Webinar: Advances in Industry 4.0 & The Industrial IoT

Watch Now

Watch NowWe have previously explained how software-defined reliability provides more flexible warnings of impending functional failures than do specialized hardware methods. In this post, we introduce another software-defined reliability technique that greatly enhances our ability to increase OEE without the need for additional instrumentation or capital investment. This technique, called Event Horizon Estimation, enables operations teams to estimate the time until important, process affecting events occur in order to prioritize interventions thereby minimizing unplanned and planned downtime. Falkonry is able to provide more reliable time estimates for a range of target events. For example, a target event may be a functional failure. In this case, the event horizon estimate gives the time-to-failure. In another instance, exhaustion of a consumable part is a different kind of target event. The event horizon estimate in this case is the remaining useful life.

Falkonry customers have validated EHE on real-world data and are now placing the capability into production. This capability is now available to all customers as part of Falkonry Workbench. Therefore, existing customers can get access to this exciting capability as part of their existing subscription.

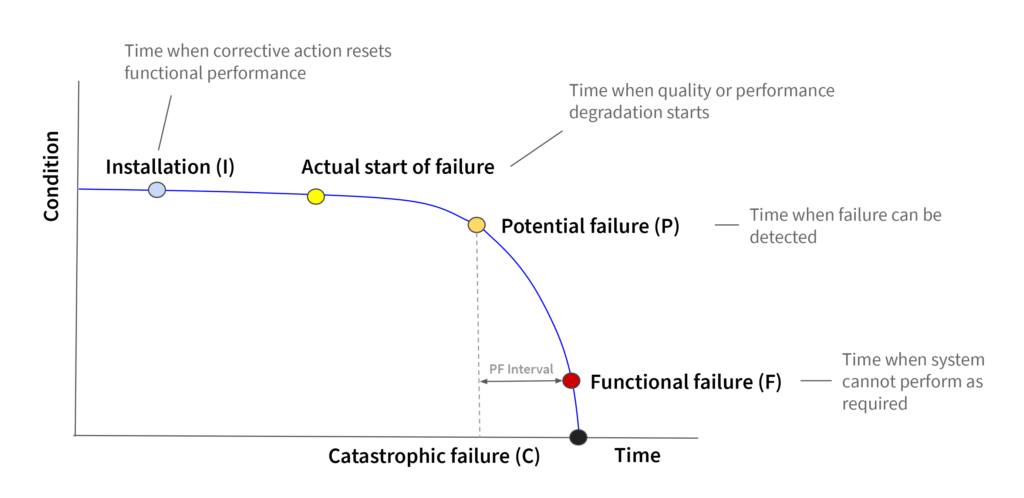

Why was this approach required? As per a report by the US Navy, NASA and others, 82% of failures in industrial assets are not wear or age related and operations want to reduce unplanned and planned downtime related to failure. The P-F curve is a common metaphor used to talk about failures in industrial systems. This metaphor identifies the prognostic horizon (PH) as the period between the actual start of failure (the incipient damage) and the functional failure (F), as shown in Figure 1. Prognostic horizon is not limited only to assets but can also be seen in systems and processes. For example, chemical processes have a prognostic horizon from the time the reaction starts to the point of product release.

Most prognostic horizons do not contain a straight line behavior or a smooth curve. The kinetics of that prognostic horizon depends on the mix of operating characteristics during that period, which makes it tricky to manage the asset or the process. To manage performance during this interval, we need to reliably know the operational state as well as forecast the time horizon for the target event.

Innovation and out-of-the-box thinking is acutely needed for this very reason. After introducing pattern discovery and explanation, Falkonry set about to improve the state of the art in event horizon estimation with a fundamentally different view of system dynamics in the P-F region to make it more general and reliable.

Falkonry’s Event Horizon Estimation, as part of our Time Series AI suite, is uniquely positioned to enable broad industrial transformation because:

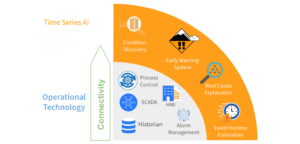

The main objective of Falkonry’s AI is to exploit operational data and operational knowhow to achieve and enhance operational excellence. The AI needs to offer a broad set of process and asset-agnostic capabilities. Falkonry has created such a suite of time series AI capabilities that includes novel condition discovery, early warning, root cause explanation, and now event horizon estimation. Figure 2 shows the capabilities of Falkonry’s Time Series AI suite.

Plant operations can improve reliability with time series AI. We welcome you to contact us for a conversation about how this would benefit your plant and enterprise.