Advance your knowledge horizon with AI-based anomaly detection

Key takeaways:

- Despite best efforts, conventional alarming misses too many events of interest and produces operator overload

- Rule-based anomaly detection requires huge upfront effort to set up limits and high ongoing maintenance

- AI-based anomaly detection requires no set up and enables the discovery of valuable known and unknown operational issues

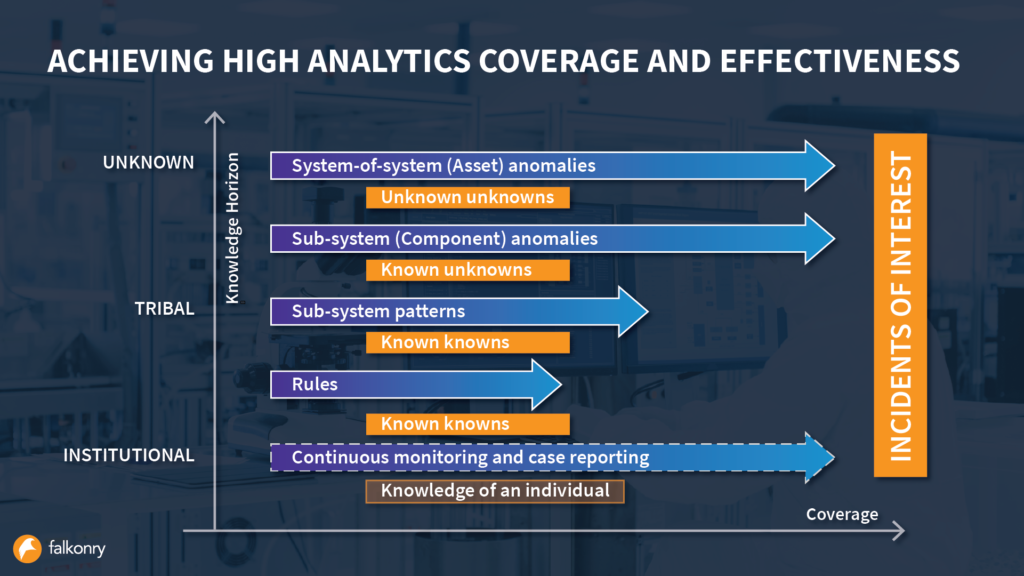

Industrial organizations are challenged with increasing complexity at the same time as they face acute shortages of skilled personnel. Traditional rule-based approaches rely heavily on previously discovered knowledge such as the occurrence of an incidence, its root cause analysis, and the engineering or vendor guidance on operating bands and control limits. Such approaches are difficult to sustain in many environments due to the constant need to tweak rules and an effort to minimize the burden on operators to review and respond to rule-based alarms. A major dilemma faced by these organizations is how to effectively increase the understanding of their operating environment both in a real-time sense and at an institutional level without staking all their available economic and human resources. Furthermore, these limitations of conventional methods have been apparent and a major motivator for Smart Manufacturing with an objective to improve operations while automating analysis to support decision-making.

There is sound reasoning behind the need to detect and eliminate anomalies as seen in the practice of statistical process control, six sigma continuous improvement, and reliability-centered maintenance. The reasoning is that anomalies are indicative of a lack of visibility/understanding and the associated safety and availability losses that arise from it. There is a clear and immediate need for automated anomaly detection that can be more data-driven and expands the organization’s knowledge base. In the process, such automated analysis starts to capture tribal knowledge and expose the unknown unknowns in your operations, thus increasing visibility and, therefore, reducing the possibility of surprises.

Going beyond rule-based approaches

Rules alone only scratch the surface when it comes to the potential insights that can remain undetected within your data. Another major challenge with rule-based control systems is the discovery of said rules. Coming up with rules is a labor-intensive and time-consuming process. Most often rules are established based on past events and engineering effort. Vendor inputs as well as experts are involved in establishing these rules because of the experience required to strike an acceptable balance between risk and pragmatic goals. Various first principles approaches such as simulation, governing laws, regressions, known correlations and mathematical transformations are options but they need a lot of manual engineering effort to carry out and as a result scale. How can AI help us spare the experts and allow us to go well past their knowledge?

The answer lies in AI methods that aim to learn the ordinary behaviors of a system so that it does not require supervision and the resulting prioritization of events can be managed from just two attributes of unusual behaviors – severity and persistence. AI methods should also surface the correlations that arise during unusual events. Finally, it should be easily possible to verify which similar behavior has previously been observed in order to establish the degree of unusualness of such behavior.

Accelerating the discovery of known unknowns

Rules essentially are a form of tribal knowledge, and one of the significant challenges organizations face is the institutionalization of tribal knowledge. Tribal knowledge, often held by experienced individuals, is invaluable for identifying and addressing known issues. Our work with ArcelorMittal/Nippon Steel Calvert serves as a compelling example of the AI’s ability to transform tribal knowledge into actionable insights. By translating a process engineer’s expertise in identifying specific shapes to classify strip breaks into a pattern detector, Falkonry enabled the automation of root cause analysis. By leveraging Falkonry’s pattern detection capabilities, organizations can utilize supervised learning to detect patterns and classify anomalies accurately. This supervised learning approach, focusing on subsystem patterns, highlights the immense potential of Falkonry AI to institutionalize and augment human expertise and knowledge.

The above example we saw of automating strip break classification by taking the learned experience of a process engineer and automating it with Falkonry’s pattern detection engine, was an instance of dealing with known unknowns. We know that we need to classify breaks but we do not know how they get classified. This is the first type of unknown which is when you know groups of parameters that need to be in sync but not exactly which type of behaviors will arise within those parameters. With these component-level anomalies, all you know is what normal operating behavior looks like and if that goes out of sync, it means there is likely a problem, but you don’t know what the problem is exactly.

Surfacing the unknowns with AI-based anomaly detection

The next level of anomalies is the unknown unknowns. These come out of left field and leave operation personnel blindsided as they represent unforeseen anomalies, faults, or hazards that organizations are unaware of but have the potential to significantly impact operations. The only way to discover these unknown unknowns is to look at a wider range of data. When tags are monitored and analyzed across the line, correlations can be found during anomalies that otherwise would not have been apparent. A good analogy to think about this is the human cardiovascular system. When trying to detect ischemia (or constriction in blood flow) it is not useful to test one blood vessel at a time. Instead, a contrast dye is injected that is able to light up all the points of blockage in the entire body allowing a specific, situational diagnosis from the observed correlations. With Falkonry you are able to similarly scan the entire line using anomaly detection lighting up all the so far unknown problem areas and finding parameters that are impacted by anomalous behavior that are showing signs of incipient damage. Incipient damage is where the system starts to move away from how it generally operates – and when it’s detected some variables will light up.

Usually in practice, we find that multiple points in a line will light up, not just one. Since you do not know in advance which combination might light up, this gives SMEs an opportunity to understand new causes and determine the most efficient corrective action.

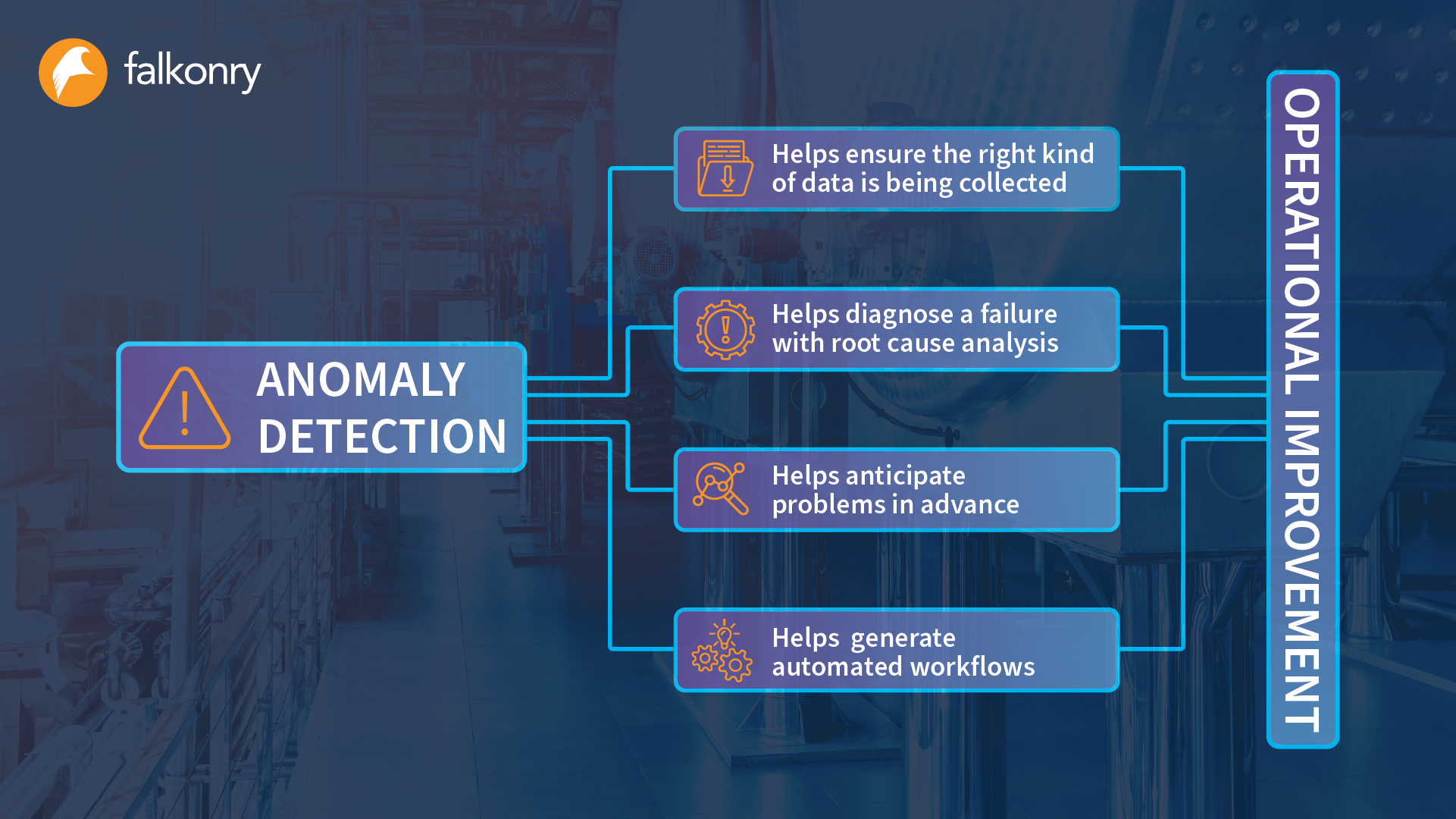

Beyond anomaly detection – from root cause analysis to action

With the adoption of anomaly detection, many organizations may worry about being overwhelmed by the volume of anomalies detected. The initial step is to prioritize and understand the unusual behaviors discovered by Falkonry’s perfect anomaly detection. Prioritization of the anomalies can be done based on the criticality of the asset itself and the severity and persistence of the anomalous behavior. Once anomalies have been prioritized, you can leverage Falkonry’s capabilities for root cause analysis, identifying the underlying drivers of the issue and accelerate the recovery process.

Once organizations have developed confidence in adopting AI-based anomaly detection, the next step is operationalizing and integrating anomaly detection into the plant’s existing processes so that responsible teams and individuals are notified to take necessary actions in a timely manner. When an undesired behavior is well understood through root cause analysis, notifications and downstream work orders can be automated. This holistic approach enables a comprehensive understanding of both known and unknown anomalies, paving the way for more effective decision-making and action.

What does it mean for you?

By transcending the constraints of conventional rule-based approaches, Falkonry’s advanced anomaly detection AI enables you to uncover hidden patterns, transform tribal knowledge into institutional wisdom, and navigate the complexities of known and unknown anomalies taking you one step closer to operational excellence. Falkonry can detect anomalies and unknown issues at a very large scale – at the level of an entire line – creating a very interesting data-driven benefit for smart manufacturing and smart operations. It provides a practical, new starting point and comprehensive roadmap to achieve superior analytics coverage with greater effectiveness for availability improvement.

To learn more about how AI-based anomaly detection can result in tangible operational improvements, click here.