The Falkonry Story: From Inception to “Exit”

Key takeaways:

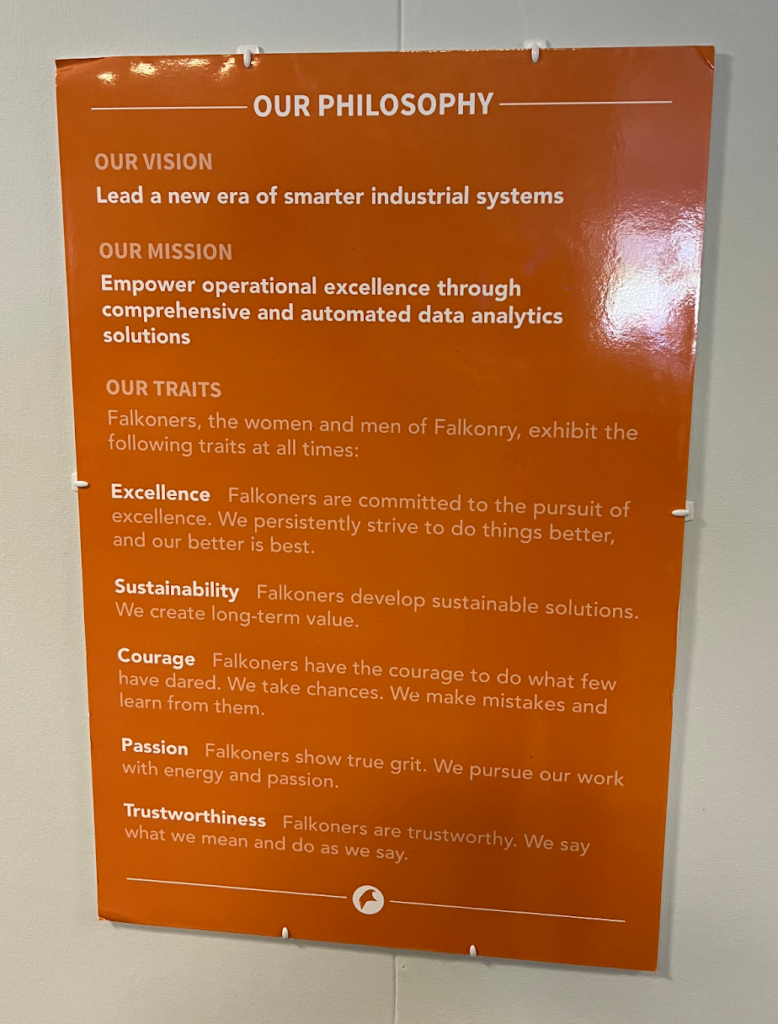

- Falkonry was founded with the mission to make manufacturing smarter through comprehensive and automated analytics

- While the opportunity in industrials is immense for analytics software, it is a challenging space for startups

- Driving enterprise applications with AI, in particular asset operations with time series AI, is going to be a major theme of the coming decade

The recent announcement of IFS acquiring Falkonry marks the most significant milestone in our journey thus far. This is a good moment to reflect on our remarkable voyage, filled with exciting moments and extraordinary challenges, breakthroughs and disappointments, and the path that led us to this exciting partnership.

The early vision

In 2012, when I founded Falkonry, I acted on a realization that industrial companies were seeking software applications to enhance operational efficiencies using data. However, the existing, large software providers lacked interest in and, therefore, poorly handled the peculiar type of data in this area – time series. It was quite obvious that this new data type held immense economic value, yet the technology to properly harness it was sorely lacking at the time. At the same time, DataBricks was getting started at Berkeley, first as the open source project, Spark; C3 and Palantir had got off to a decent start; and cloud became the battle between two providers – AWS and Azure. We were at the doorstep of innovation necessary to address time series challenges.

Identifying the gap

This time series data, since it was generated within all kinds of machinery, had extremely high production volumes. A considerable demand-supply gap existed for support in exploiting industrial automation and sensor data. Another crucial realization was that this data couldn’t be queried or reported like traditional data; it required interpretation for semantic purposes such as pattern, anomaly, or similarity. At that time, this was uncharted territory, and existing research in the field was not ready to be scaled up.

There were, of course, a handful of Silicon Valley companies making some headway in time series analytics for data generated by other software applications. There was an immediate need for software that would make the needs of industrial companies their priority.

Differentiating Falkonry

Soon after Falkonry started, a few startups focused on time series analysis targeting industrial users. One approach involved visual-like searches for characteristic curves in key parameters. This was suitable for regulated industries or those with well-understood curves wherein the notion of a golden batch existed. The second approach leveraged open source libraries to create data science tools designed for data scientists with extensions for time series data mostly focused on forecasting. The third approach combined domain expertise and hybrid models (ML & first principle physics-based) but was limited by the need for extensive proprietary data to seed the models.

We decided not to follow these paths for a few reasons. Firstly, we lacked deep domain expertise in any single industry. Secondly, we realized that time series data was complex even for data scientists, who themselves couldn’t make much progress without extensive help from end users. Some approaches had inherent scalability limitations because of the number of people involved in making them work. There was a clear and large unmet need for an analytics solution that would be suitable for adoption by operations teams to find and explain patterns.

Evolution and Refocusing

Our journey involved several moments of refocusing rather than pivoting. First, we narrowed our focus to cater to the expectations of operations teams, making sure our solutions were user-friendly for those without extensive data science expertise. This was driven by the realization that there were not as many customers who were interested in using pattern identification, which was typically thought of as the realm of data science.

We recognized that the real action was in operations and not in the lab or the corporate office. So, we decided to move away from offline studies. Instead, we chose to go deeper into the world of real time operations i.e. closer to the operations teams. Staying focused on the challenging problem at hand has proven to be a strength for us. While others might have chosen to pivot, we recognized that this problem was truly worth solving.

The road to Anomaly Detection

Our customers played a significant role in shaping our direction, particularly the US Navy. They were interested in a certain type of electrical behavior which didn’t have many occurrences or examples. Hence, to Falkonry it was an unknown behavior from a pattern perspective.

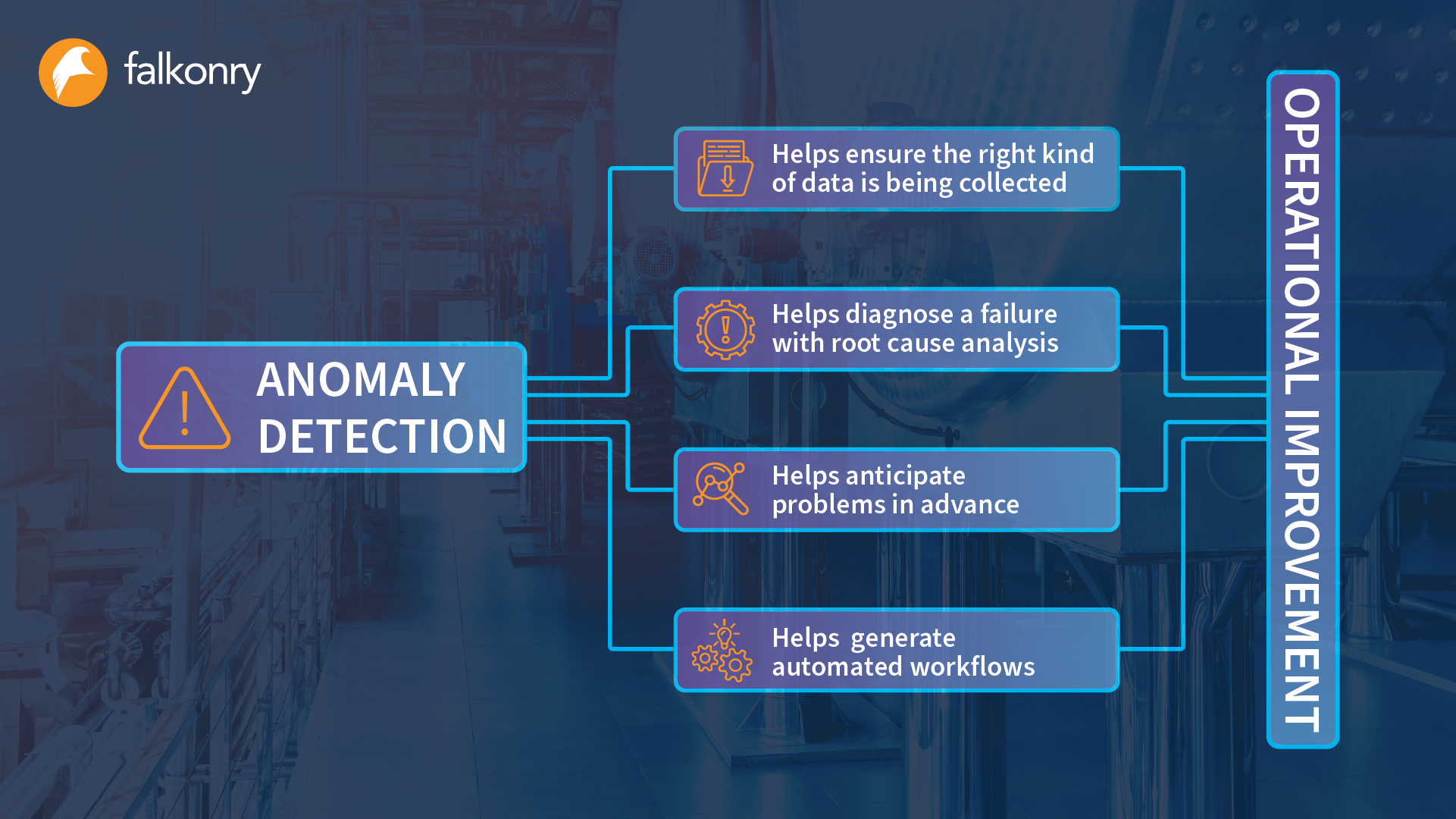

We also saw that our customers would often have to scour a lot of history to get us enough data to build a high-quality classifier. In the absence of such a classifier, an alternate route to getting insights was identifying unusual, new, and novel behaviors or unknown behaviors; in other words anomaly detection. As a result, we prioritized scalable anomaly detection over more user-friendly pattern identification, by designing a deep learning system that not only reduced the computational effort required, but also removed the upfront setup effort and, in the process, enabled much higher scale than is possible through pattern identification.

Overcoming challenges

One of my biggest worries as a founder has been making sure we’re growing fast enough to have the opportunity to fix mistakes. While this is not a problem in most successful startups, in a slow-moving market learning from our mistakes quickly was a challenge. The pandemic, however, changed the landscape, highlighting the critical importance of smart manufacturing.

Looking forward with IFS

As we set our sights on the future, Falkonry’s mission remains unwavering – to make smart manufacturing easy. Our journey has been marked by challenges and triumphs, and this synergy with IFS is a shot in the arm that will take that mission to new heights. Together with IFS, we aim to revolutionize operational optimization, offering an end-to-end solution encompassing asset performance management, manufacturing execution systems, and configurable workflows.

Our immediate focus is to make anomaly detection work seamlessly in various scenarios, from slow to fast data, ensuring that operational teams can act on the insights. We’re working on engineering optimization, scale, performance, reliability, miniaturization, and user interaction enhancements, which broadly means going from anomalies to smart alarms without overwhelming the user.

Exciting times

The technological strides of the past decade have unlocked the power to extract actionable events from industrial automation data at an affordable cost, leading to nearly 20 issued patents for Falkonry. This perfectly aligns with IFS’s core attributes – scalability and low-cost implementation.

Our shared vision extends beyond software – it goes deeper by tapping into the immense potential of asset-intensive industries and operational management. The systematic deployment of anomaly detection and time series AI in these sectors promises to create unprecedented value.

Exciting times lie ahead and I’m looking forward to seeing what we can achieve together. We hope to continue sharing our learnings along the way as so many of you have followed our progress and findings all these years. For now, I will leave you with Falkonry leadership team’s perspectives on joining the rapidly-growing IFS ecosystem.

What the Falkonry leadership thinks

Dan Kearns, CTO: People have talked about how “data is an asset” for years, but in many places there has been no maturation in the maintenance and operation of those assets. Bitrot is real, and “data fouling” is a term that I hope catches on. If you’re just storing data and not actively using and maintaining it, more than likely it’s already broken. The strategy you’ve adopted is called “run to failure” and, while it has its place, the only option available at failure is replacement. IFS reminds me of Guidewire in that they have a pretty amazing relationship with their customers. One of my favorite CEO quotes is from Guidewire’s Marcus Ryu. Paraphrasing, “enterprise software is like tunneling through granite,” the idea being that if you’re not attempting something difficult then you aren’t serving your customers well. We’ve done some of that digging, but taking a step back from algorithms and rethinking well-established processes in the asset-people-customer space through the lens of data, AI, and “servitization” is something we wouldn’t be able to do without the depth of the IFS team, and the host of intrepid customers patiently helping us figure it out.

Dan Kearns, CTO: People have talked about how “data is an asset” for years, but in many places there has been no maturation in the maintenance and operation of those assets. Bitrot is real, and “data fouling” is a term that I hope catches on. If you’re just storing data and not actively using and maintaining it, more than likely it’s already broken. The strategy you’ve adopted is called “run to failure” and, while it has its place, the only option available at failure is replacement. IFS reminds me of Guidewire in that they have a pretty amazing relationship with their customers. One of my favorite CEO quotes is from Guidewire’s Marcus Ryu. Paraphrasing, “enterprise software is like tunneling through granite,” the idea being that if you’re not attempting something difficult then you aren’t serving your customers well. We’ve done some of that digging, but taking a step back from algorithms and rethinking well-established processes in the asset-people-customer space through the lens of data, AI, and “servitization” is something we wouldn’t be able to do without the depth of the IFS team, and the host of intrepid customers patiently helping us figure it out.

Kevin D Clark, VP, Time Series AI and Customer Success : It’s not often you get to watch such an amazing transformation, growing, developing, growing again, developing, developing, developing, and then finally to be recognized by the industry as a leader. Congrats to Falkonry and IFS as we start this new journey.

Ashis Khan, VP, Smart Manufacturing: Falkonry and IFS share a common vision for the future of Moments of Service, and I am excited to see what we can achieve together. Falkonry’s AI Copilot delivers AI-powered Moments of Service as Actionable Anomaly Alerts to manufacturers and energy producers. High-severity Anomaly Alerts help them avoid delays, unplanned stoppages, and slowdowns, thereby improving productivity and sustainability and increasing EBITDA and ESG scores. By joining forces with IFS, which has 6,500 satisfied customers, we are all set for explosive business growth.

Ashis Khan, VP, Smart Manufacturing: Falkonry and IFS share a common vision for the future of Moments of Service, and I am excited to see what we can achieve together. Falkonry’s AI Copilot delivers AI-powered Moments of Service as Actionable Anomaly Alerts to manufacturers and energy producers. High-severity Anomaly Alerts help them avoid delays, unplanned stoppages, and slowdowns, thereby improving productivity and sustainability and increasing EBITDA and ESG scores. By joining forces with IFS, which has 6,500 satisfied customers, we are all set for explosive business growth.

Sheetal Birla, GM, Europe and Asia: Combining our unique strengths bolsters our mission of enabling smarter factories and smarter decisions, in industries across the world. We have achieved breakthroughs in Time Series AI — to solve real, complex, large problems in manufacturing and defense at a scale no other approach has been able to. Together with IFS, we can bring a whole new level of AI-powered workflows and Moments of Service for our customers and partners.

Sheetal Birla, GM, Europe and Asia: Combining our unique strengths bolsters our mission of enabling smarter factories and smarter decisions, in industries across the world. We have achieved breakthroughs in Time Series AI — to solve real, complex, large problems in manufacturing and defense at a scale no other approach has been able to. Together with IFS, we can bring a whole new level of AI-powered workflows and Moments of Service for our customers and partners.