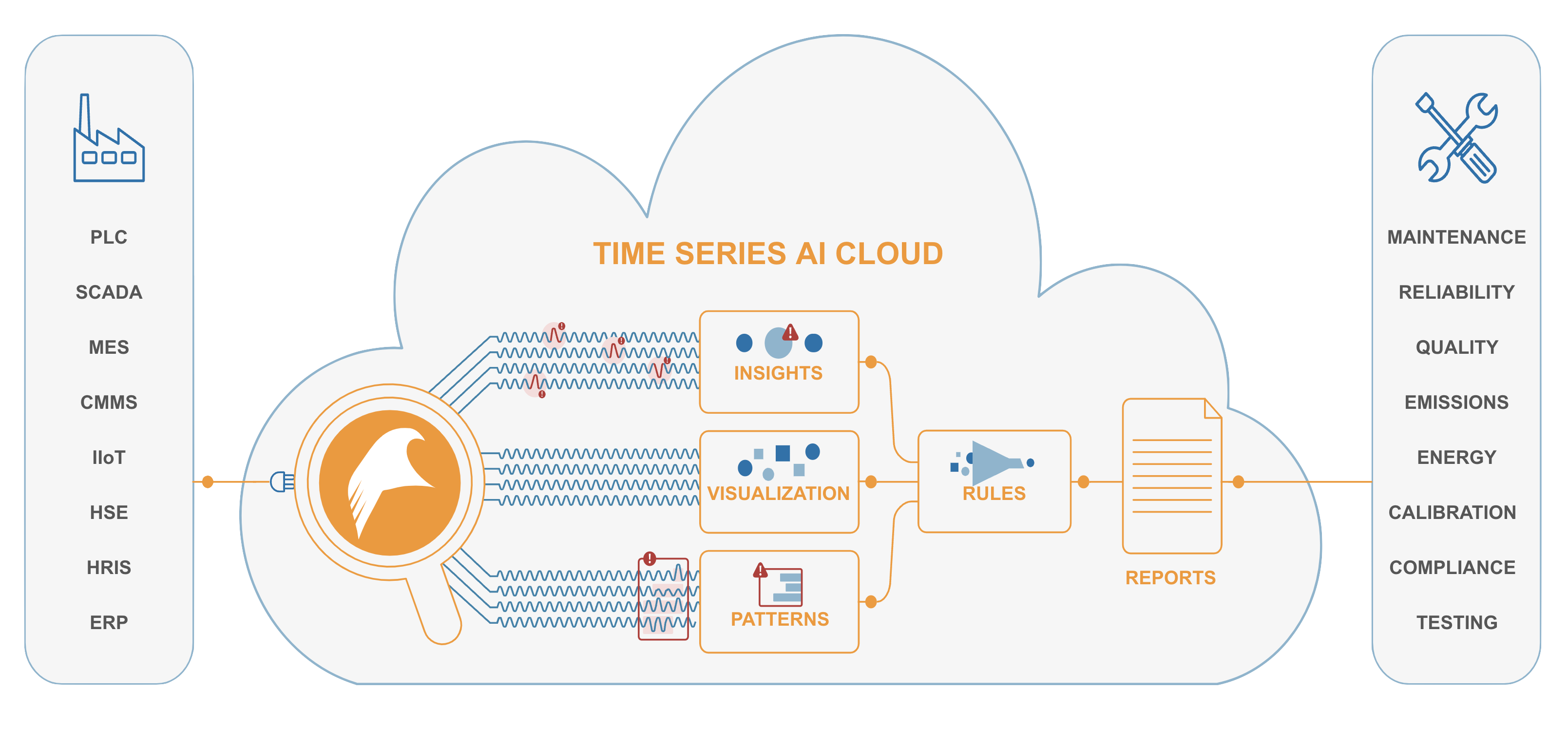

Turn your data into smart actions

Running a high-performance industrial facility shouldn't be a struggle, even with the overwhelming amount of data it produces. Automated AI analysis can help you review this data and bring to your attention excursions, faults and anomalies with explanations. Operations personnel can then use this distilled information to drive smarter actions for improving operations.

With time series AI it is possible to: