Connecting Clue with SCADA Systems

Key takeaways:

- Integration risk poses a big challenge to organizations when implementing an analytical system for operational excellence

- Minimal effort is required to establish real-time data transmission from plants and machines to Falkonry Clue through SCADA and OPC middleware (data brokers)

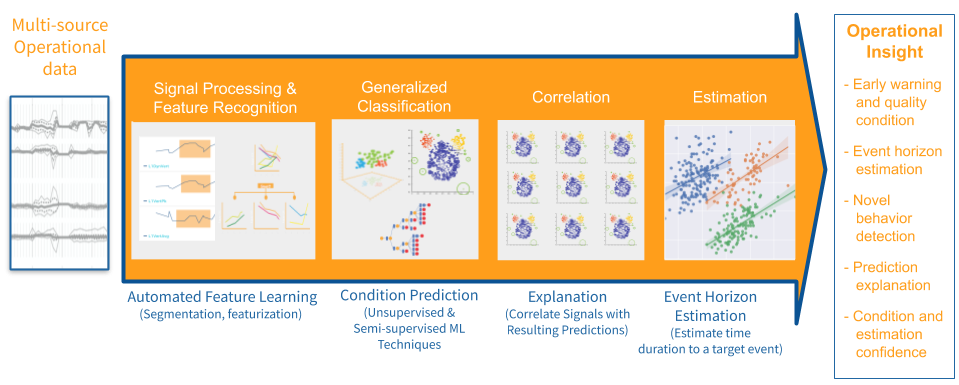

- Falkonry Clue enables ML-based continuous reliability improvement by exploiting real-time data without any data scientists

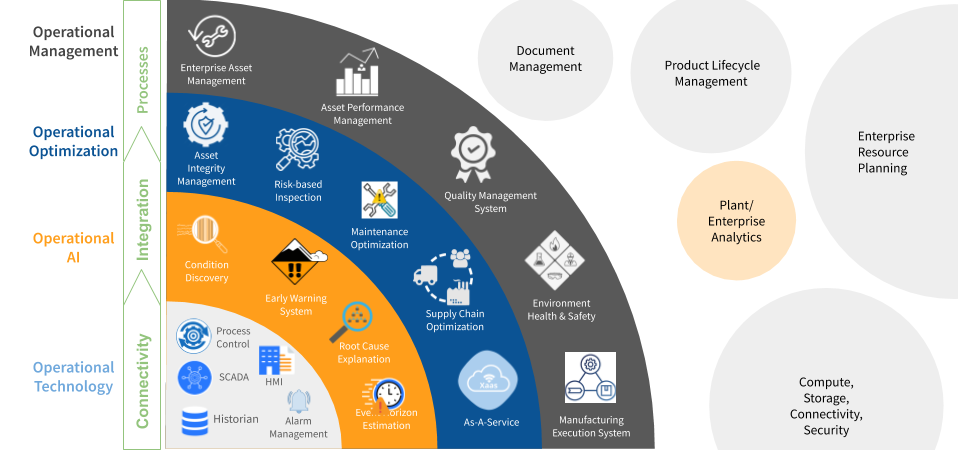

In the Industry 4.0 model, operational technology for supervisory control and data forms the basis for any operational excellence strategy. Most organizations have these systems in place with varying degrees of efficiency. The operational data collected is used in systems like SCADA, to control and maintain efficiency in processes, distribute data for smarter decisions and communicate system issues. The end goal of these systems for organizations across manufacturing and defense sectors is to use the data for enhanced decision making. The real challenge lies in utilizing the data generated for accurate analysis and thereby improving operational excellence.

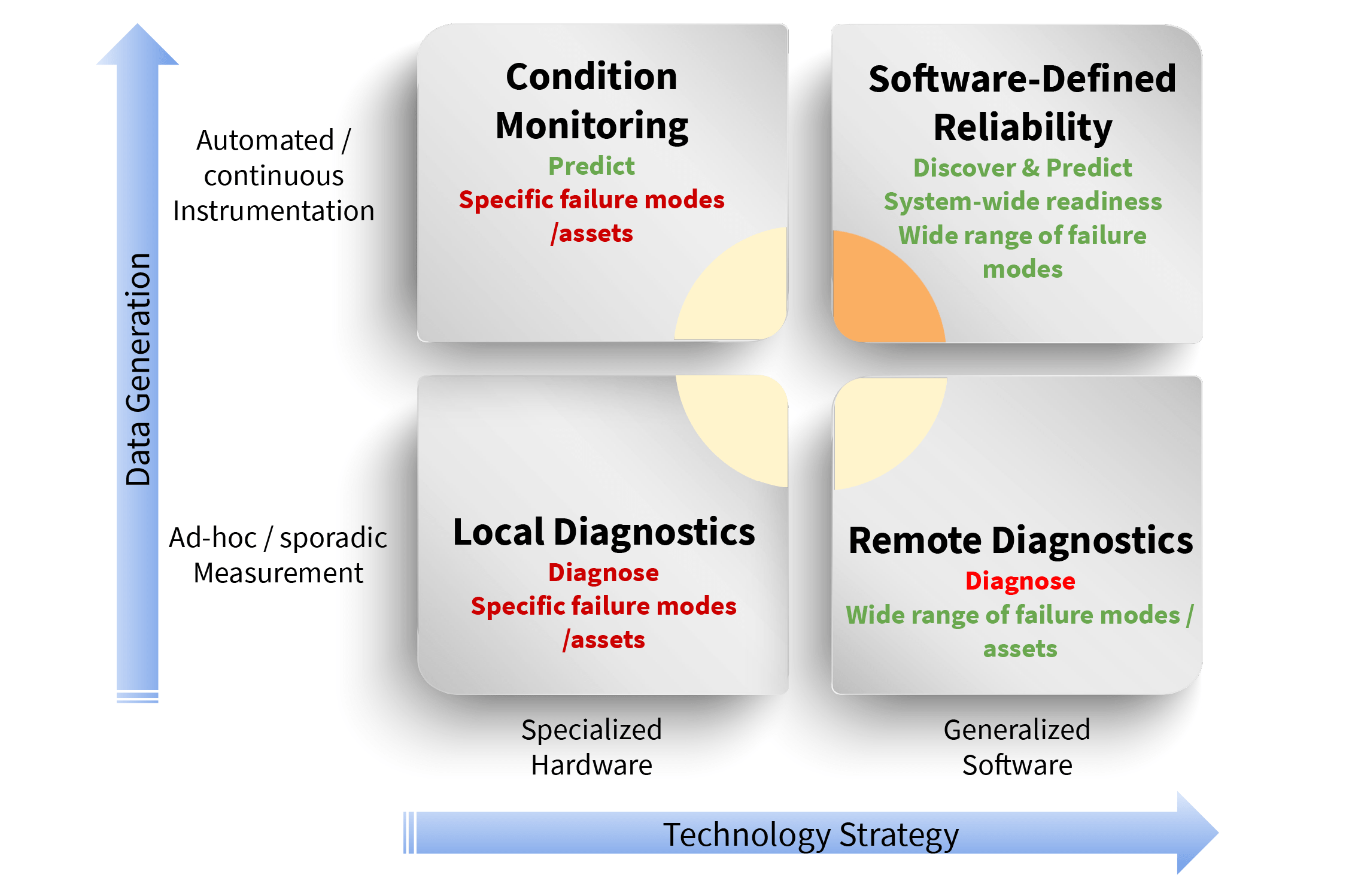

Integration and interoperability risk are considered as some of the biggest barriers to adoption for any Industry 4.0 technology. The challenge lies in being able to integrate data from various sources easily and seamlessly into the product and then using it to generate actionable insights. Data maturity and availability of the right set of data is also another concern. At times, even with systems in place, the right set of data is not always available or generated. Beyond all of the above, organizations also shy away from creating another set of data islands for the sole purpose of analysis. Apart from this and on the same lines is the implementation risk. Organizations are worried about picking the right use case, demonstrating a clear ROI and then being able to scale the system across processes and plants.

An effective Operational AI approach should be able to support data analysis straight out of the SCADA system, be able to start learning and provide meaningful results in a short time frame and is highly scalable. Falkonry Clue is a plug-and-play solution that improves system-wide reliability as its approach is highly scalable across plants and processes. It integrates easily with existing systems like SCADA and is also able to leverage historical data in historians/data lakes, if required. This allows Clue to provide meaningful insights in a short time frame as well use historical data, if available, to improve analytical output.

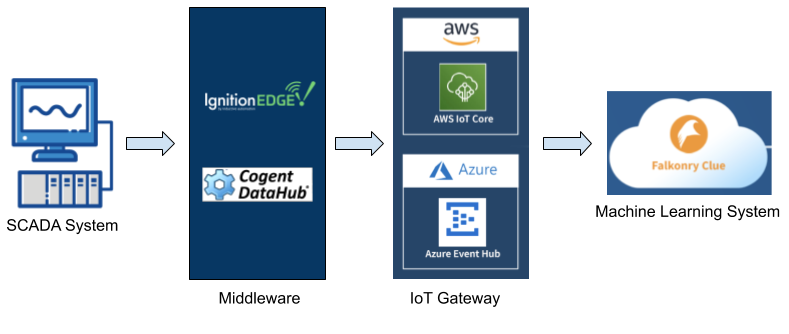

Middlewares like Kepware EX, Cogent Datahub IoT Gateway and Ignition Edge IIoT enable this kind of plug-and-play architecture.

A simple one-time setup involves configuring the middleware with the integration settings like IoT gateway host, port, certificate, client id and MQTT topic. Once configured, the middleware starts sending data to the IoT gateway which in turn is received by Falkonry Clue for continuous learning and real-time alerting.

Either when pulling data straight from the SCADA system or leveraging the historical data from the historian, the middleware interfaces with the existing system over OPC and Modbus communication and also connects with popular cloud IoT gateways (like AWS IoT core and Azure Event hub). Security risk in this transfer of data is also addressed by implementing a certificate-based authentication using the MQTT protocol. The data is sent to Falkonry Clue in real time for analysis and to produce a pattern-based summary of the operational data which drives predictive operational excellence.