Quantifying the Impact of Anomaly Detection

Key takeaways:

- Anomaly detection is vital for achieving Smart operations, and the Beneficial Detection Rate (BDR) emerges as a key success metric to measure its impact

- BDR serves as a reliable indicator of the AI's contribution to operational improvement

- Combined with trust in AI findings, a robust BDR becomes a catalyst for adoption

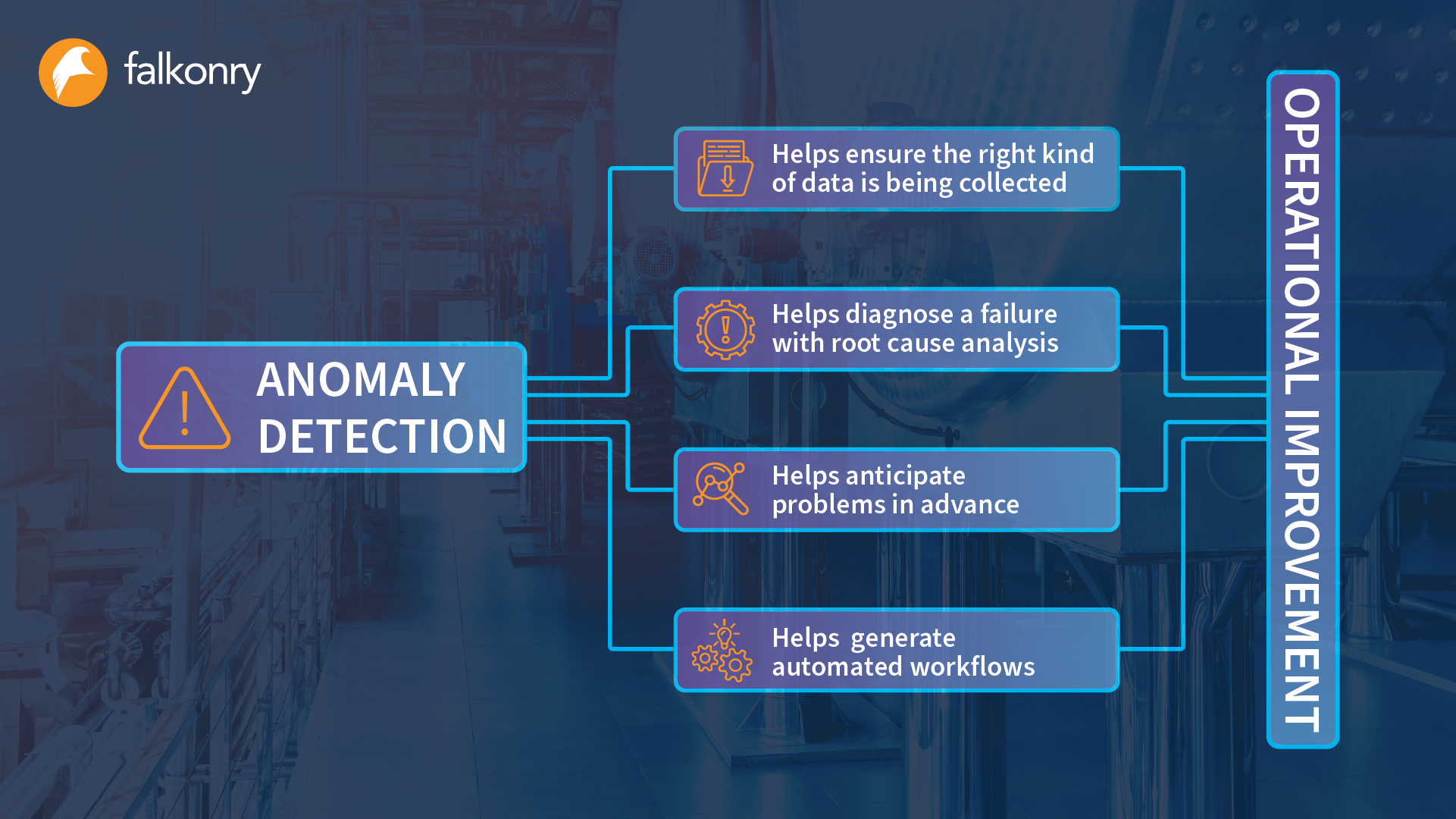

There’s a great deal of excitement about anomaly detection as the most effective path to achieving Smart Operations. Anomaly detection is taking center stage for good reason, promising to take industrial performance to new heights. But amid all the buzz, a pressing question remains: How can we quantify the impact of anomaly detection or AI in general? The answer to this question lies in a metric known as the Beneficial Detection Rate, i.e. the rate at which detection is successful in identifying an event while it is happening.

A Journey Toward Smart Operations

Anomaly detection isn’t just about identifying irregularities; it’s about pinpointing anomalies that can genuinely impact your operations. The key to assessing anomaly detection effectively is understanding its performance in terms of beneficial detection – detections that offer a high likelihood of operational benefits. A high number of beneficial detections reduces the payback period for the adoption of anomaly detection.

Defining Beneficial Detection Rate

The “Beneficial Detection Rate” (BDR) allows manufacturers to quantify the impact of their anomaly detection efforts. This success metric measures the ratio of beneficial events detected by AI as a percentage of the events independently observed. It’s a concrete and actionable indicator of the outcome of AI that contributes to operational improvement.

Calculating the BDR

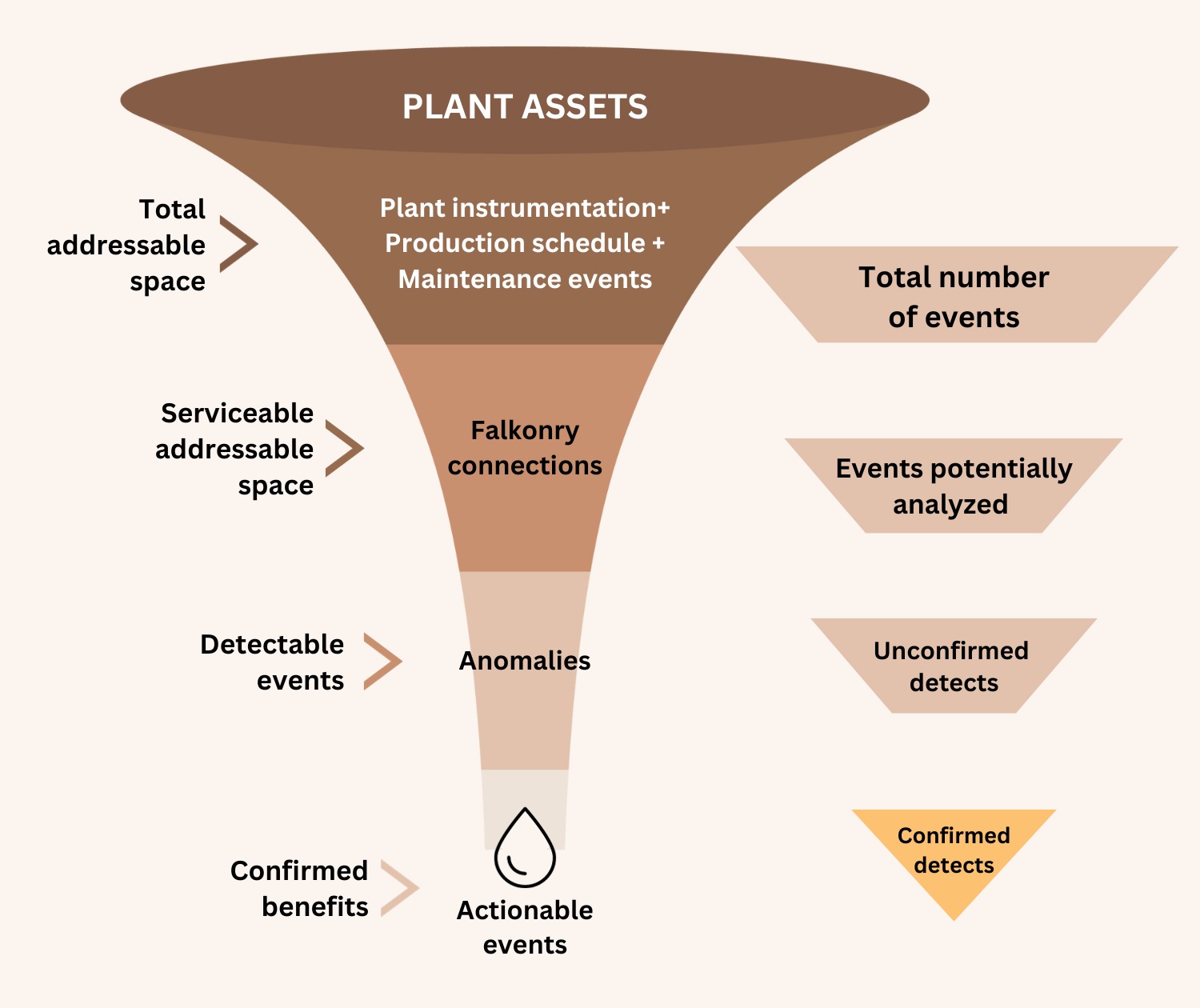

Imagine a manufacturing plant teeming with assets generating data streams comprising production schedules, maintenance plans, and plant events. This amalgamation forms the “total addressable space.” Within this vast data landscape, some events hold the key to improving operations. Using AI, a subset of this data undergoes analysis to transform into actionable events. The BDR is the ratio of these beneficial detections to the total count of pertinent events, making it a reliable metric for evaluating the economic viability of anomaly detection.

Unlocking Real-World Impact

A beneficial detection rate (BDR) is assessed over a range of assets over a short period of time such as a month. A high initial BDR such as 15% creates a business case that is financially viable. Moreover, when extended to a large production facility such as a steel plant, a 15% BDR can translate to an annual potential productivity improvement of $4 million. Conducting a study to establish the BDR is an activity many of our customers have been going through. This helps organizations gain a clear window into the results of their AI adoption decisions, providing valuable insights to executives.

Building Trust for Adoption

Combined with trust in the explanation for AI’s findings, a robust detection rate provides the necessary impetus for adoption. With beneficial detection of events that are worth hundreds of thousands of dollars and dozens of hours of human effort, our customers see payback opportunities within the first months of adopting Falkonry AI.

Our customers consistently emphasize that when Falkonry highlights an issue, they pay attention. Trust in the AI means operations teams act on the findings, whether instantaneously or in the long term by incorporating the insights into continuous improvement. Beneficial detection doesn’t only encompass acted-upon problems; it also includes detections that enhance future problem avoidance.

Proven Results

Our studies with existing customers and industry leaders underscore the significance of the beneficial detection rate in gauging impact, even when analyzing just a fraction of data or behavior. It introduces a pragmatic and actionable framework for measuring the success of anomaly detection efforts.

If you’d like to find out how well anomaly detection can work for your operations, let’s tailor a study for your data and set you on the path toward Smart operations.