Event Horizon Estimation – Time to Any Critical Event

Key Takeaways

- Event Horizon Estimation (EHE) builds upon real-time condition monitoring to predict time to failure (TTF) and remaining useful life (RUL)

- EHE enables operations teams to balance intervention efforts with production schedules and planned maintenance windows

- EHE is available to Falkonry Workbench users and can be exported as an Analyzer just like condition classification

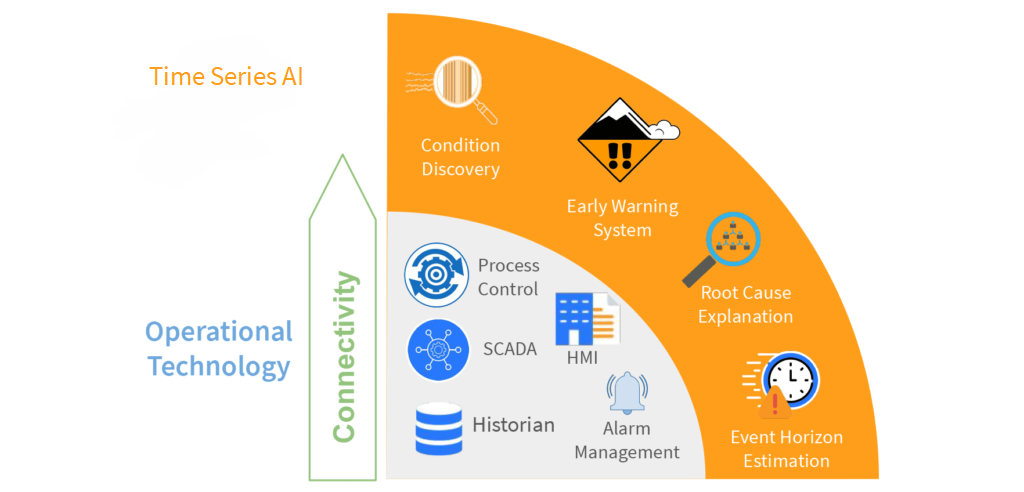

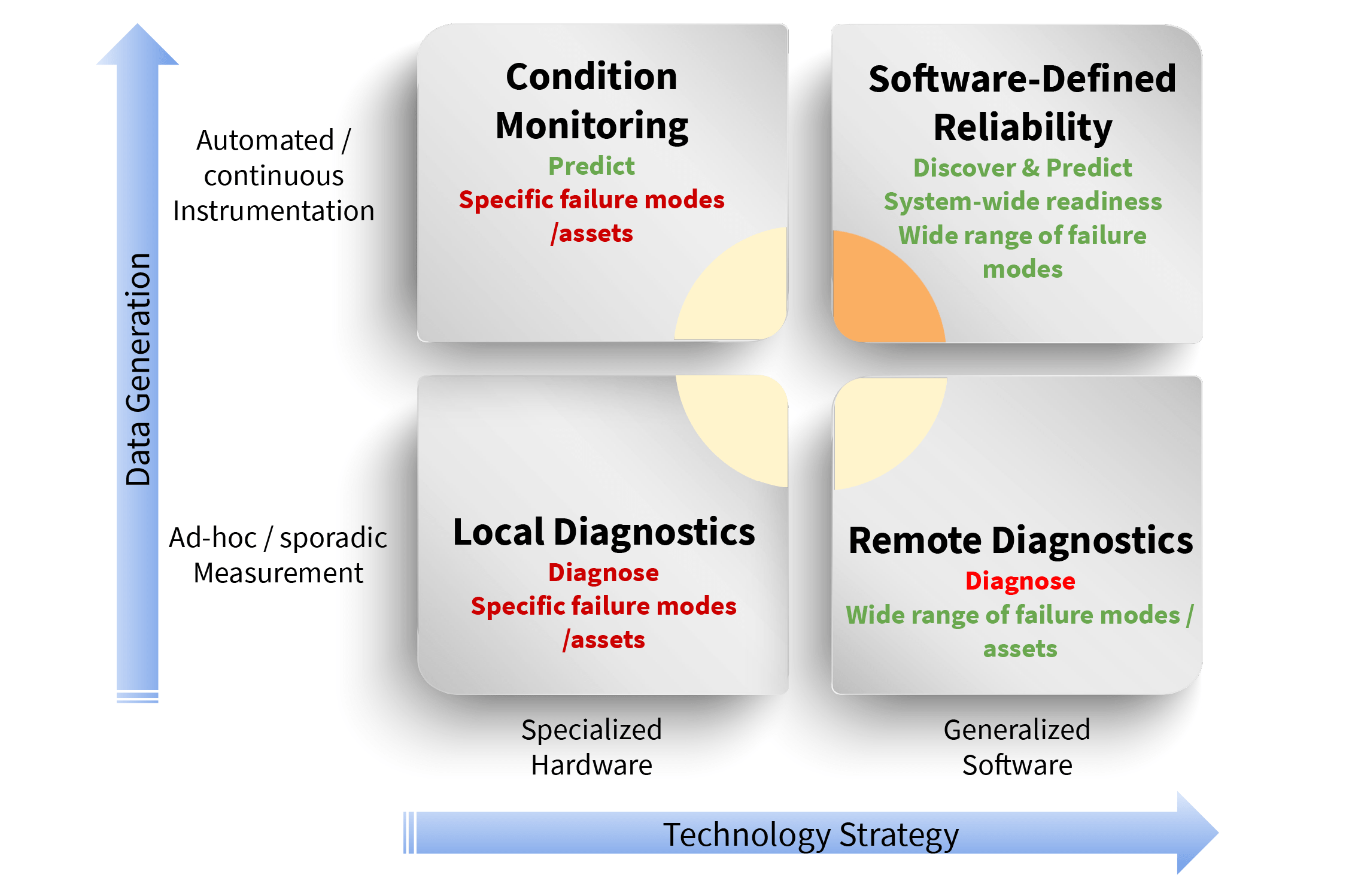

Falkonry has added Event Horizon Estimation to its time series AI capabilities. “Events” are behaviors of interest where the time until occurrence is important to know. We use this more general term because we have seen that, in addition to time to failure (TTF), operations teams try to estimate the time until other events such as the time to reactor criticality, the time to product release in a chemical reaction, the life of a consumable (RUL), and so on. Falkonry’s approach to making these time estimates provides users with a single method to solve multiple problems rather than requiring them to experiment with different mathematical models and error estimation mechanisms. This further reinforces Falkonry’s position as the innovation leader in time series AI.

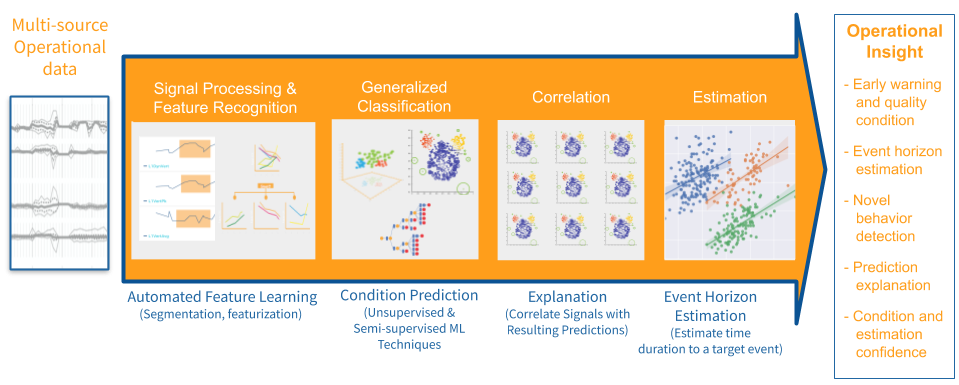

A major difficulty in TTF and RUL estimation techniques is identifying when degradation, as shown in Figure 1, has begun. Traditional regression techniques do not work in cases where the pattern of failure is complex. For processes and assets which exhibit this kind of wear, a very common occurrence, it is important to be able to determine when the equipment has entered a state where failure trends can be seen. This is, in itself, a difficult task but is one which Falkonry has solved with a pattern discovery and recognition system. By building on top of this capability, Falkonry is able to provide more accurate time estimates for a range of events. Falkonry’s unique approach and patent-pending technology advances the state-of-the-art in prognostics and health management (PHM).

Operations teams need a good understanding of how much time they have in the P-F interval in order to minimize production disruption while achieving required equipment performance. In practice, Falkonry alerts with early warning on potential failure (P) very soon after the actual start of failure which is an important first step. With EHE, Falkonry produces an estimate of the P-F Interval for any target event F (e.g. the functional failure). This provides operations teams the ability to more effectively balance intervention efforts with production schedules and planned maintenance windows.

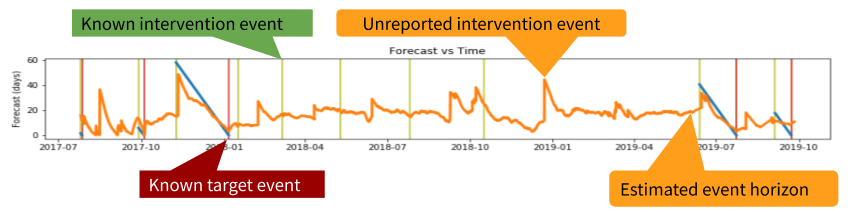

We define Event Horizon to be the length of time until the occurrence of some target event, such as a system failure or of a system reaching a readiness level. As shown in Figure 2, this estimate (shown in orange) fluctuates as operating characteristics change and as intervention measures are taken. The estimated time to event, i.e. the event horizon, (shown in blue) decreases as we approach target events and resets after interventions. Changes in operating characteristics impact how target events unfold. Therefore, reliability of any estimation approach requires a dynamic calculation that accounts for these changes. For example, a change in the recipe being applied in production can markedly increase component wear causing a decrease in the event horizon estimate.

As shown in Figure 3, Falkonry’s AI engine was extended to produce time estimates in addition to warnings about the operational condition. An event horizon estimate is produced from historical operational data and known occurrences of the target event. EHE models can be created for new assessments or be added to existing Falkonry condition models. Each EHE model produces an estimate for a specific behavior or target event. A validated Event Horizon Estimation for such a target event can be exported from Workbench as a Falkonry Analyzer. This Analyzer can receive real-time operational data to produce the corresponding time estimate for the corresponding target event.

In addition to helping reliability teams make decisions about when to perform maintenance, the Event Horizon Estimation also provides a method to confirm maintenance procedures and to correct operations records. A sharp rise in the estimated time before an event usually indicates that an intervention, such as part lubrication occurred. A sharp reduction in the estimated event horizon could mean that a process change was made, such as the addition of a catalyst to accelerate the reaction. Even if neither event was logged, the Event Horizon Estimation provides evidence that a change occurred and serves as a reference for investigation.

With this game changing development, time series AI can be even more effectively applied at scale and its results incorporated into enterprise operational planning. Let us talk if planning is an important part of your predictive operations objectives because event horizon estimation will be critical to planning. Arrange a discussion and learn about how to get started.