Increasing production with zero marginal cost predictive analytics in manufacturing

Key Takeaways:

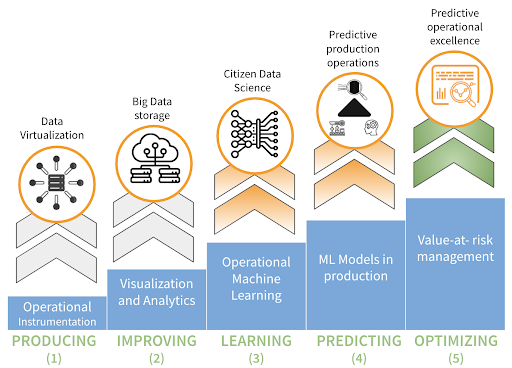

- As process control goals have moved from reactive to predictive, it has become progressively more expensive to roll out analytic solutions and bring them to scale. We are at a point where trying to extend the current methods has become cost prohibitive.

- A new approach is needed which reduces incremental cost per problem to near-zero by better utilizing existing resources

- The framework for such an approach is presented

It used to be easy.

Measure the outcome after production was done. If there were too many bad units, find the root cause and fix it. Of course that had a high cost in potential scrap. So…

It got harder.

Find sensors and intermediate measurements which could be taken during processing, track whether those measures varied from some average operating range. If they did, figure out why and fix it. Better, but the approach was still reactive resulting in some production loss. So…

It got even harder.

Big teams of data engineers and scientists were pulled together, given access to years of sensor, maintenance and log data and attached to teams of equipment experts. Months later, after significant data engineering, model development and validation, emerged a bespoke, single purpose model which could predict upcoming issues but which was detached from existing decision making workflows. Now this needed to be repeated for every equipment and process in the plant while also retrofitting the predictions into the plant’s standard operations. In the meantime, hopefully, business didn’t change so much that the work had to be repeated.

But that’s impractical.

Yes. Scaling up the high expertise, high touch methods typical of predictive analytics in manufacturing to dozens of problems around a single plant is not feasible from either a financial or schedule perspective. This is a dead end. However, we think that achieving the goal of widespread predictive analytics is possible but requires rethinking the previous approach.

What is practical?

Instead of asking how to scale the current approach, ask what must be true to achieve pervasive predictive analytics in manufacturing.

- The marginal investment per problem must be near-zero.

When the cost per solution is high, the value of solving the problem must be high. This makes starting projects difficult because, oftentimes, it isn’t clear which problems are valuable enough. It is also not clear how much of a solution can be obtained and what the value of a partial solution is.

Lower cost means less risk to experiment. More experiments mean more positive ROI applications can be found.

Achieving low cost per problem involves addressing a number of factors:

- People – The subject matter experts (SMEs) you have, the ones responsible for the equipment and processes, must be able to do the work within their work schedule. Hiring specifically to achieve scale is too expensive.

- Data collection – The SME has extensive knowledge that they can draw on about the process and equipment. The plant already produces copious data. Neither mining data from the labyrinth of databases nor installing new sensors should be necessary.

- Production deployment – Deploying a solution which plant operators can use and maintain must be low cost.

2. The approach must be able to support a wide range of use cases..

Not every project will succeed but if the cost per project is low, then it is possible to try a large number of them. By having diverse, empowered teams working in their areas of expertise, it is possible to increase the number of successes as long as the approach being used can accommodate that diversity without expensive customization.

An approach to predictive analytics in manufacturing is needed, then, that:

- Supports working on a plant’s current needs, in the context of its SME’s day-to-day job.

- Works with data from existing sensors and does not require extensive prep work.

- Integrates easily into existing decision making workflows or provides a complete, self-contained workflow.

- Supports trying many ideas in parallel.

- Supports a wide range of use cases without customization.

- Requires minimum maintenance even as the business evolves.

We’re building that system! Watch this space for more.