Getting Ready for Clue: Connecting Data Sources

Key Takeaways

- With a plug-and-play AI solution, such as Falkonry Clue, it is now possible to rapidly deploy AI into production.

- Connectivity between the plant and AI solutions whether operating in the Cloud or in the factory is now possible based on mature industry standards such as MQTT and OPC UA.

- Falkonry Cloud Connector, available with Falkonry Clue, provides rapid, lightweight connectivity to a variety of operational data sources inside plants, factories and in the field.

Clue uses data directly from the plant and this data needs to flow from the plant floor, where it is generated, to the cloud where alerts about novel and adverse behavior are produced. Falkonry bridges the OT world and the IT world through a highly portable, easy to install Cloud Connector.

The Cloud Connector works by collecting data directly from assets in the plant or by reading data from a process historian. It runs on a local gateway or virtual machine and securely, reliably, and efficiently moves data between plant and AI systems while managing the complexities of network protocols and data formats. This allows the operations experts to rapidly expand the use of Clue to solve operational problems without being constantly gated by progress on IT connectivity projects.

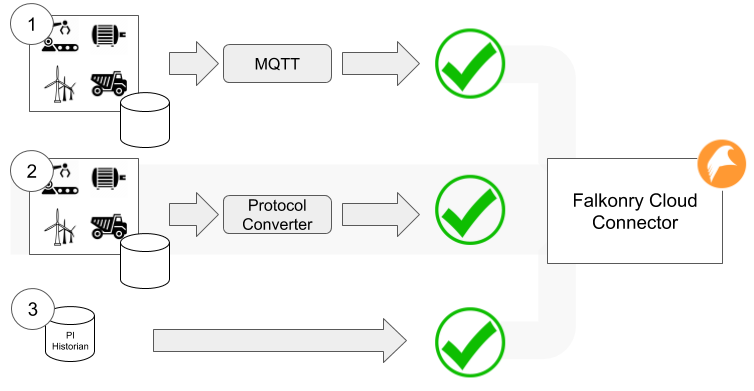

Common connectivity scenarios

Falkonry Clue is designed to receive data from PLCs, SCADA systems and sensor devices. Broadly speaking, there are three ways in which these data sources present themselves:

- Through an MQTT event bus as a stream of messages

- Over an OPC UA-based server that can provide up to date state information

- Via a Web service exposed from a historian such as OSIsoft PI System

This leads to the following scenarios which are supported by the Falkonry Cloud Connector as detailed in the new Falkonry whitepaper on Clue Connectivity and as shown in Figure 1.

- Direct connection to an MQTT enabled asset

- Connection to non-MQTT (e.g. OPC UA) enabled assets

- Direct connection to OSIsoft PI system

Direct MQTT connection is accomplished by configuring the MQTT clients within the plant to communicate with the Cloud Connector’s MQTT broker. This is the simplest configuration and the quickest way to connect data sources to Falkonry Clue.

Connections to non-MQTT enabled assets currently require a protocol converter which can bridge from the asset’s protocol (e.g. OPC UA) to MQTT. These converter products are commercially available from PTC and Inductive Automation.

Communication with OSIsoft’s PI Historian is accomplished using a PI System connector within the Falkonry Cloud Connector. This connector uses PI’s WebAPI to automatically read data from the historian and send it to Falkonry Clue.

For more details about these connection methods, including message formats and security, please see the Falkonry whitepaper on Clue Connectivity.

Falkonry has designed the Cloud Connector and configuration process to establish data connectivity as easily as possible. With just a few hours of help from the plant IT team, operations teams can start to receive early warnings about their production issues from Falkonry Clue.