Leveraging Anomaly Detection For Operational Improvement

Key takeaways:

- Anomaly detection is the starting point; understanding the significance of anomalies and taking action is where the real value lies in optimizing manufacturing operations.

- Anomaly detection creates the foundation upon which organizations can build their analytics capabilities. Skipping this step to directly seek predictive insights generally leads to wasted effort and resources.

- By leveraging anomaly detection, manufacturers can proactively address operational issues as well as improve their understanding of the root causes of their operational challenges.

It is generally known that there are operational anomalies and some of them lead to production problems. Therefore, it is valuable to detect meaningful anomalies. However, simply identifying anomalies is not enough. The real value lies in understanding what comes next – what actions should be taken when anomalies are detected and how they can lead to significant improvements in operations. In this blog, we explore the next steps following anomaly detection and examine how anomalies can assist you in attaining your smart manufacturing goals.

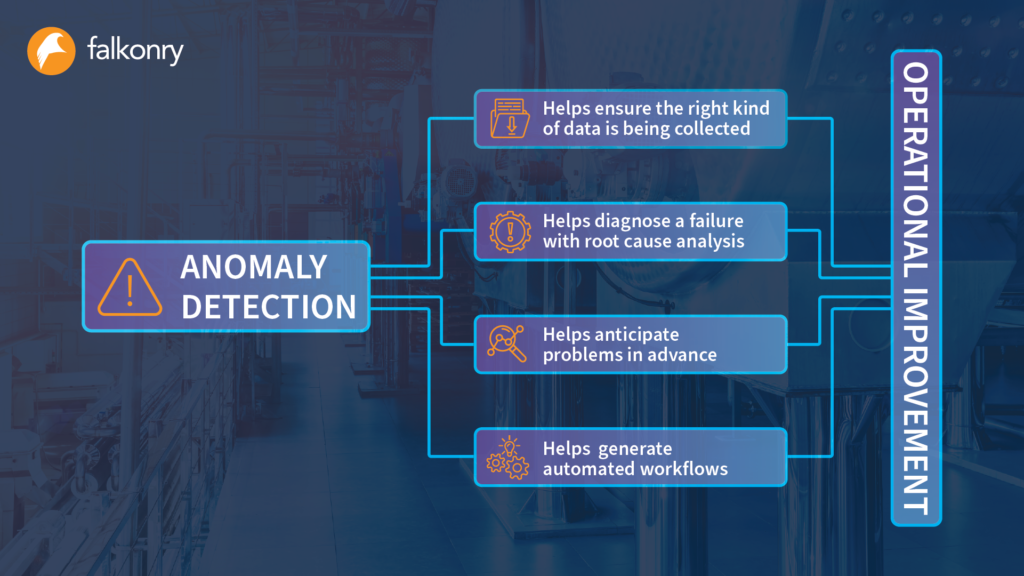

How to get from anomaly detection to operational improvement

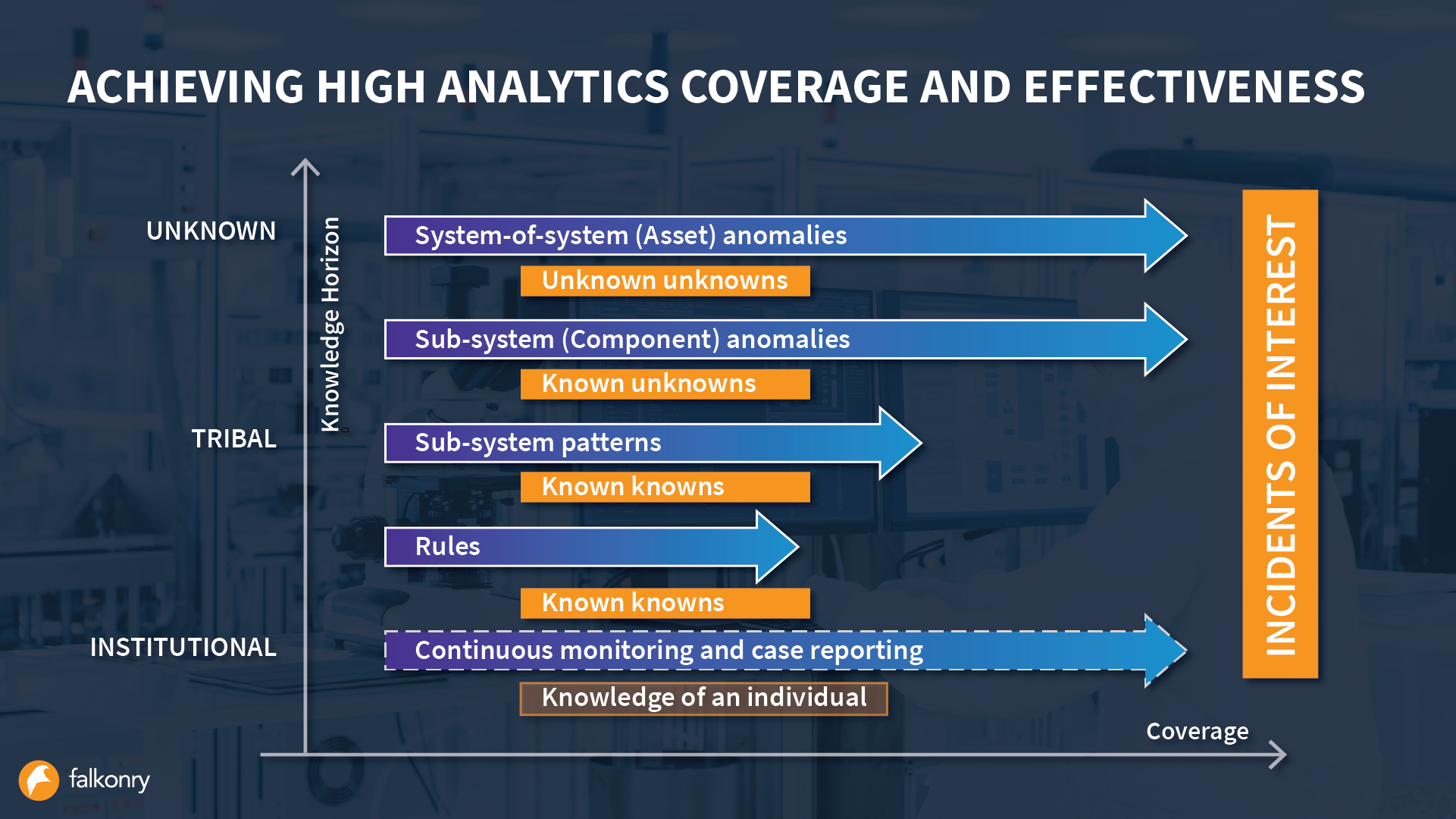

We’ve created a comprehensive roadmap that provides a unique approach to solving productivity and complexity challenges in the manufacturing industry. It shows a clear path for how manufacturers can harness the full potential of their operational data, uncover hidden insights, and make informed decisions – the entire basis for which is anomaly detection. If you haven’t already, we highly encourage you to go through this smart pyramid framework in order to fully appreciate the role anomaly detection plays in building a strong analytics foundation for your organization. Anomaly detection remains our core focus and we’ve perfected it to a point where it is incapable of missing anomalies. This AI-based anomaly detection is capable of discovering abnormal operations that are well within the upper and lower control levels – something conventional methods cannot do. And yet a pertinent question that comes to mind at this point is – what do I do with the anomalies? Well, an important prerequisite lies in recognizing that anomalies are not just isolated incidents but gateways to valuable institutional knowledge. There are four benefits that can be derived from identifying anomalies, leading to tangible operational improvements:

Ascertaining whether the right kind of data is being collected

The first benefit of anomaly detection is to gain confidence that the right data is available for smart manufacturing. If the data being sourced is not immediately analyzed, we are likely collecting data that may never be useful. Manufacturers often can’t instrument their systems to source all the data they may need. When the need arises to understand the cause behind an event, they often battle the invisible question – will they be able to do so from the data being sourced? Often investigations are not even pursued due to uncertainty about data. For smart manufacturing to happen, one can’t make choices simply by relying on experience rather than concrete evidence. By utilizing Falkonry’s granular anomaly detection capabilities, manufacturers can see what relevant data they have pertaining to any event, including if they don’t have it or don’t have the right sampling strategy. This enables them to make informed decisions about additional sensors and data collection strategies, optimizing their ability to uncover valuable insights. In a data-driven world, knowing if relevant data exists is a prerequisite for smart manufacturing, and Falkonry can help address this challenge with its plant-wide anomaly detection.

The ability to diagnose a failure with root cause analysis

One of the most important responsibilities of process engineers is to perform root cause analysis on production-impacting events. However, due to the ever-increasing complexity of manufacturing processes, process engineers are constantly overwhelmed by the volume of events to analyze and the time and effort it takes to complete even a single root cause analysis. The result is that the plant improvement stalls and expertise development goes for a toss. However, anomaly detection can automatically package the data to answer the where, when, and why of an event and get root cause analysis going. Engineers can then confirm this package and add their root cause knowledge about cause-effect to complete the analysis and provide recommendations. Readers of the root cause analysis can observe behavioral patterns and their precursors to better understand the origins of problems. Falkonry’s anomaly detection capabilities enable faster root cause analysis, reducing the time required from days to just about an hour. This changes the lifestyle of process engineers who go from being a source of anxiety and frustration to becoming the font of knowledge and a source of learning. It also accelerates expertise development and scales the ability of this scarce resource.

Anticipating problems in advance

Anomaly detection goes beyond identifying current issues; it also provides a unique opportunity to anticipate and prevent future problems. By analyzing all available data, manufacturers can identify patterns and behaviors that precede anomalies. For example, working with one of our existing steel customers, we were able to accurately attribute the cause of a failure of a rolling mill to a malfunctioning roller. This ability to detect malfunctions in advance provides crucial early warning to take preventive action. While it involves reviewing heatmaps and therefore may be limited to a small number of plant personnel, this function can be easily centralized. In fact, quite a few Falkonry customers have established such operations service centers to review anomalies and provide guidance to remote operating teams about potential trouble.

Generating automated workflows from anomalies

Once manufacturers develop confidence in the AI’s ability to identify relevant behaviors, they will be able to turn anomalies into actionable triggers. This will generally unfold one trigger at a time since anomalies are one-off. These triggers can initiate maintenance workflows, such as investigating faulty components or implementing necessary repairs. In the case of the faulty roller, the corrective action was to simply lower it for the time being and schedule maintenance of the motor at a convenient time that causes no disruptions. By acting proactively, manufacturers can avoid such production disruptions, minimize downtime, and optimize their overall operational performance. Falkonry is working with partners to integrate the results of anomaly detection into existing organizational systems. By delivering work orders, alerts, or notifications directly to the appropriate personnel, plant managers can efficiently execute the necessary actions. This integration can be achieved through Enterprise Asset Management (EAM), Computerized Maintenance Management System (CMMS), email alerts, and other relevant means. By automating the maintenance workflow, manufacturers can save time, reduce human error, and ensure that the right actions are taken promptly.

In the quest for manufacturing excellence, embracing the power of anomaly detection is a pivotal step. By starting with anomaly detection and exploring the layers of the pyramid framework sequentially, manufacturers can unlock new levels of productivity in their operations. By collecting the right data, speeding up root cause analysis, anticipating problems in advance, and generating automated workflows, manufacturers can optimize their operations and drive significant improvements.