Introducing Falkonry Clue: A plug-and-play solution for predictive production operations

Key takeaways:

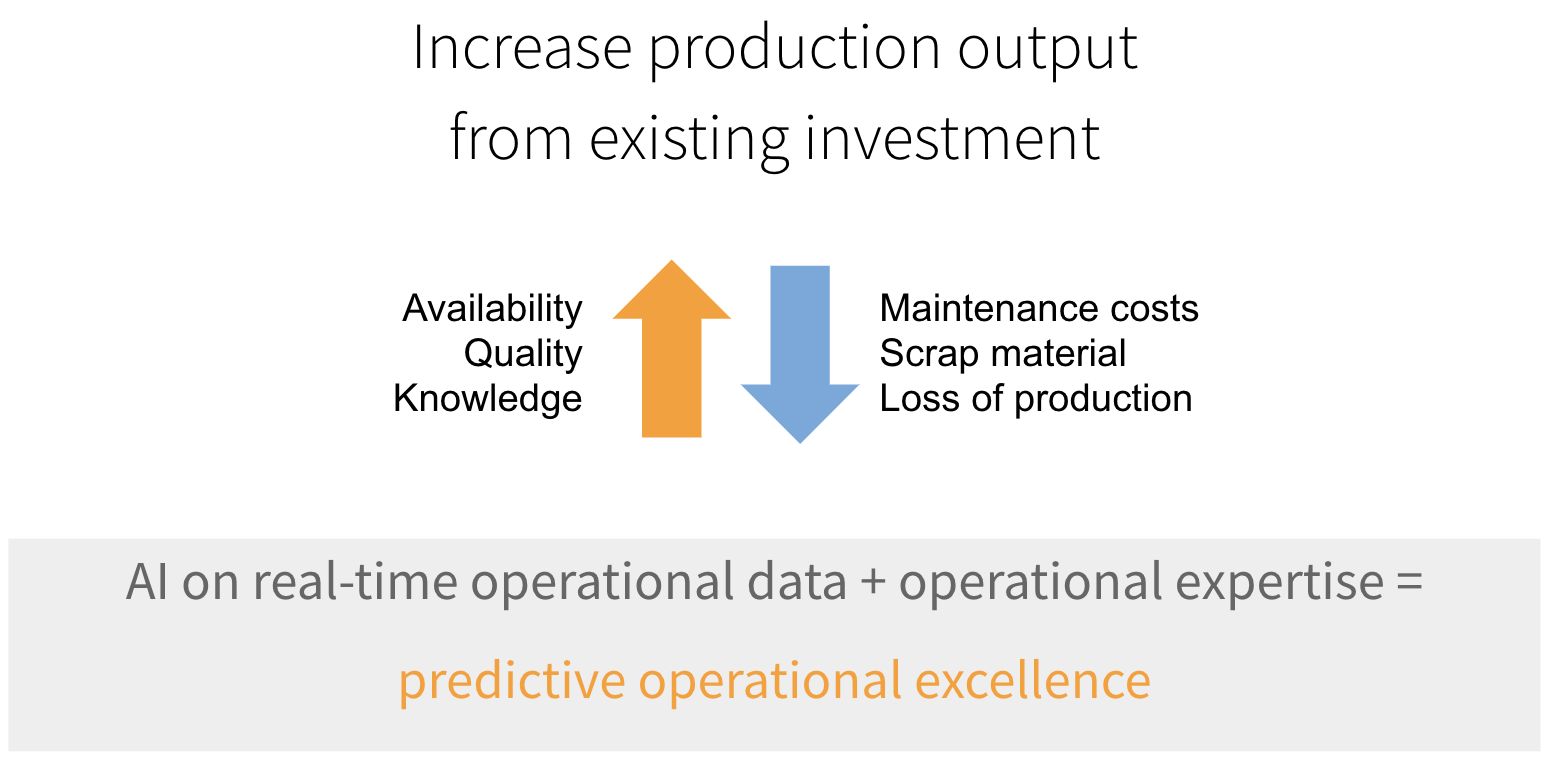

- Predictive production operations result in discovery of patterns in operational data to spot inefficiencies and avoid events before they impact business

- Falkonry Clue is a plug and play solution for predictive production operations that has already been evaluated in pharmaceutical, food & beverage, and electronics manufacturing

- Clue connects to factory automation systems or sensors and is used directly by operational practitioners without the need for software engineers or data scientists

We are excited to announce the newest member of the Falkonry product line – Clue. Clue is an intelligent, plug-and-play solution that automatically discovers potential inefficiencies and adverse events from real-time operational data and captures operational expertise for efficient reuse. Clue does not require historical data and can be easily connected to factory automation systems and sensors. Clue also does not require ongoing professional services or maintenance effort, which makes it possible to adopt at scale. This is because Clue was designed to be used by operations personnel without any need for software engineers or data scientists.

Figure 1. Clue connects with factory automation and sensing devices in the plant to provide a ready-to-use live dashboard for predictive production operations

Clue embodies the approach of predictive production operations and leverages operational data patterns. Clue is inspired from our experience with dozens of predictive operations customers across industry and government sectors. These customers have achieved significant results using the Operational AI-powered Falkonry LRS. As these customers developed confidence in data-driven methods they started to consider a future where these methods are integrated in every corner of operations and they have asked us to address two challenges crucial to adoption.

The first challenge is to further reduce the time-to-first-value. We have seen various high-profile industrial AI projects fail to deliver value due to a lack of historical sensor data and due to a lack of ground truth regarding the state of the system. We have also seen projects fail to deliver value quickly when they are too focused on building “the perfect model” and miss an ongoing opportunity to gain incremental operational benefit. With Clue, the process of discovery starts from the moment the operation is connected and continues forever.

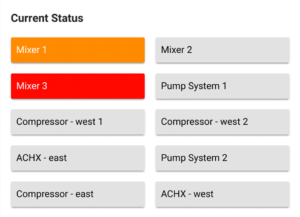

The second challenge is to reduce the burden on operations experts to receive value from their own operational data. With Clue, we have consolidated the experiences of our customers into a highly-automated process which does not require users to interact with machine learning tools at all, reducing both manual effort and the need to understand a whole new vocabulary. Clue accumulates knowledge using a conversational workflow where events with detected patterns are presented with relevant context and data. As users confirm the automatically discovered events, Clue builds an authoritative history of captured knowledge. The dashboard shown in Figure 2 provides the starting point for operational experts to impart their knowledge to Clue.

Clue enables plants to respond to dynamic business conditions while benefiting from their underutilized operational data and without the burden of hiring and training non-plant personnel. It learns quickly, captures important operational knowledge, and distributes that knowledge to the right people at the right time.

Figure 2. Clue dashboard showing the current state of an operation. Colored boxes indicate discovered events – red indicates a known behavior and orange indicates a novel behavior

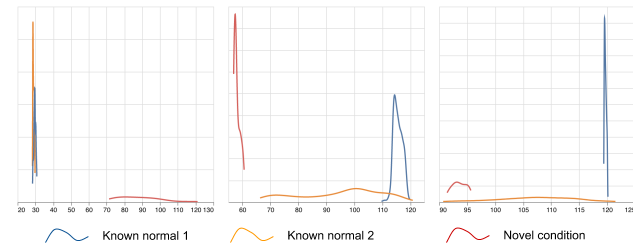

Clue compactly presents conditions and provides an easy way to compare them. A condition can still be visualized from its underlying pattern, i.e., the traces of its most important operational parameters. Root cause analysis of a condition takes into account traces and comparisons of parameters that are implicated in that condition. This condition comparison is represented visually in Clue as shown in Figure 3. This novel method of interpreting operational patterns is helping operational experts quickly diagnose the condition and record their know-how about causes and actions to the right people at the right time.

Figure 3. Diagnosing novel conditions by comparing values of important signals across conditions

Finally, a word about the availability of Clue: it is immediately available to customers and eliminates major barriers to receiving value through basic cloud connectivity. The data as well as findings are always under the customers’ control. Also, the price you pay covers cloud connectivity, storage and compute costs. Like Falkonry’s other subscription products, Falkonry Clue is also sold on an annual subscription, pay-as-you-deploy basis. All you need to do is connect your industrial automation systems such as SCADA, PLC, or DCS to Falkonry through our Edge Connector and a suitable interface such as OPC UA or MQTT. We are working with several companies that provide secure and low maintenance connectivity to get you started with Clue.

With Clue, now your plants, missions, and sites can finally start to see payback from their digital infrastructure and accelerate your operational digitalization. Clue provides operations excellence leaders a lever to lift the performance of their operations in a way that works across sites and product lines. And, last but not least, the cost of the Clue system is a lot less than even cloud connectivity technology, which means you can get so much more for the same IT dollar you are planning to spend. This is our vision of predictive operations excellence in a box.

Clue answers so many questions that hinder digitalization progress. We have some of the best operational digitization customers and they are very talented, organized, and perceptive about innovation that is disrupting their businesses. They love Falkonry for how we have accelerated their progress and have provided us some of the best feedback we can expect at this stage of the AI adoption curve. Now we are packaging all that feedback into a standard offering, which means you could have the advantage of their progress to accelerate your own initiatives. This is why we invite you to jump over a couple of maturity levels of your own operational digitalization by bringing in Clue into your operations.