Anomaly Detection

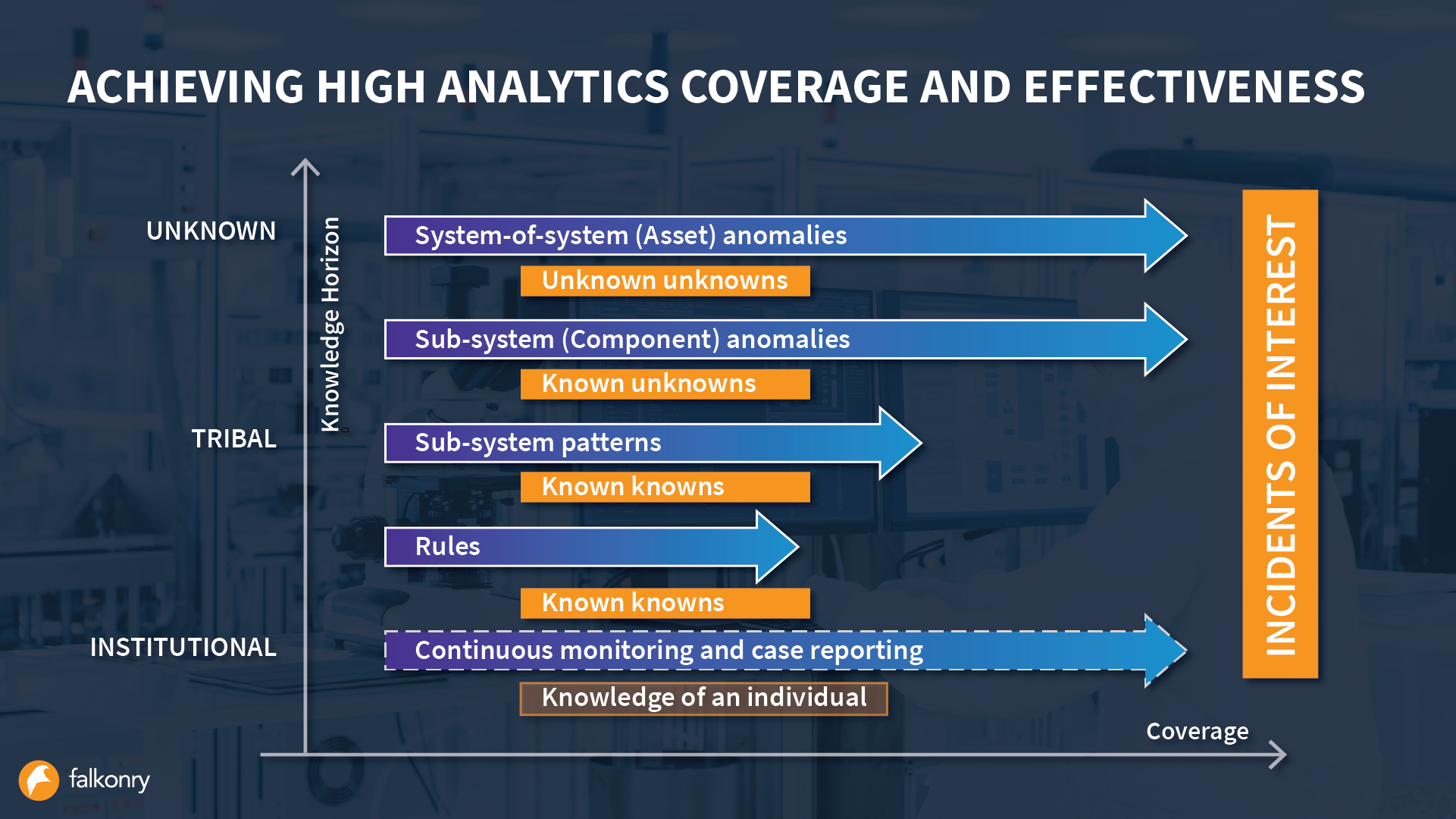

Anomaly Detection involves pinpointing atypical events or observations that distinctly deviate from the norm within a dataset. This approach is also referred to as outlier detection, aimed at identifying exceptional or novel occurrences that statistically diverge from the rest of the data points. Anomaly detection, as a technique, is commonly used to uncover suspicious occurrences in data that might indicate errors, defects, frauds, and other noteworthy events in the physical world.

What is Anomaly Detection?

The precise definition of an anomaly holds significant importance in defining anomaly detection. If we define an anomaly as behavior that strays from the usual, then the level of anomaly is determined by its variance from the norm. This concept is pivotal to discerning unusual behavior and promptly flagging it as an anomaly. It’s noteworthy that an anomaly doesn’t always signify undesirable behavior. Anomalies are data-centric and solely pertain to behavior that stands out as uncommon. The primary concern lies in determining whether the behavior is genuinely unusual. This process of unearthing unusual behaviors from datasets is known as anomaly detection.

What is Anomaly Detection in manufacturing?

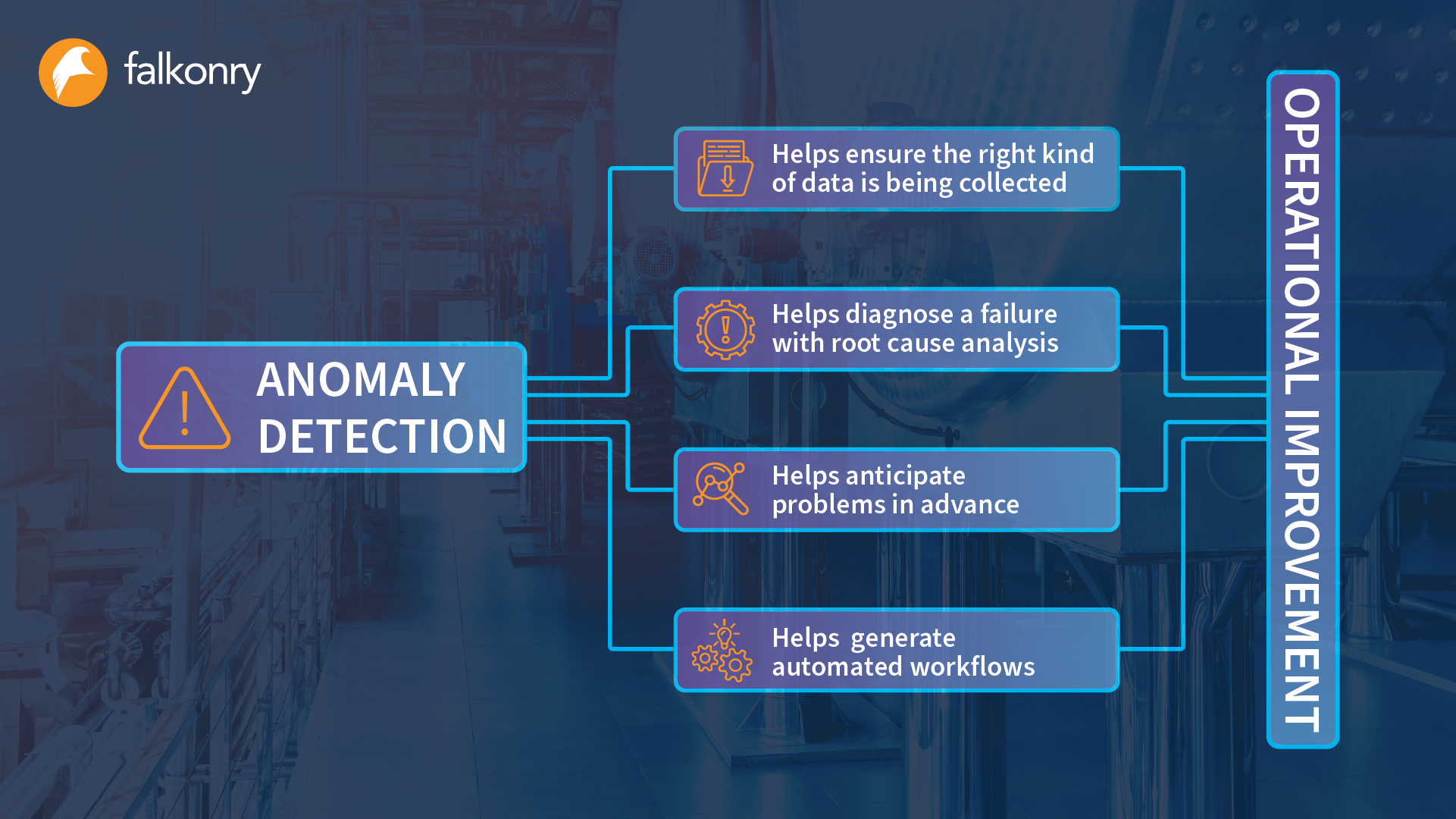

Particularly within the realms of manufacturing and industrial operations, such “anomalous” behavior often indicates operational issues that can lead to equipment downtime and quality deterioration. By employing this technique, operational personnel gain an understanding into the causes of process instability and equipment condition problems. This establishes anomaly detection as a prerequisite for real-time condition monitoring.

What is Anomaly Detection AI?

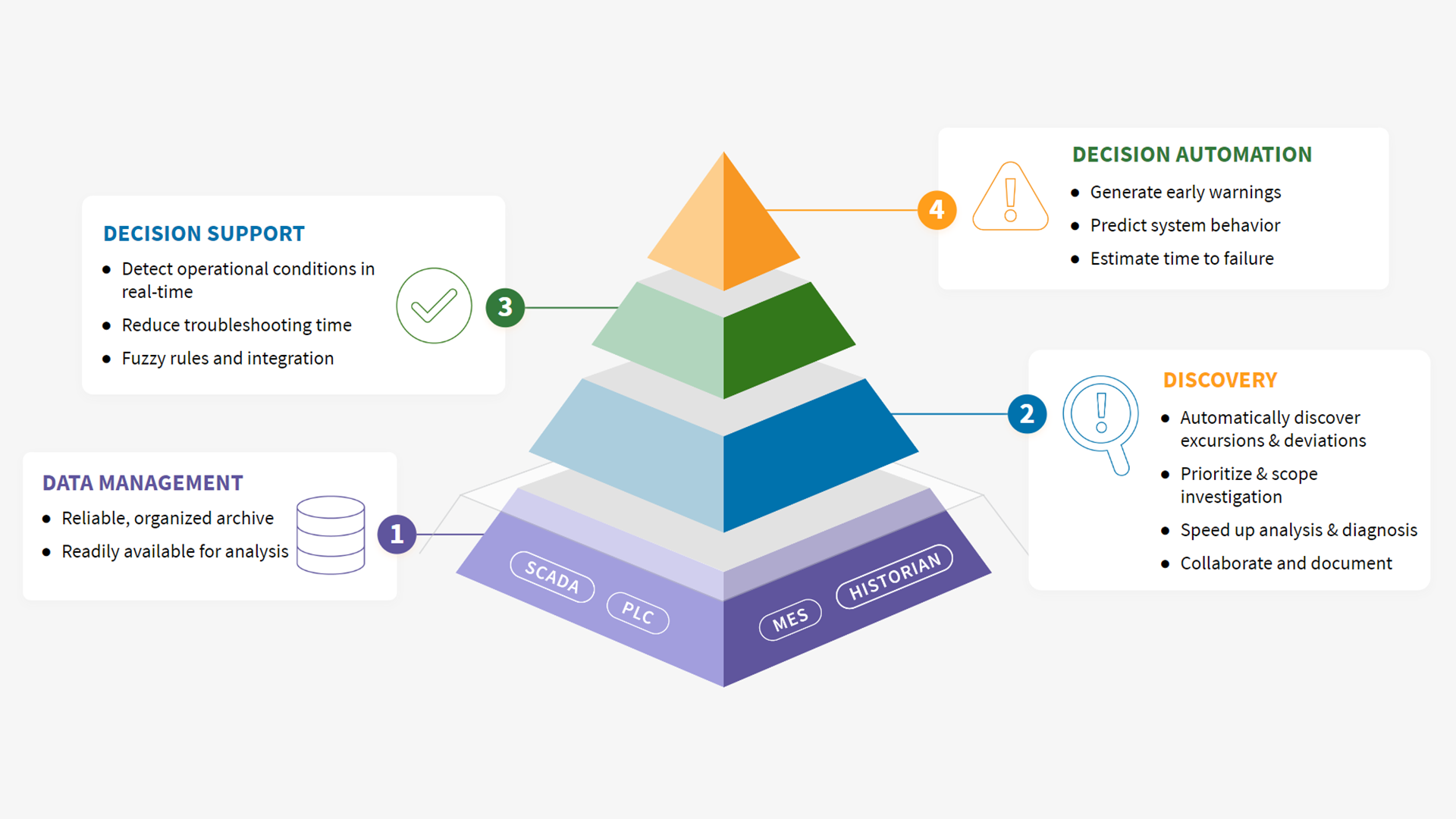

Anomaly Detection AI, in essence, is a predictive analytical technique that harnesses computing power to uncover unusual patterns or deviations in data. This type of AI proves invaluable in identifying early indicators of machine health deterioration and process irregularities within large and complex datasets or continuous data streams.

How does Anomaly Detection AI work?

Picture this: as data flows in, the AI learns what constitutes normal behavior and continuously forecasts what’s likely to happen next. As it constantly evaluates these predictions against reality, any inconsistencies or deviations that stand out as anomalies are promptly flagged. The technique allows observers to discern aberrations that warrant attention within the deluge of data being generated. This method involves the continuous prediction of anticipated outcomes (generative) and their subsequent comparison with actual results. When there’s a noticeable disparity between the predicted and observed values, the system identifies an anomaly – a departure from the expected norm.

What is the benefit of Anomaly Detection?

Think of Anomaly Detection as a focused lens that narrows down your field of interest. Imagine you’re seeking anomalies within a range of three standard deviations from the mean in a normal distribution. Statistically, about 99.95 percent of the data remains well within the expected behavior. By defining this level of “unusualness,” you can efficiently zero in on the 0.05 percent of data points that deviate significantly. This targeted approach empowers engineers to optimize their efforts and the value of their attention, leading to a substantial 99.95 percent increase in analysis efficiency compared to exhaustive methods that often overwhelm with unnecessary information.

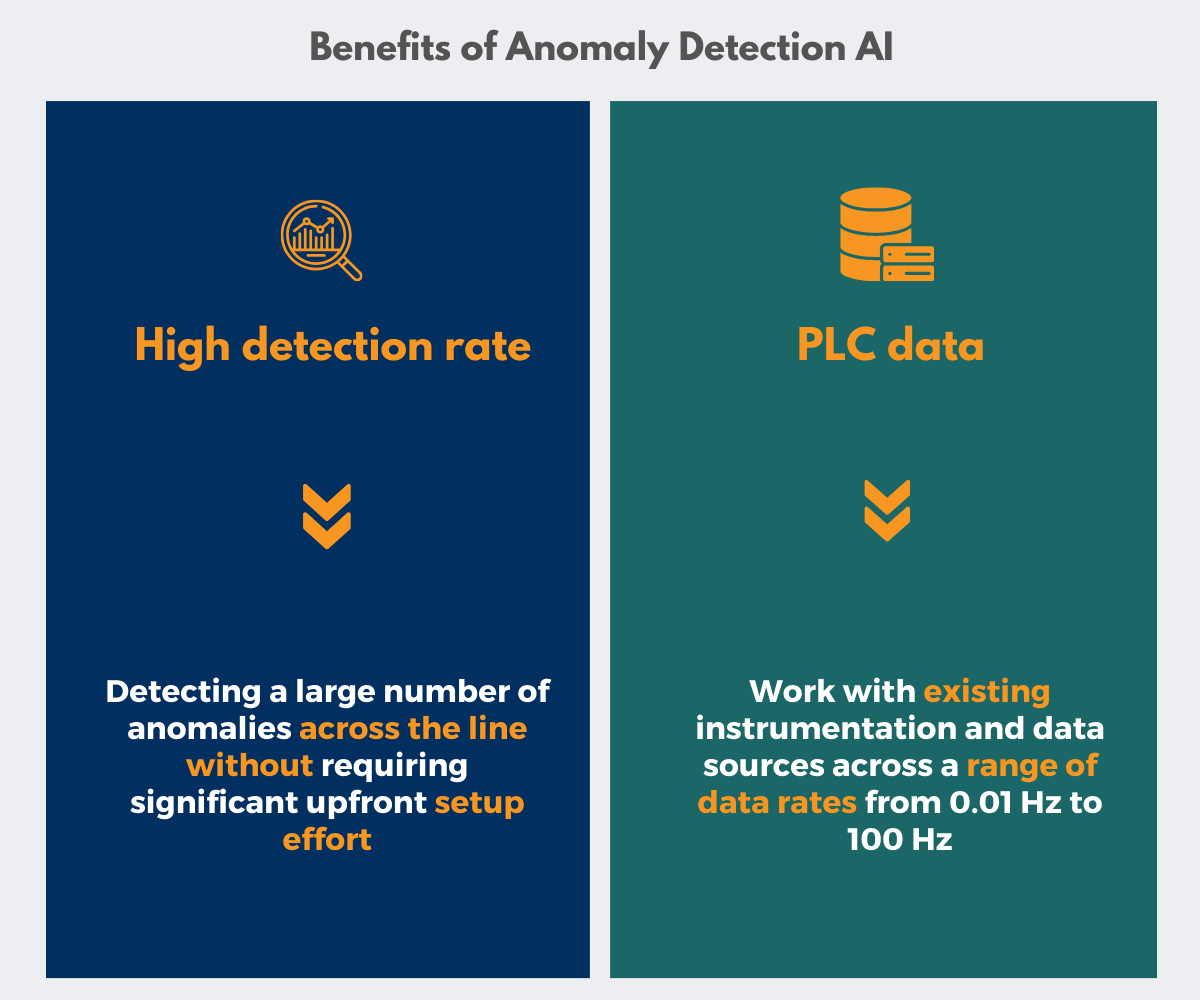

What is the benefit of anomaly detection AI?

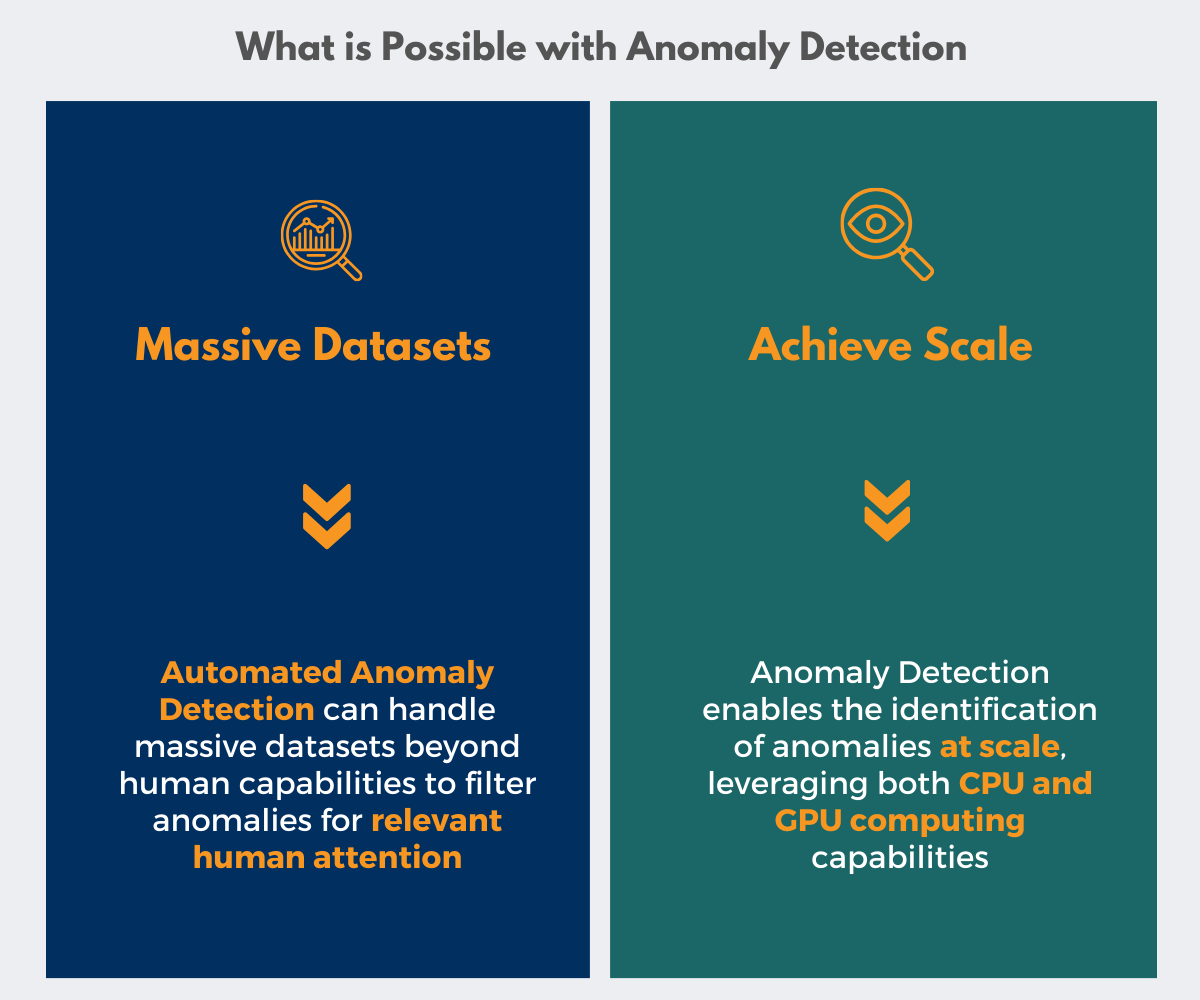

Anomaly Detection AI enables the identification of anomalies at scale, leveraging both CPU and GPU computing capabilities. The “AI” aspect surpasses conventional anomaly detection methods that rely on control bands (upper and lower limits), which can be challenging to set up and maintain. AI-enabled anomaly detection streamlines both the detection process and anomaly management, letting subject matter experts concentrate solely on interpreting results and implementing solutions.

Anomaly Detection AI can handle massive datasets beyond human capabilities to filter anomalies for relevant human attention. This allows manufacturing personnel to efficiently allocate their time towards troubleshooting, identifying root causes, and taking corrective actions by discerning deviations before they escalate into critical issues. In a nutshell, anomaly detection AI enhances the efficiency and effectiveness of maintenance and reliability professionals by focusing their efforts on what truly matters amidst a vast amount of data.

What is anomaly detection in time series?

Anomaly detection in time series data is the application of the principles of anomaly detection discussed above to a sequence of data points that are ordered over time. Time series data captures information at successive time intervals, making it particularly relevant for scenarios such as sensor readings, temperature/pressure fluctuations, and other dynamic processes. This specialized technique is employed by engineers, data scientists, analysts, and even AI software to identify abnormal or unexpected patterns. The core principle of anomaly detection in time series hinges on recognizing deviations from the established patterns or trends within the data.