Falkonry’s AI Cloud for IIoT with Litmus can get you Smart results

Key takeaways:

- Manufacturers need to use AI-enabled operational optimization to boost productivity amid a difficult talent landscape and increased operational complexity but it involves too much effort and demands an upfront investment to put IIoT data to work.

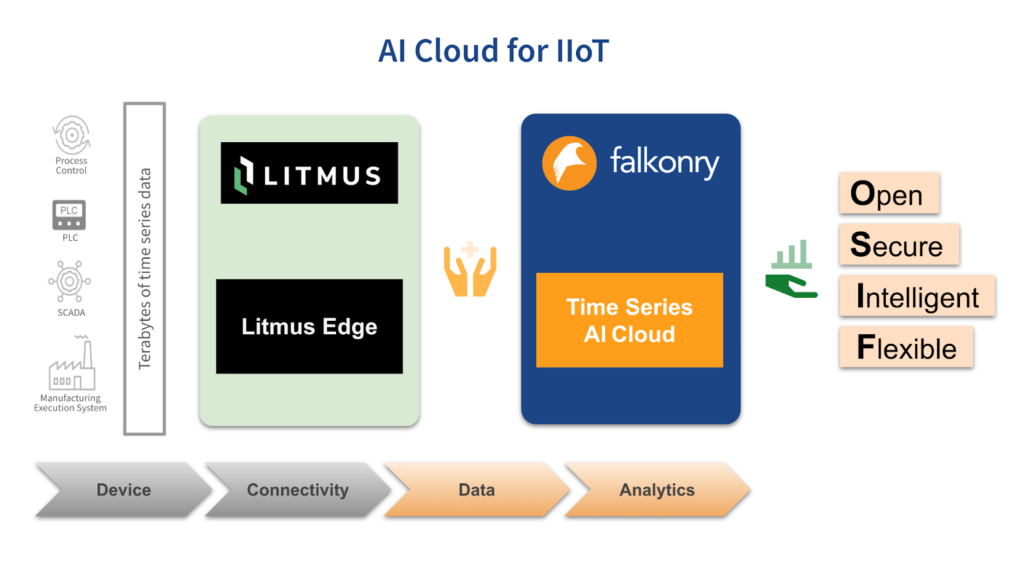

- Falkonry + Litmus is an innovative collaboration that seamlessly combines AI Cloud with a DataOps platform, putting IIoT data to work at scale.

- The joint solution aligns manufacturers towards a future where driving strategic decisions based on AI insights without the need to do any labeling, data science or software development, is a reality.

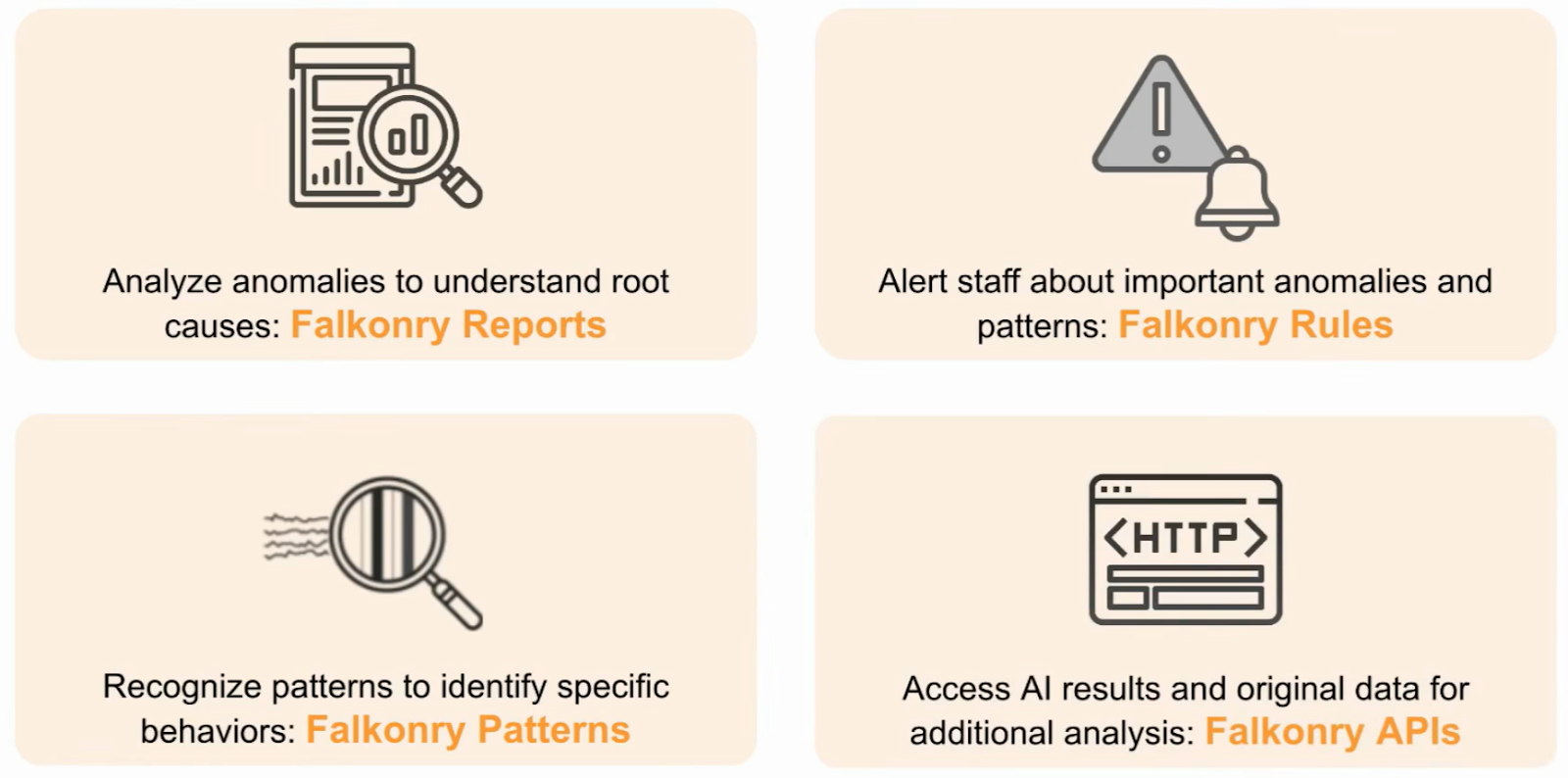

- This no code solution is open, secure and flexible, which enables digital teams to view AI insights, perform root cause analysis, alert staff about important events and recognize patterns to identify specific behaviors, so you are well on your way to get more from your IIoT data.

In an era where manufacturers strive to remain competitive by boosting productivity amid a difficult talent landscape and increased operational complexity, the need for AI-enabled operational optimization emerges as the only viable solution. The effective utilization of data is the only way to achieve the goal of higher productivity without large capex investments.

Manufacturers already know the potential that data holds. They also understand that the data itself is abundant. Hence, the challenge lies not in the availability of data, but in the translation of this vast resource into tangible value. A significant hurdle in industrial AI deployment has long been the complex IT groundwork required to establish seamless data connectivity between physical systems and analytics applications.

The challenges that hinder the realization of true operational potential include software development, data science effort, data labeling, and threshold setting. In simple terms, it takes too much work to put your IIoT data to work. Most current cloud-based IIoT offerings involve the complexity of navigating over half a dozen services and demand an upfront development cost and significant operations effort before you can even get started with AI.

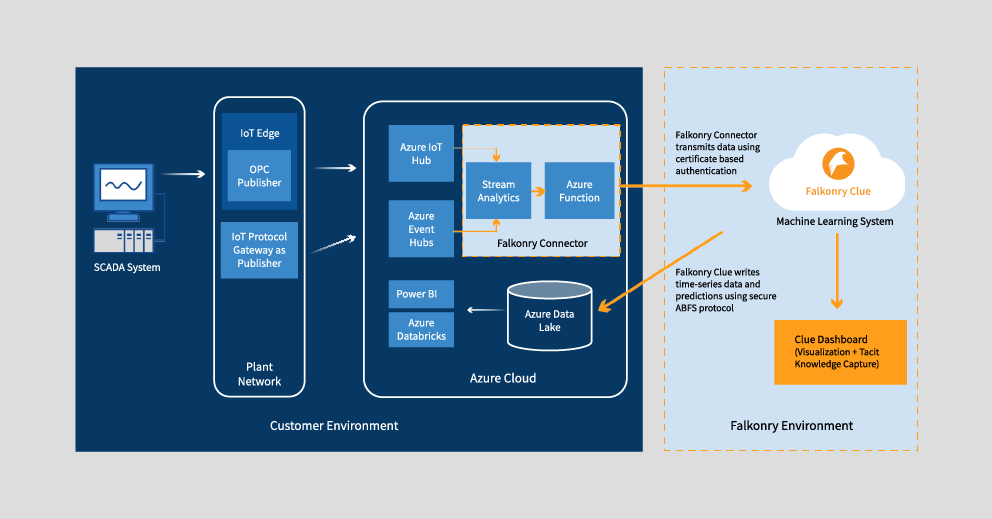

Hence, the need of the hour is a system that is open, secure, intelligent, and flexible, which is capable of overcoming the age-old IT/OT divide. Falkonry + Litmus, an innovative collaboration seamlessly combines Falkonry Time Series AI Cloud with Litmus Edge offering AI Cloud for IIoT.

Join us on a journey that demystifies the complexities of industrial AI deployment, as we showcase how Falkonry and Litmus work together to make your industrial data a usable asset. The joint solution aligns manufacturers towards a future where driving strategic decisions based on AI insights is a reality, fostering innovation, and ultimately ensuring unparalleled operational productivity in the face of evolving industry demands.

The need for an integrated solution

Effective utilization of data begins with two aspects. Seamless data connectivity and easy data integration. Both are extremely important in creating the foundation for optimizing industrial operations.

Data integration is fairly complex due to difficulties creeping in from fragmented data sources, data silos, and legacy systems leading to data gaps. Litmus Edge simplifies data integration, making data acquisition and accessibility seamless. It serves as a robust DataOps platform, extracting operational data from OT networks.

But what happens once the data is acquired? It needs to be channeled to a cloud application to extract value from it. This is where Falkonry comes in and does what it does best – efficiently organizing, analyzing and visualizing operational data to discover insights.

How does it work?

Step 1: Connecting Industrial Assets with Litmus Edge

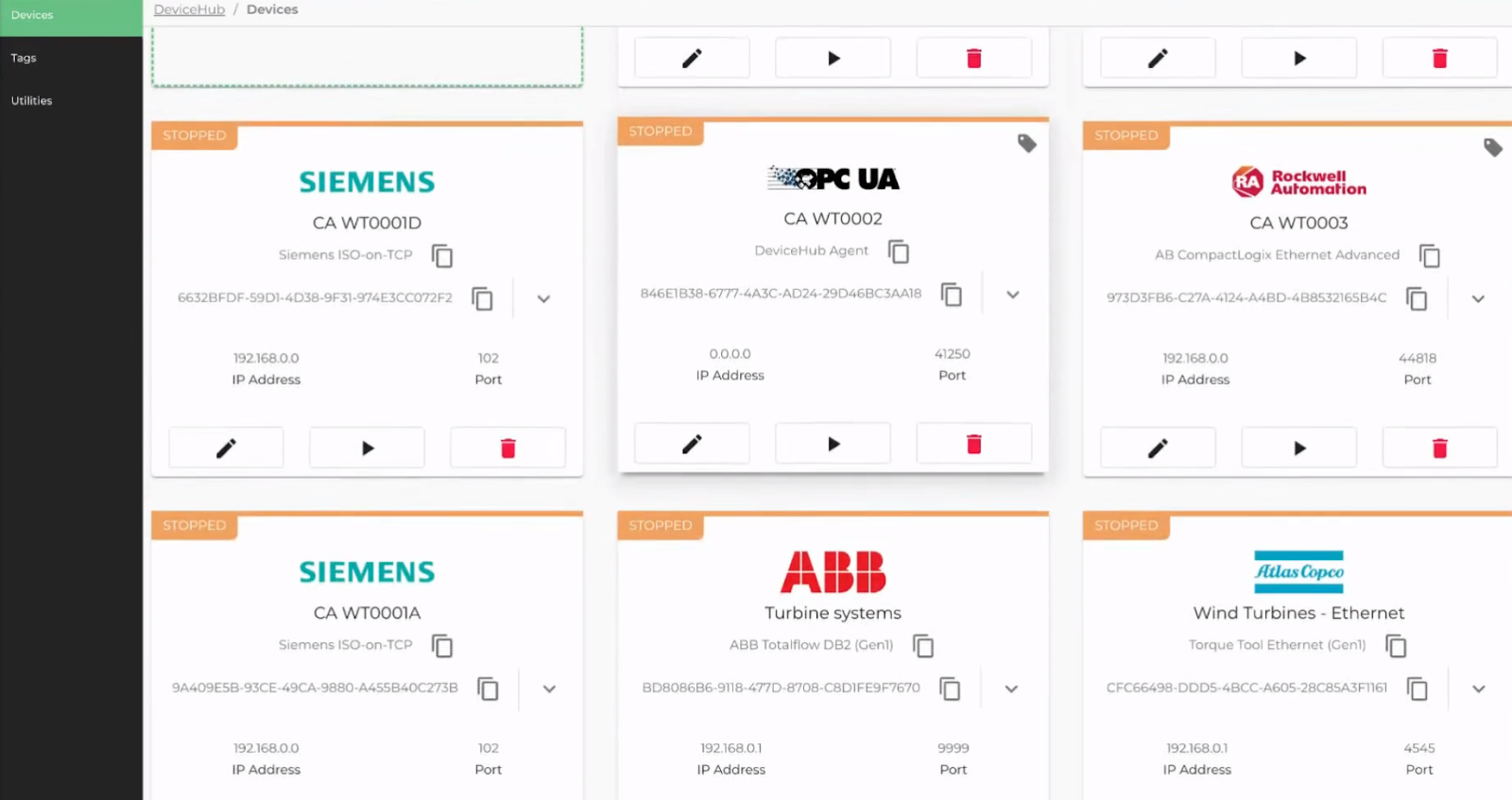

- The quality of AI is often determined by the data it accesses. Litmus has enabled the availability of instrumentation, telemetry, and automation data from a diverse range of devices and sources.

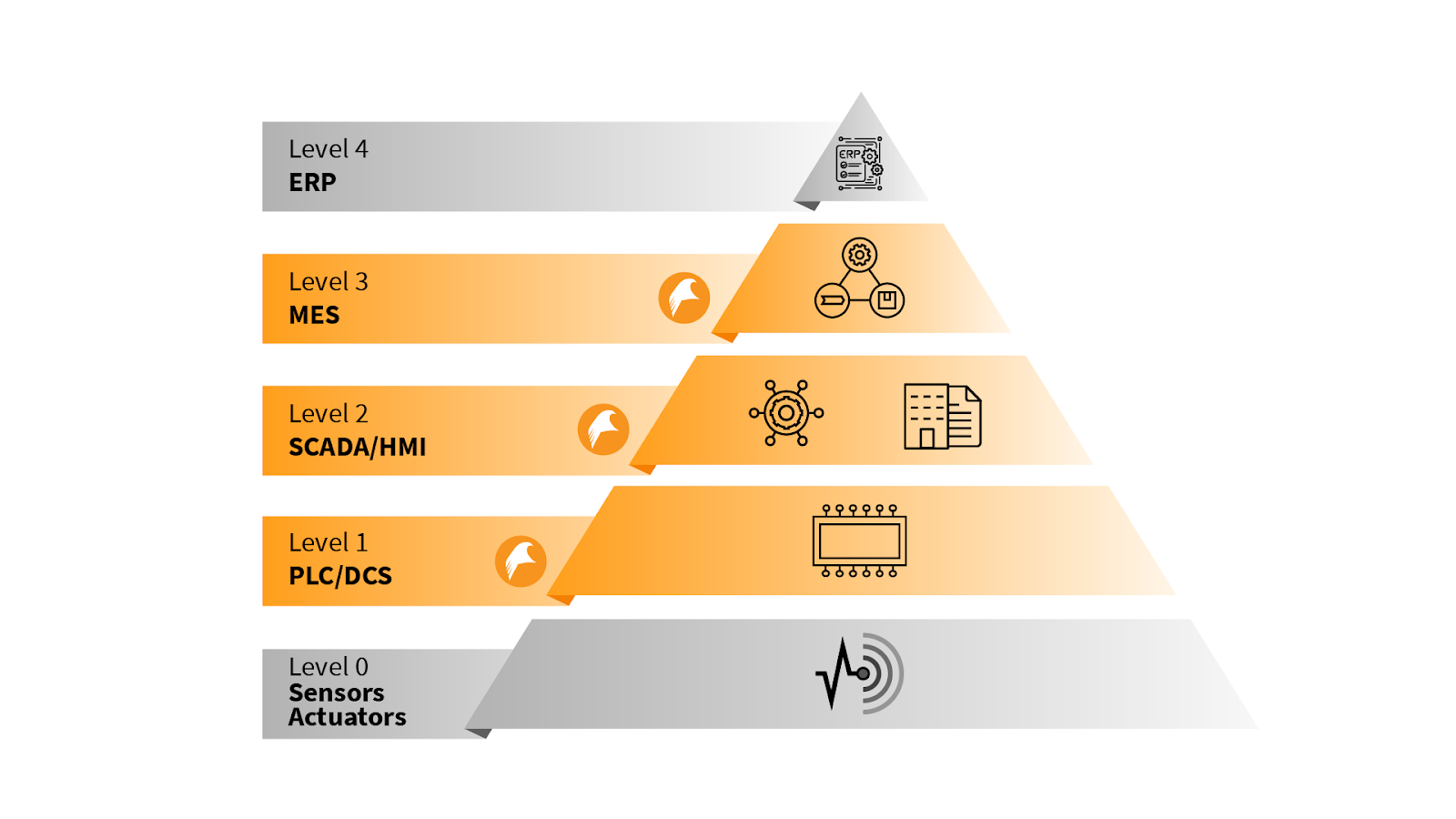

- The process begins with Litmus Edge connecting to a variety of industrial assets through off-the-shelf drivers. Litmus Edge supports connecting many types of industrial assets including PLC, DCS, SCADA, Historians etc, over protocols such as OPC-UA, BacNet, Modbus, CAN, and MQTT for several preconfigured industrial devices and their respective manufacturers. To make the process easier, Litmus can also scan the local network for connected devices.

Step 2: Capturing Data as Tags

- Litmus Edge captures real-time data as tags, which are the measurement sources commonly attached to PLCs.

- Litmus Edge organizes these tags in the form of digital twins and asset hierarchies to add contextual information to the data. This contextual information can include signal names, asset structures, and other groupings.

Step 3: Securely Transmitting Data to Falkonry AI Cloud

- After the industrial assets are connected to Litmus Edge, the real-time data collected as tags is transmitted to Falkonry AI Cloud over a secure connection. To facilitate this step, a connection is created in the AI Cloud to configure Litmus Edge with the security credentials generated by the Falkonry connection.

- Each tag produces a time series which is referred to in Falkonry as a signal. As data starts to flow from Litmus Edge to the AI Cloud, the signals contained in the data are discovered and become available for instant use. Both categorical and numeric data can be used in the AI Cloud.

- The signals are immediately stored and made available for review and visualization. To make it easy to locate and work with thousands of signals, the AI Cloud can help organize them by location or system hierarchy, or simply by importing the asset hierarchy from Litmus Edge. What is special about this is that you can have a quick and complete IIoT solution without writing any code.

Step 4: Putting the Data to work with Falkonry AI

- Falkonry AI Cloud automatically analyzes the IIoT data in real-time and detects anomalies on all the signals that have accumulated enough data. There is no need to set up thresholds, anomaly detection or to label the data.

- Each tag produces a time series which is referred to in Falkonry as a signal. As data starts to flow from Litmus Edge to the AI Cloud, the signals contained in the data are discovered and become available for instant use. Both categorical and numeric data can be used in the AI Cloud.

- Falkonry makes it easy to see anomalies in the context of the asset hierarchy. You can even contextualize these anomalies against reference data to know why anomalies may be happening. Why this is important is that anomalies help industrial teams avoid downtime and performance issues. This, in turn, allows for data-driven decision-making, leveraging the insights generated by Falkonry AI. The ability to put IIoT data to work without the need for labeling, data science, or software development, makes this solution very special and unique.

Benefits and advantages of the Falkonry + Litmus

✅ User-Friendly Integration: No Coding Required

- As a self-served solution, it eliminates the need for customers to write integration code or scripts.

✅ Effortless Transition from Data to Action

- Move from factory instrumentation to an intelligent anomaly detection and reporting system effortlessly.

✅ Automated Analysis

- Automatically initiates anomaly detection upon data transfer, optimizing operations without manual intervention.

✅ Event Recording Capabilities

- The system automatically scores data for anomalies, including bad sensors, drift, and equipment health. Persistent and severe anomalies are automatically recorded for further analysis.

✅ Centralized Cloud Management.

- Manage data centrally from a cloud-based interface, allowing easy access and collaboration.

✅ Flexible Visualization

- Visualize and compare data from any time period, providing a flexible and comprehensive analytical view.

✅ Real-time Tracking

- Data flows are continuously tracked for network interruptions and logical disruptions such as name or channel changes.

✅ Live Monitoring of Actionable Events

- The severe and persistent anomalies discovered by Falkonry are tracked as actionable events for live monitoring of the assets.

A glimpse into what’s possible

You can do so much more with data. Using the Falkonry Time Series AI Cloud, you can understand the root causes of anomalies, alert staff about important anomalies, and recognize patterns to identify specific behaviors. You can even access AI results and the signal data via ReST APIs, leading to a number of imaginative applications in areas such as safety, emissions, quality and work optimization.

In the future, you will be able to get a unified IIoT architecture through Falkonry + Litmus UNS solution that will make it easy for you to manage data flows and metadata flows between Litmus and Falkonry.

Unlike many IIoT offerings that grapple with a narrow focus on individual functions and lack of scalable intelligence, the Falkonry + Litmus solution breaks free from the norm. By seamlessly overcoming integration difficulties, labor-intensive ML projects, and the pitfalls of fragmentation, it provides a unique pathway to get your own AI Cloud for IIoT without burdening your IT teams. Why you will like it is that you only pay for what you use and the AI Cloud keeps track of how much you are using. With Falkonry + Litmus, you can now combine your data ops with an AI Cloud so you are well on your way to get more from your IIoT data.