Rapid, Flexible Analysis with Falkonry time series AI

Key takeaways:

- How a system is defined determines how readily patterns of interest can be found, but figuring out the best system definition which highlights important behaviors is hard

- Time series AI shows a path to resolving this difficulty by making iteration simple

How you look at something determines what you see.

The world of optical illusions provides a variety of entertaining and sometimes perplexing examples. The world of equipment modeling is similar. In complex systems, behaviors of interest arise from interactions between components. So the patterns that can be found in the operational data will depend very much on the components being observed. However, even with subject matter expertise, it isn’t always obvious what the “best” combination of components is or if any one particular combination is “best”. This is especially true when work is just starting or the behaviors of interest are uncharacterized. What to include? What to exclude? In what combination?

While there are some analytic techniques that those well versed in data engineering could apply, this isn’t an option for the operational team whose expertise lies in process or equipment operation. One of the primary learnings that led to the development of our time series AI platform is that making machine learning easy enough for non-data science experts can mean doing things in a different way. In this case, it means relying on iteration rather than closed-form analysis. For that to work, we had to make defining a range of different system configurations easy.

A system configuration, in a modeling sense, comes down to deciding how to describe the equipment or process. In traditional ML, this means feature engineering: How do I want to describe the system in terms of the sensor data available? Generally speaking, this is an unsolved problem and requires significant data science expertise to do well. This puts it outside the scope of what an operations team can be expected to do on their own. Our time series AI takes a different, more intuitive approach.

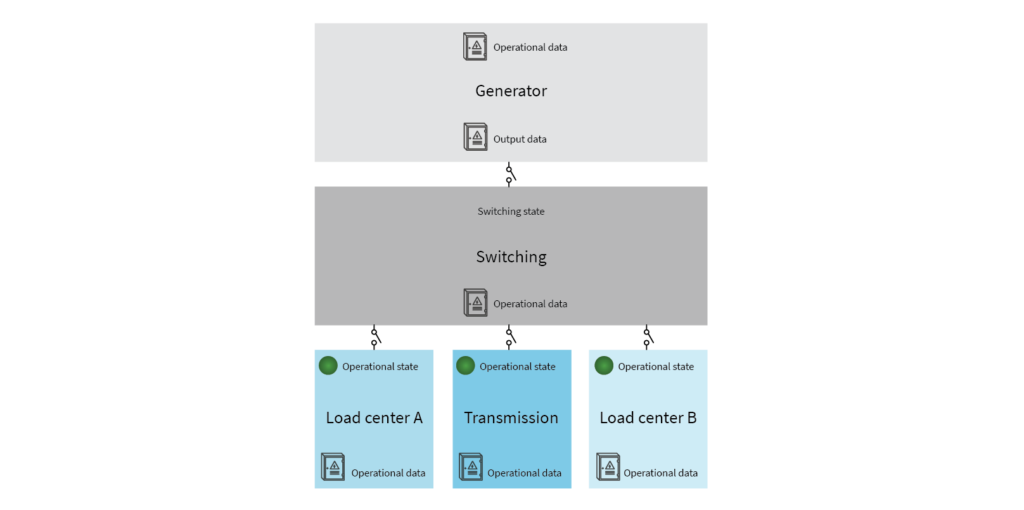

For example, take a system that generates power (Generator), routes it (Switching) to a number of load centers (Load Center A and Load Center B) and can transmit to more distant consumers (Transmission) as shown schematically below.

What is the “right” way to model this system?

Do I model each component (i.e. the generator, switching gear, load center A, load center B and transmission equipment) separately?

Maybe. Do I model them all together? Maybe. Do I take some combination (e.g. generator and load center A) and model just those parts? Maybe.

It all depends on what the behavior of interest is. There may be a generator lube seal that wears out frequently. Looking for that kind of part failure might be best done by isolating the generator. Or maybe there is a switchgear breaker trip that might be due to some specific combination of loads. In that case the “right” modeling approach includes the switchgear, load center A and load center B. Sometimes, the behavior of interest is not well understood and iteration through a number of different combinations of components is necessary. There isn’t a single answer.

Because of complexities like this, it is important for the operations team to be able to change system definitions without the help of a data science team if that team is to leverage their domain knowledge and scale models to all the areas they are responsible for.

Falkonry makes this definition process easy. Our time series AI platform has the ability to define equipment or components in terms of signals by selecting related signals and assigning them to equipment with a few clicks. This method is flexible but designed to be easy enough for the Subject Matter Experts (SMEs) to use on their own.

Want to try separate models per component? Check.

Want to group components together? Check.

Want a different configuration in the model? Check.

By taking care of the hard parts of data preparation in the background, our time series AI platform makes it intuitive for SMEs to leverage their expertise and experiment rapidly, even for complex systems. This gets them to better answers more quickly in a way that preserves that knowledge for the long term.