Predictive Operational Excellence as a Competitive Team Sport

Key Takeaways:

- Changes in “the rules” can open the path to vastly better outcomes or spell disaster for organizations.

- To ensure your operations are on the winning side of such changes, think about them in the context of a competitive sports team: understand the strategic implications, develop new plays and train the players to succeed in the new world.

- Success comes from great teams of players supported by strong coaching and support staff.

There is more to a winning team than having a star player. More than having a legendary coach. There are a host of supporting characters in every professional organization which allow the front line, the people on the field, to put out their best and have it be effective. This is true in competitive sports. This is true in operations. It is particularly true when the old rules are being challenged and new strategies are emerging that change the way the game is played.

Sport provides a useful model for thinking about change in an organization. For example, in the earliest days of soccer, only lateral and backwards passing was allowed. This resulted in fewer goals during a game. In an attempt to speed up play and make the game more exciting, the offsides rules were changed in 1866 and multiple times in the early 1900s to allow more and more forward passing. These rule modifications resulted in big changes to offensive and defensive strategy which resulted in different tactics that the players needed to learn and use. Similarly, in basketball, the NBA added the 3pt shot in 1979. This change would eventually allow the Golden State Warriors to move from a 13th place team to a 1st team for 3 consecutive seasons. They not only changed their plays to take advantage of their skills in this area, having shown this was possible, the strategies and skills valued in basketball changed in general.

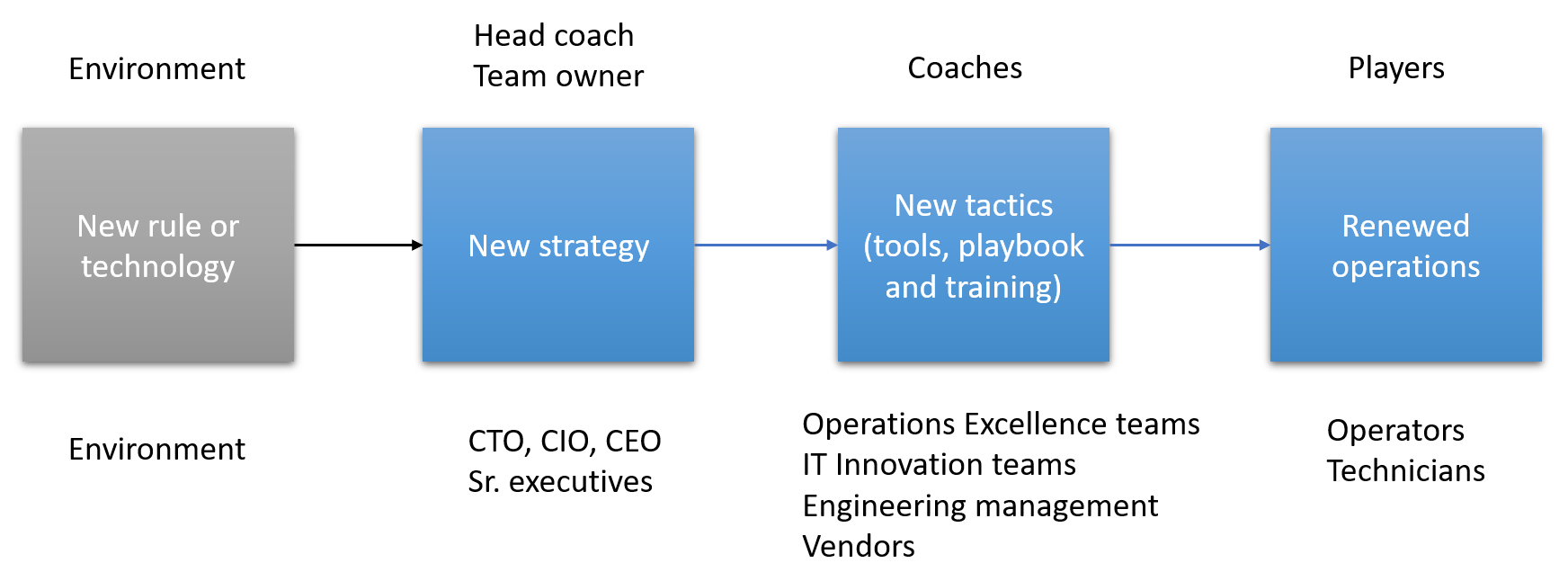

New rules or technology open the path to new strategies. New strategies demand new tactics, training and equipment to implement effectively. New tactics enable players to succeed on the new playing field. Generally speaking, this can be envisioned as shown in Figure 1 below.

Figure 1 – Changes in the environment of business or sport result in changes to strategy and tactics.

- The environment changes

- The team’s senior management assess the changes and develop a strategy addressing the new reality.

- The industrial “coaching staff,” including operations excellence teams, IT innovation teams, digital transformation owners, partnership development executives, engineering management and technology vendors, investigate and experiment. They find specific technology, integrations, business processes and training that will successfully implement the strategy.

- The new “playbook” along with the supporting equipment and training are put into place allowing the operators, the players on the field, to work at their best.

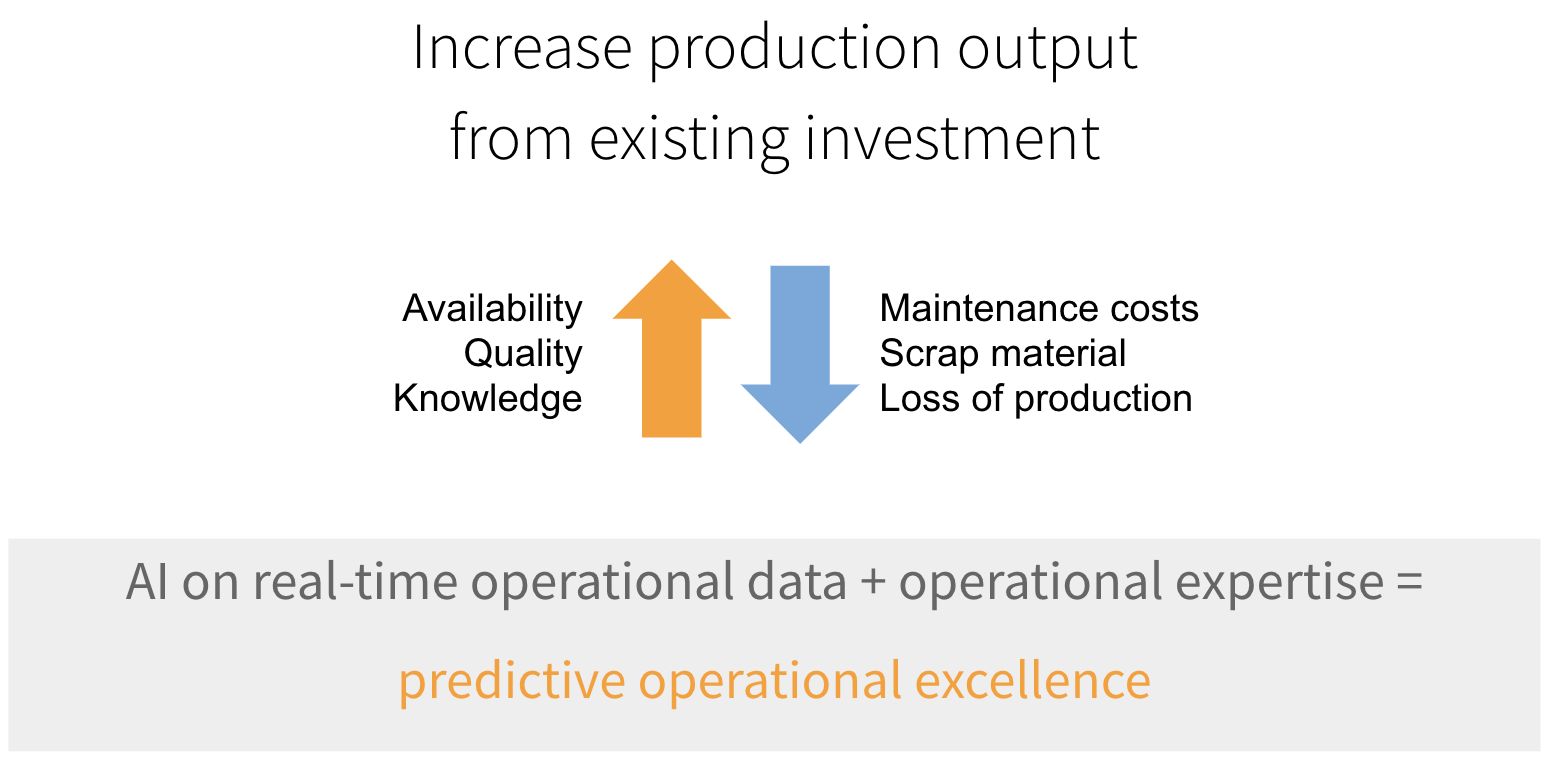

The IIoT: the convergence of sensing, storage, network, computing and software, presents a major change to the rules of manufacturing. These technologies make predictive operational excellence a possibility. That presents the same opportunities to production operations teams as the 3 point rule presented to the Warriors.

One example we saw of a company taking advantage of these changes was at a major steel manufacturer. The executive management team decided to address the challenge of increasing commoditization through a new strategy using software instead of through the traditional strategy of increased capital spending. The IT innovation team sought out a number of complementary technologies, including Falkonry, which addressed the need to increase plant capacity through availability and throughput improvements. They leveraged their in-house IT program management, cloud software development, and design skills to put together a next gen predictive operations solution. The innovation team worked closely with Falkonry to plan the team structure, solution architecture, and priorities. Finally, the “playbook” based on these new capabilities, was released to the operations teams who used it to work more effectively and efficiently, leveraging an Agile approach to operational excellence to achieve their goals.

Front line workers are motivated and capable, but it takes a team to win the game. Predictive operational excellence will happen when coaches (executive and staff) find the strategies, develop them into workable tactics with input from all levels and secure the necessary tools, training and compensation to carry out those tactics. As competitive sports teams have shown, change is an opportunity. Our contribution to the predictive production operations playbook is called Clue. Game on!