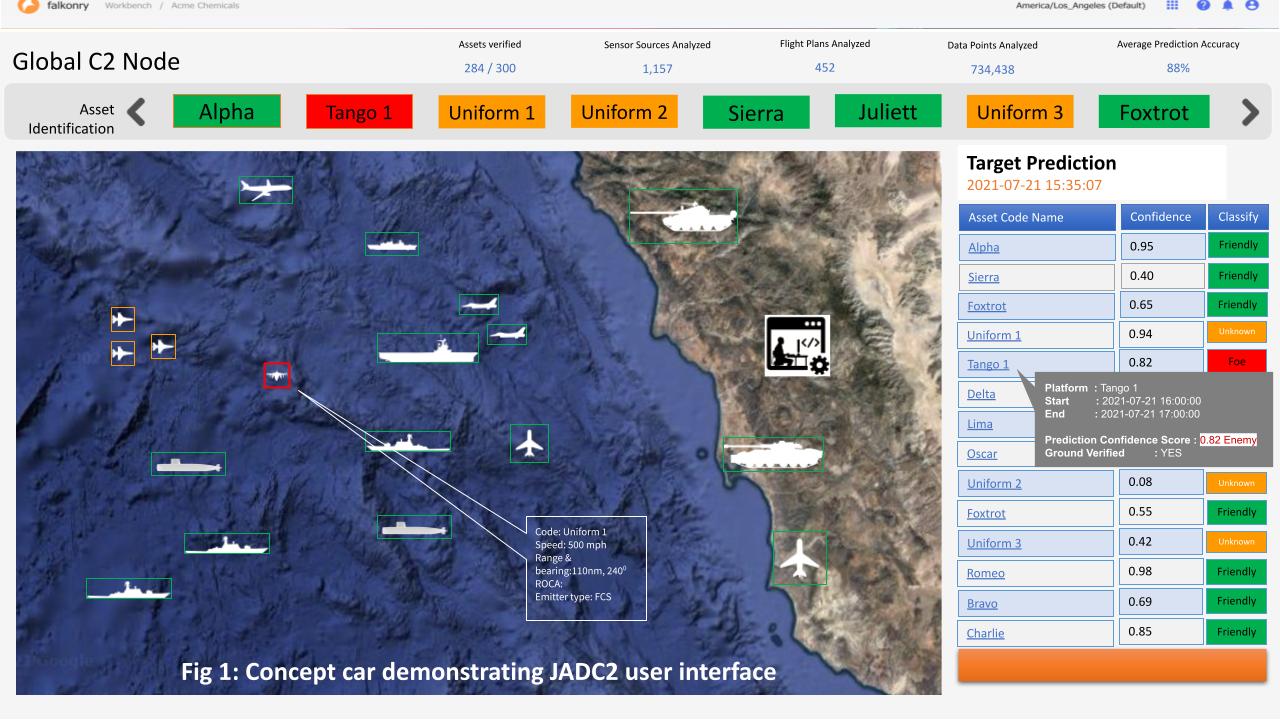

Falkonry has helped customers overcome these difficulties with its time series intelligence tool, which enables scale by focusing on citizen data science. Existing analytics target shapes, waveforms, and features that can be visualized but only Falkonry automatically discovers the characteristics of operational data that matter and explain how and how much they matter. This is the core innovation behind our 4 issued patents. That is also the basis of being named in the 2019 and 2020 CBInsights AI 100. That is the reason the US Air Force has selected Falkonry as a strategic program to expand deployment of AI technology to additional Department of Defense (DoD) customers. With Falkonry, manufacturers have been able to develop and deploy models in production within a single year. A $10B+ steel company is already achieving such results using Falkonry’s time series AI across dozens of use cases at a 10 times faster pace than alternative approaches. While this degree of success is best in class, for mainstream pursuit of predictive operational excellence, even this is not fast enough.

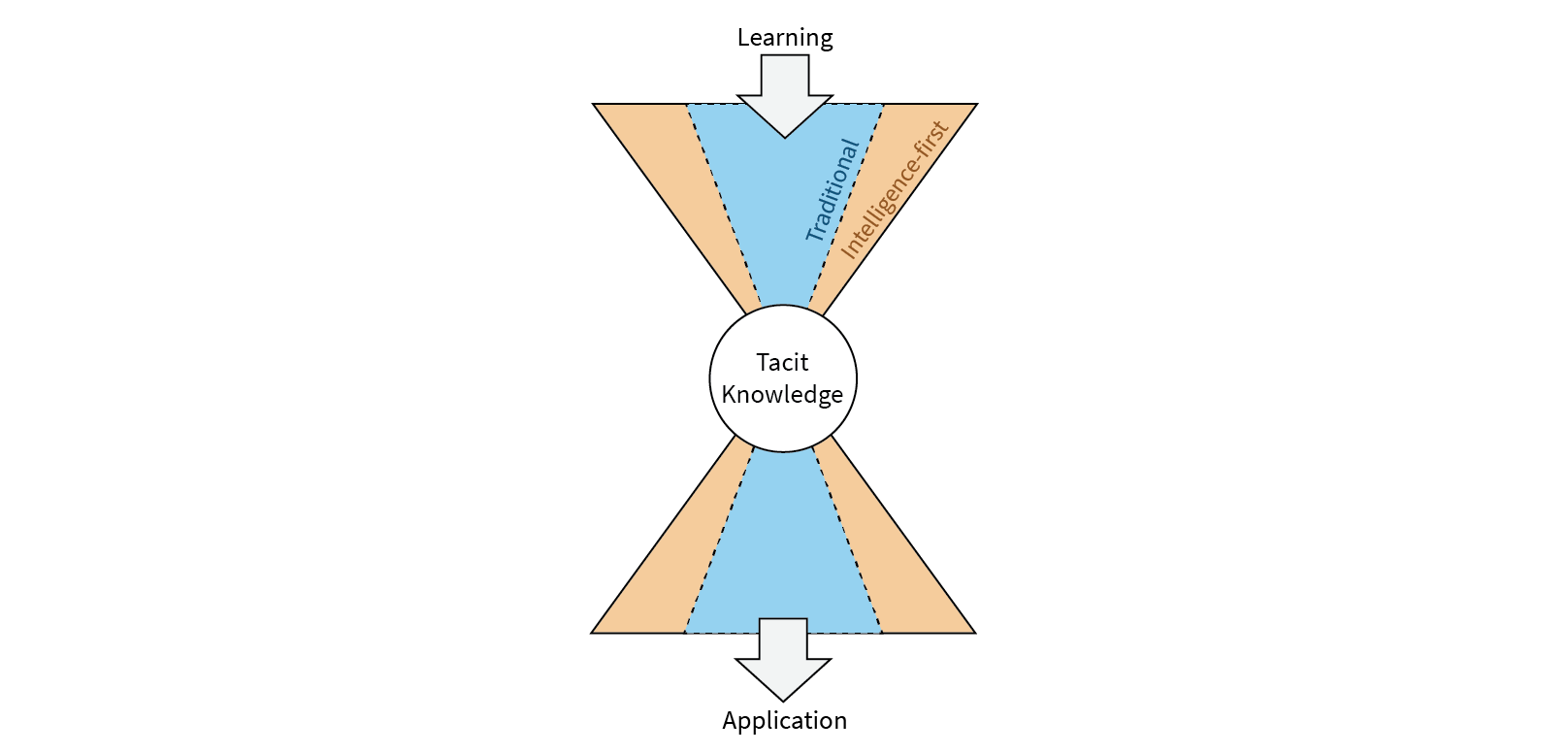

The main hurdle to success in speed as well as scale is the availability and collection of ground truth data. We have found no companies whose data resemble those used in mainstream machine learning, where reliable label information like clicks and purchases are recorded with high fidelity and in very large volumes. Many organizations lack processes and technology for accurately recording critical events. Most organizations lack a consistent nomenclature for talking about specific kinds of operational conditions and failures within a complex process.

Predictive operational excellence sidesteps this problem by collecting information about failure context in real-time. Plants are notified with early warnings of undesirable events and perform root cause analysis from these early warnings with guidance from patterns discovered in the data using the AI. Often this can be done even before events impact their operations. Because such insights are generated from current operational data rather than as a result of analyzing old data, plant engineers are far more likely to validate and benefit from the findings. This creates the desired time-to-first-value for the digital manufacturing organization.

In this new way, we at Falkonry are rethinking time series AI: no data scientist, no data engineer, no system integrator is required. That means a plant can be hooked up to the AI system within hours. Insights are available well before issues begin affecting production. Within days, plant engineers start to receive value from Falkonry’s time series AI. Feedback is received from plant engineers by a learning system that improves the insight generation process immediately. This method can be simultaneously applied to dozens of different use cases and value is created much faster in each of these use cases. The marginal cost of predictive analytics in this method is essentially zero.

Over the last 3 years, we have worked across 12 industries, including manufacturing and national security, with more than 60 customers on over 250 use cases. The key lesson we have taken from this is that a time series AI platform which is able to produce insights from little to no historical data and effortlessly take expert feedback on these insights, is the only way customers can deploy and benefit from a wide range of use cases in a short time.

The reduction in time-to-first-value will remove many remaining hurdles to scaled deployment. Plant managers can implement such a method without asking for significant corporate resources, plant engineers can discover insights and improve production, and manufacturing leaders can manage the process of recording and leveraging expert knowledge.

This is what the state of the art looks like and how we, at Falkonry, are changing the conversation around digital manufacturing. Watch this space as we are deep into this transition and will share our findings with you.