Data Analytics: Ready for Success

Key Takeaways

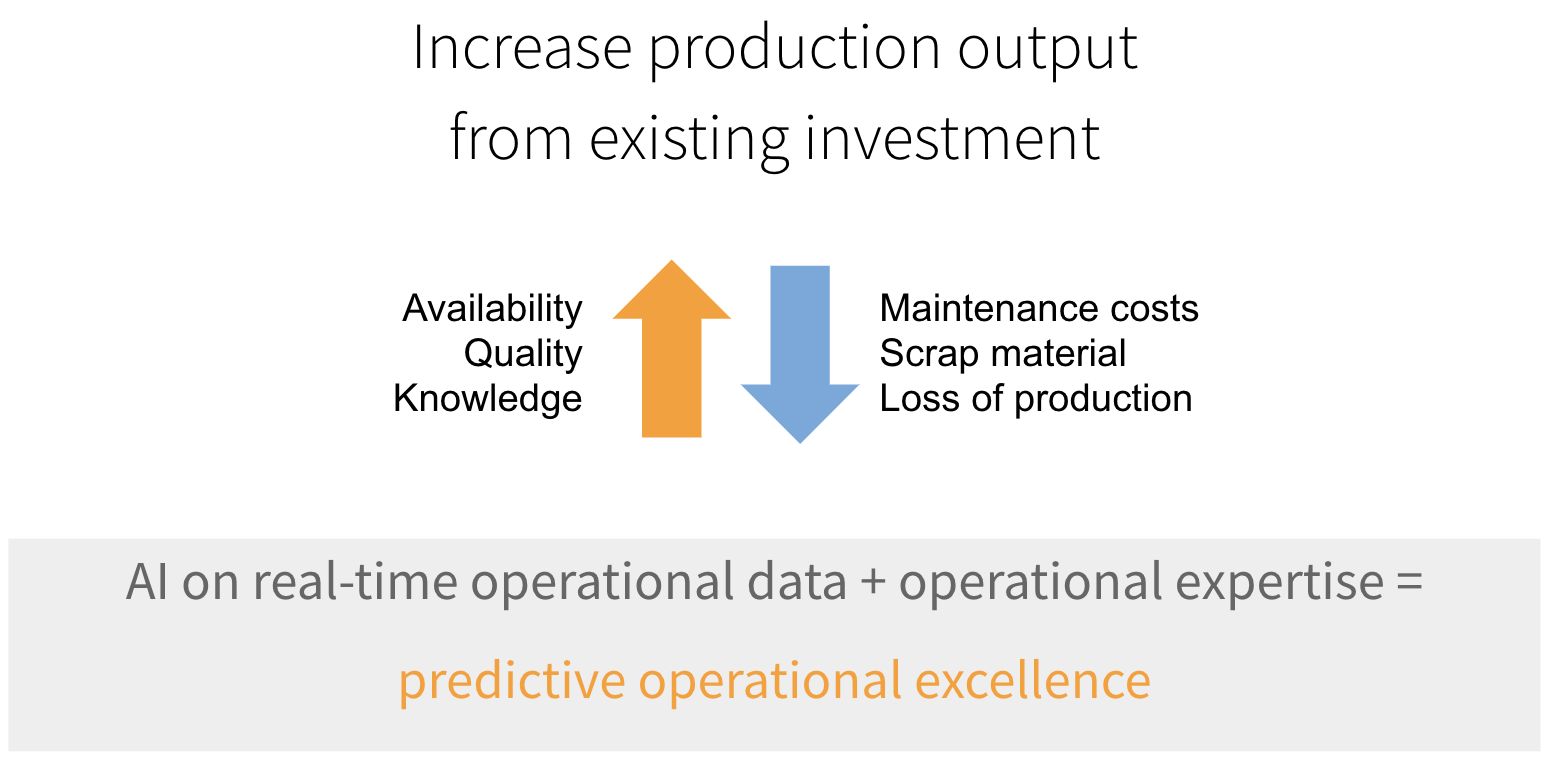

- There are potentially unlimited applications for data to improve operational excellence but there are a few guidelines which apply to all cases.

- Get top-down buy in and dedicated resources so that projects can last.

- Don’t be afraid to “fail” - iterate to learn what really works during design and after deployment.

- A software solution that makes achieving these goals easier is important for success.

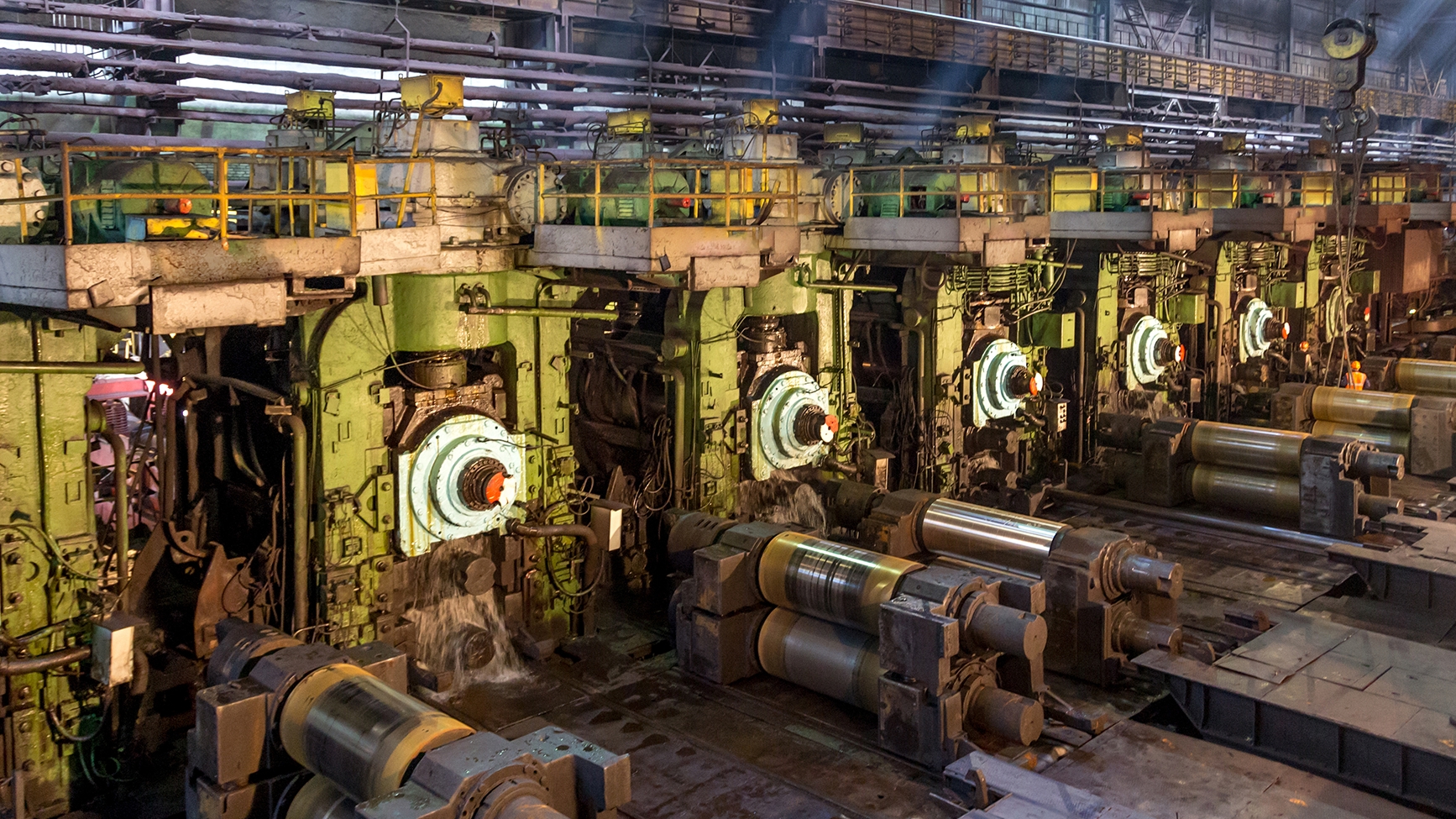

In the last 18 years, the scope and variety of projects I have seen is wide, ranging from pumps and piping to chemistry and process controls. However, in all of these there are constants; lessons that provide durable, on-target outcomes.

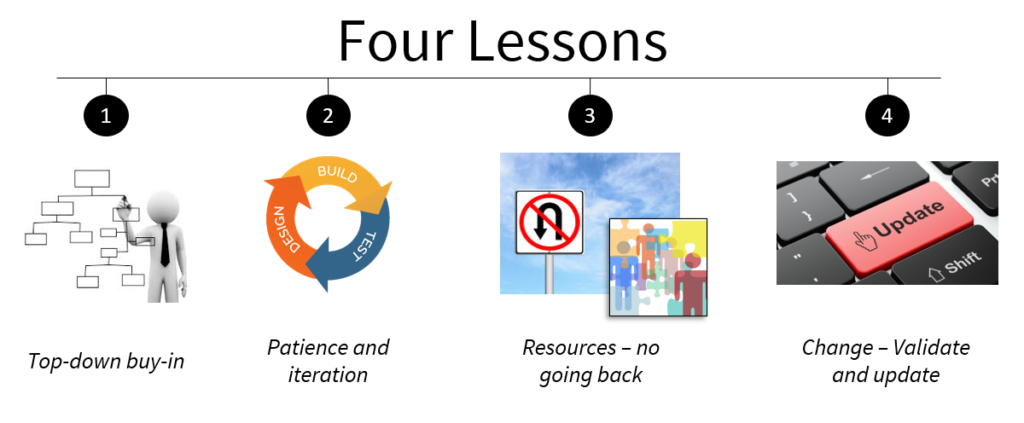

Lesson 1: Get top-down buy-in

For the industrial predictive analytics project you have built to last, many things are necessary. Key among those things is a commitment from the top that it will last. It is not enough that the solution technically works. It is not enough that the approach shows value. It is not even enough that operators and engineers have accepted the new way of working. Management actions, driven by misunderstanding or lack of alignment can easily undermine or reverse progress.

For example, at one client, front line operations faced a management challenge to reduce unplanned downtime. The operations team took it upon themselves to investigate and implement an analytics based solution which allowed the mill to avoid over $17M in capital expenditures while achieving a significant fraction of the downtime reduction goal. The solution was developed, operators trained and it was successfully deployed, delivering the target results. However, management was not part of the original solution. They had not internalized and committed to keeping it in place. Instead of holding the long term view which spawned the methodology, management emphasized a shorter term view: faster must be better. When run faster, most of the time the process was OK. Over time, this emphasis on speed caused the recommendations of the solution to be ignored. Hourly and daily production went up, but quarterly and annual production went back down to pre-change levels. The new approach was eventually dropped.

Top-down buy-in is critical to making a lasting change. Therefore it is important to have a solution which management can understand and see working, allowing them to rally and support early in the deployment process.

Lesson 2: Patience and iteration – It is OK to fail, fix and repeat

Very rarely does anything work as intended right out of the box. Factory control systems have commissioning tests, software has acceptance tests and new homes come with home warranties for a reason. This is doubly true for the kinds of difficult problems which operations teams face in managing their equipment and process: problems where the solution isn’t always clear and the best approach isn’t always obvious.

For example, in another client’s industrial predictive analytics project, the operations team was struggling to maintain reliable production rates. As an initial pass, the team looked at what plant operations usually label as the first stage of the process. However, the data analysis was inconclusive, presenting no clear direction on what was causing the upsets and limitations. In a second pass, the team broke the first stage of the process down into three areas: burner, wet process, and grinding. With the revised breakdown, data started to show the process issues as they traveled through each area. With this revised approach the operations team was able to determine the limiting factors and provide real time guidance on how to run the process to maximize utilization during upsets.

The ability to iterate and the patience to try again when the first attempt fails is necessary to achieving the desired goal. Therefore, we have found it important to have a solution which makes it easy for the operations team to adjust their approach or even their goals, until they arrive at an outcome which works.

Lesson 3: Dedicated resources – No going back…

Until the operators and engineers treat the new way as the default, it is not the way things will be done. The new approach can only be accepted when the working system has been integrated into day-to-day work. This integration requires resources: development resources to build the right tools, IT resources to ensure a responsive, reliable fit into the plant’s business processes and human resources to ensure that the necessary people are available and properly trained.

For example, just as a plant’s existing maintenance, engineering, and operations team have the skills to run the plant, a new data analytic tool needs dedicated resources with the skills to support it. In one industrial predictive analytics project, a client successfully rolled out capability that provided operators a target feed rate for the plant to maximize utilization. The project was complete and the engineers moved on to their next assignment. However, the plant provided no resources to maintain the new analytic tool and over the span of many months the process shifted due to feed material changes. As this happened, the tool became unreliable. Because of the unreliability and the inability to update the analytics, faith in the tool’s benefit wavered and the operations team stopped using it. By the time the engineers who implemented the original capability found out about the situation, they were working on other initiatives and did not have the time to make the necessary updates. With operators and management having seen the analytics failing for months, it was too late to stage a recovery.

Without adequate resourcing, even a technically good solution will fail. Having a solution which minimizes the breadth of skills required to keep it functioning so that it can be reliably operated within the scope of the operations team is a valuable plus towards this end.

Lesson 4: Dynamic systems change – Validate and update

Manufacturing operations are a dynamic environment. Equipment changes condition over time. Incoming raw materials change quality. Processes change as learning accumulates. Products change as market demand shifts or as forecasting technology changes. Because change is a constant, it is important to build model validation and updates into the solution. Understand the metrics so that it is possible to track reliability and accuracy of the analytics. Reserve time to stringently observe output and understand what it means. Stop the rollout process when issues are seen and resolve them so that hard-won buy-in is maintained. Finally, periodically follow-up with operators, foremen and management to ensure everything is still working as intended even as plant conditions evolve.

For example, a complex data analysis gave real time values that allowed operations to make process adjustments to maximize plant utilization without waiting for lab results. Unfortunately the result provided by data analysis was in a format that operators did not understand how to use well. Because of this, the results were not being effectively utilized by operations and confidence in the tool was dropping. Based on observation and discussion with the operators, the output of the data analysis was modified to provide set point values in a tons-per-hour target that they could run the process at. Reviewing how the system was being used to understand the gaps hindering success was critical to the industrial predictive analytics project.

You can’t run a marathon without working up to it. A solution which enables the operations team to regularly monitor their progress and make changes with minimal contribution from other teams is an important capability.

The number of potential applications for analytics software in industrial processes is probably unlimited. However the basic principles for creating a successful, lasting solution are few. Keep these tips in mind and choose the software which can help you:

- Find wins which top management can get behind and understand.

- Iterate quickly and effectively to help arrive at a good approach.

- Minimize external dependencies so that resourcing is easier to secure and preserve.

- Update your approach with minimal dependency on external groups to stay on top of changing processes and conditions.