Accelerated AI Activation: The Seamless Integration of iba and Falkonry

Key takeaways:

- Managing the vast volumes of time series data generated by industrial operations is not easy; it often necessitates dedicated data engineering teams.

- To harness valuable insights from this time series data, data integration is crucial for northbound connectivity – a challenge which iba AG has effectively addressed.

- Falkonry’s Time Series AI Cloud is compatible with iba, making it easy for enterprises in metals, energy and pulp and paper space to seamlessly connect and derive benefits from plant-scale AI analytics.

A significant hurdle in industrial AI deployment has long been the complex IT groundwork required to establish seamless data connectivity between physical systems and analytics solutions. The data itself is abundant, reflecting the exponential growth of time series data, now among the fastest-growing data types globally. Yet, leveraging this data for performing tasks such as high-speed trace analysis, depends heavily on its accessibility and availability. Effectively managing and reliably establishing connectivity for this data at scale, without extensive IT efforts, emerges as a pivotal factor in predicting the success of AI deployments. This crucial step of easy data integration paves the way for accelerated AI activation within industrial settings. It is a key enabler in harnessing valuable insights, streamlining processes, and enhancing decision-making through AI. To simplify this integration Falkonry and iba AG have combined their robust data acquisition and management capabilities, allowing industrial organizations to seamlessly implement AI within their existing infrastructure.

How does it work?

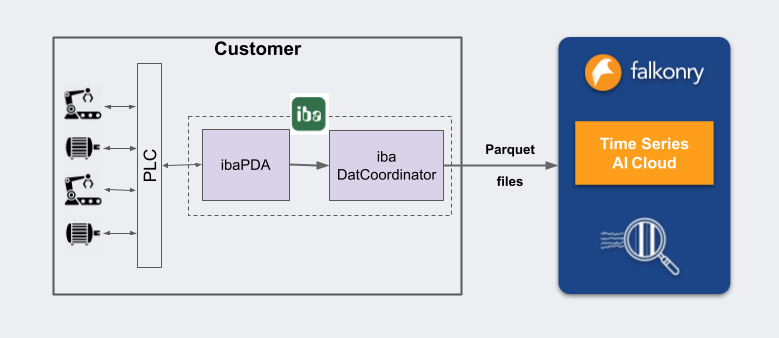

iba System is an autonomous, modular and scalable data acquisition system for machines, production lines, and plants. It can acquire, record, and make the operational data from PLCs available to cloud-based AI applications. Its modular design and simple configuration make the iba System easy to use and deploy in any industrial setup. The Falkonry’s Time Series AI Cloud compatibility with iba System ensures smooth, trouble-free integration, erasing uncertainty and effort from the equation. It can readily integrate with existing ibaPDA via ibaDatCoordinator, enabling organizations to discover insights from operational data effortlessly.

The Data Integration

The time-synchronous acquisition of operational data for a plant is the basis for all data analysis. The iba System records and stores measurement data continuously for up to 100kHz. As the central core of the iba system, ibaPDA is responsible for data acquisition, and high-speed synchronous archiving. ibaPDA connects and acquires signal data from all the digital control systems via standard system interfaces. The ibaPDA archives the signal data across all the modules and channels in the form of files. The archived files contain the signal readings as operational data making them ready for AI analysis. To send this operational data out of the OT network, iba System uses ibaDatCoordinator. The ibaDatCoordinator is responsible for northbound connectivity by connecting to various cloud services and databases. This solves the connectivity problem for enterprises wanting to use Falkonry for AI analysis and extracting insights from operational data.

Connecting iba System with Falkonry’s Time Series AI Cloud

The connectivity recipe between iba System and Falkonry’s Time Series AI Cloud involves a simple one-click configuration step which enables ibaDatCoordinator to send the data to Falkonry. The modular design of both the systems opens up an opportunity to have multiple connectivity options. One such option is file-based data transfer between the two systems. File-based data transfer offers the advantage of not requiring the iba System to be always connected for continuous data streaming. Additionally, the industrial plant does not require a high-bandwidth network connection. This option is also simple to configure, meter and use, enabling the reliability and maintenance teams to continue to focus on AI insights for process optimization without worrying about the data infrastructure.

Establishing connectivity between the two systems is a simple two step process that involves creating an iba connection in Falkonry’s Time Series AI Cloud and configuring the ibaDatCoordinator to send data to the iba System connection. The initial step involves a straightforward, one-click process to create an iba System connection through the Falkonry UI. Once the iba System connection is created, secure credentials are downloaded for configuring the ibaDatCoordinator.

Finally, ibaDatCoordinator is configured to convert ibaPDA file recordings into the parquet file format and transfer these parquet formatted files to the Falkonry-hosted or customer-hosted cloud storage. Subsequently, the iba System connection in the AI Cloud automatically discovers and processes the parquet files as they arrive in the configured cloud storage. The iba System connection keeps track of all the files in the order of their arrival with relevant stats and processing status. Any delays in the data transfer, connectivity issues or data processing discrepancies can also be audited via Falkonry connection UI.

Leveraging Seamless Connectivity For Accelerated Insights

In addition to transmitting signal data, the iba System also relays metadata information about each signal and logical grouping to Falkonry’s Time Series AI Cloud, facilitating AI analysis through the same connection. The quick and effortless activation process underscores Falkonry and iba AG’s commitment to helping manufacturers remain competitive by prioritizing quick connection, analysis, and insight derivation. The two systems, while complimenting each other with their unique value proposition ensure that data connectivity is secure, reliable, scalable and capable of handling large volumes of data across plants. By addressing challenges head-on and recommending best practices, Falkonry enables its customers to unlock the full potential of their time series data.