Enable Condition-Based Actions with Flexible Rules

Key takeaways:

- Rules bridges the gap between data analysis and real-world impact by generating smart alerts that trigger condition-based actions in downstream systems.

- It is an effective mechanism to inject expert opinion and control into AI, ensuring that analysis outputs are selectively emitted for human action when necessary

- Rules provides a way to succinctly express domain knowledge and compare it to automated AI analysis, enabling users to build trust and increase AI adoption

In industrial operations, one of the most common challenges has been translating data and analytics insights into actionable value. Despite the abundance of data from sensors and the continuous improvement in IIoT connectivity, bridging the gap between analysis and impactful action has remained difficult. In response to this challenge, Falkonry has developed a solution designed to streamline the creation and implementation of alerts on industrial data at scale, enabling condition-based actions to be executed by anyone on “anything” within the plant.

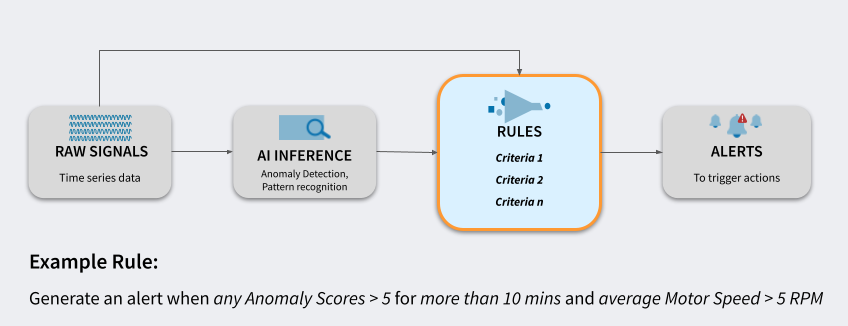

Since its inception, Falkonry has dedicated its efforts to simplifying industrial analytics and advancing smart manufacturing. Initially, the focus was on Machine Learning approaches that relied on subject matter experts to guide the learning process. However, the subjective and error-prone nature of this supervision posed a challenge. To overcome this, we developed automated anomaly detection, leveraging self-supervised micromodels to identify unusual behaviors. This led to the creation of our deep neural network (DNN) based advanced anomaly detection capability, which enabled large-scale automated plant monitoring. However, we recognized that merely monitoring operations is insufficient. It was crucial to infuse expert opinion into the automated models and establish guardrails ensuring that model output is selectively emitted for human action when necessary. Thus, a flexible rules-based system was developed to alert operations personnel when certain conditions are met.

What Do Rules Address?

Rules act as a safeguard: It is designed to prevent unnecessary alerts from being triggered by transient behaviors, ensuring that alerts are only raised when there is a sufficient persistence of an issue. By distinguishing between persistent and transient anomalies, rules act as a safeguard, preventing users from being overwhelmed by a flood of alerts.

Rules ease AI adoption: Many operations teams find the transition to AI challenging due to the effort required to understand AI-generated results. The rules provide a solution by allowing users to compare their domain-specific knowledge to insights surfaced by AI. This approach of comparing AI results with the outputs of rules developed by domain experts helps develop a greater understanding of what the AI is doing and how it can gradually supplement domain expertise over time. This comparison not only builds confidence in AI but also serves as an effective on-ramp to AI adoption.

Rules deliver on the unfulfilled promise of Condition-based Maintenance (CBM): This goal has long been elusive due to the difficulty in programming and maintaining condition-based rules across the enterprise. Falkonry AI’s capacity to identify timely insights represents a more advanced approach to condition monitoring. However, both rule-based condition monitoring and AI-based condition monitoring eventually have the same goal – which is to suggest actions that are appropriate for the given conditions.

How do Rules work?

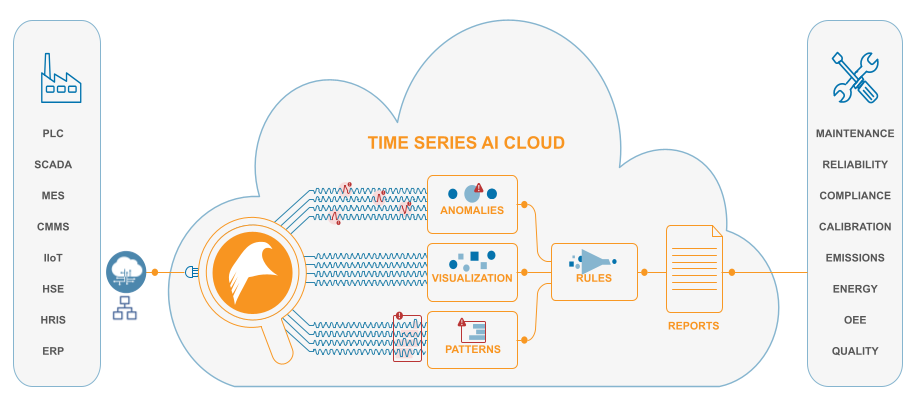

Rules are an integral component of the Falkonry Time Series AI architecture, which promises to optimize business operations across various industrial domains. This solution operates by analyzing industrial data for thresholds, anomalies, or patterns and subsequently routing the output to other workflows for action execution. What distinguishes Falkonry’s rules capability is its ability to denoise and filter patterns and anomaly outputs, or consolidate rule outputs before triggering alerts. Essentially, rules serve as a versatile no-code programming environment for end-users, offering limitless expression possibilities.

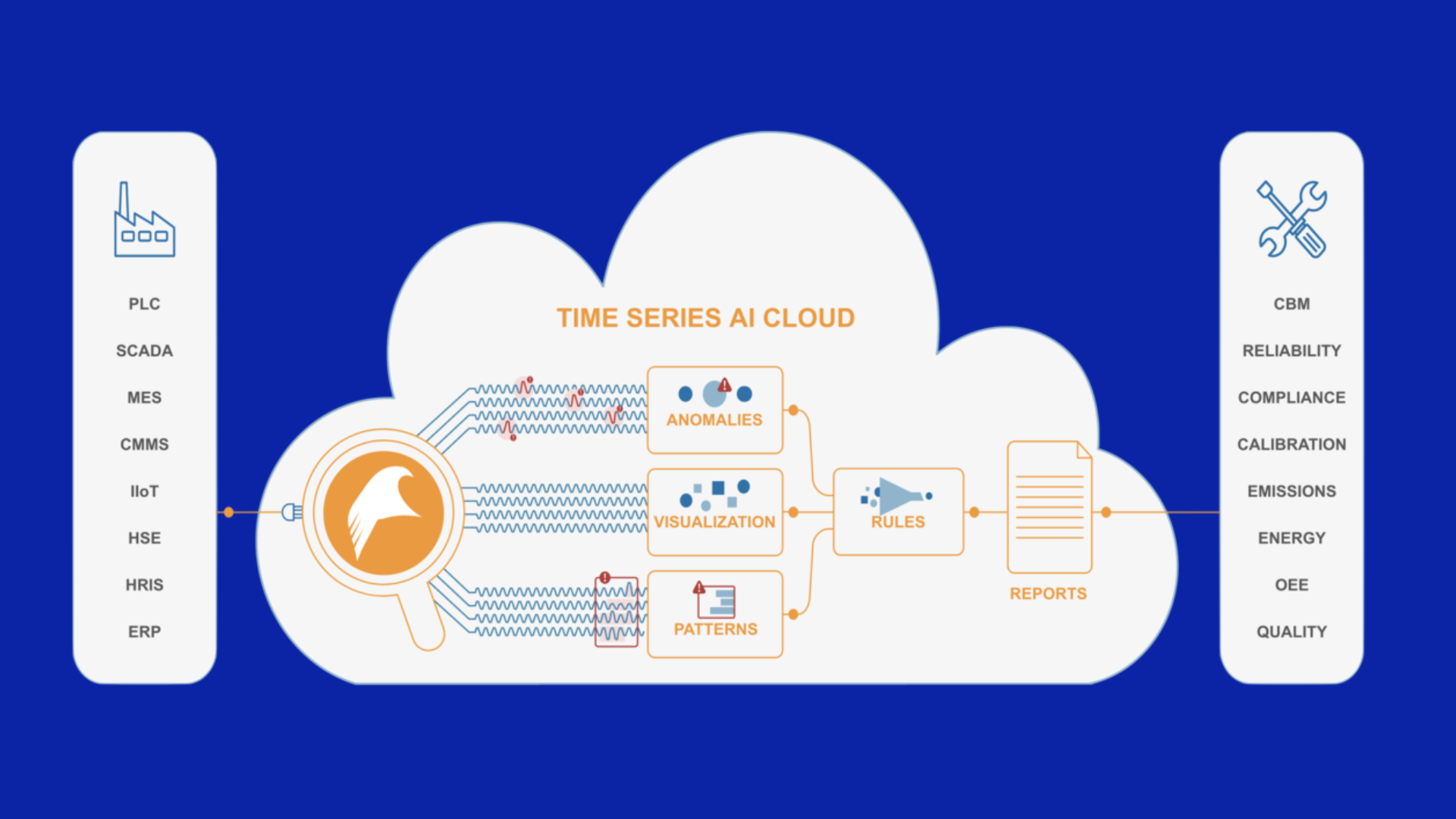

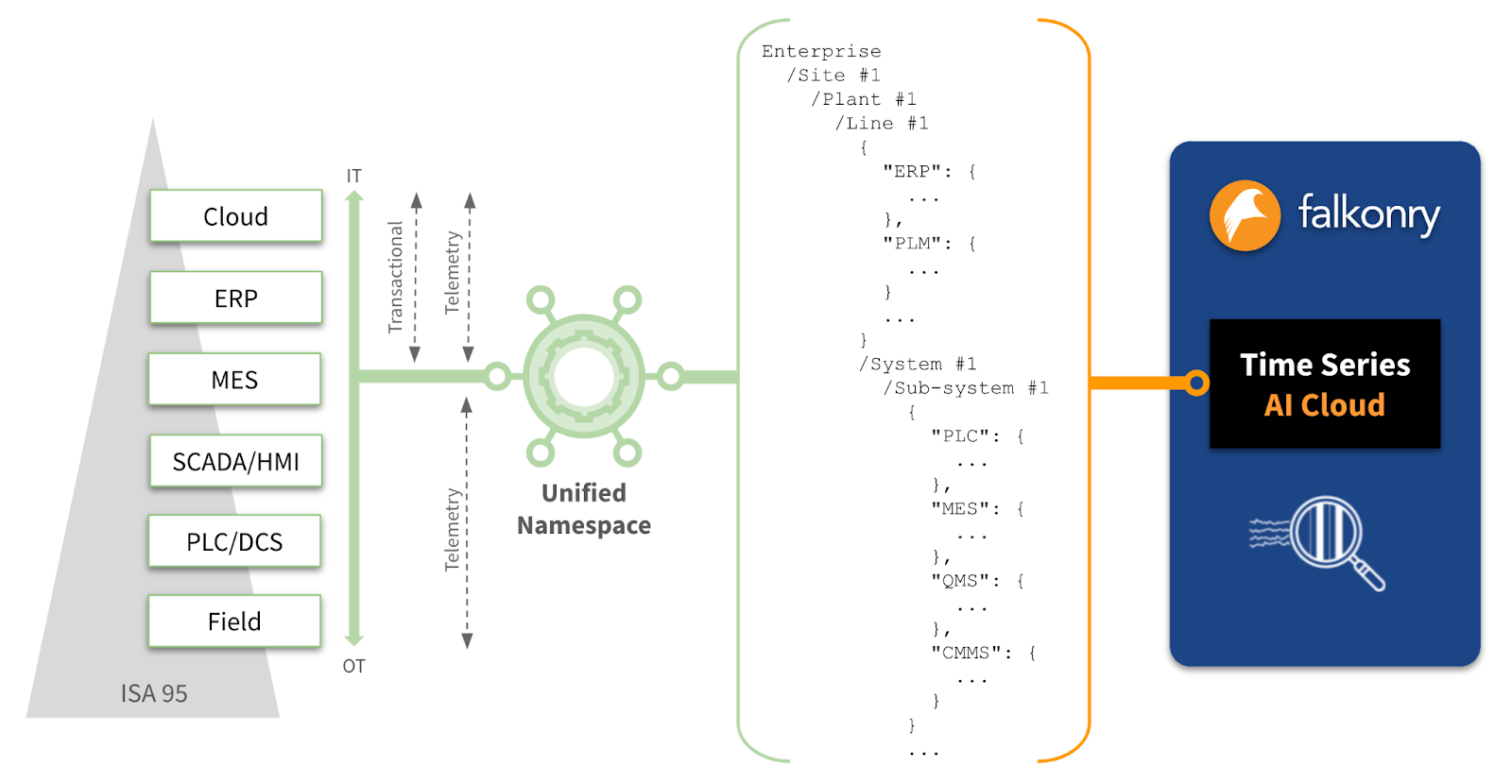

Time Series AI Cloud is specialized for streaming time series analytics

Rules can be applied to diverse operational data sources, including machine and process data from PLCs and sensors, manufacturing schedules from MES, maintenance data from CMMS, and vibration data from vibration sensors. Moreover, it can seamlessly integrate with data processed by Falkonry’s AI analysis tools. By continuously assessing one or more signals against predefined criteria, we can now generate smart alerts that trigger actions in downstream systems.

Ease of Configuration:

Setting up the rules in Falkonry is a breeze. While configuring alarms in traditional PLCs and SCADA systems can be cumbersome, our intuitive interface coupled with real-time data visualization during the setup phase simplifies the process, ensuring that anyone, regardless of their technical expertise, can configure rules. This intuitive approach streamlines the configuration process, enabling users to set up rules quickly and efficiently.

Adaptive Capability:

Rules exhibit remarkable adaptability in handling ambiguity and imprecision across sensor groups. For instance, rather than configuring individual rules for each sensor in an array, users can set up a single rule to monitor multiple sensors, significantly reducing the configuration overhead and alert fatigue.

Customizing rules to drive condition-based actions

Driving Proactive Action:

Beyond simply flagging anomalies, rules empower users to take proactive action by getting alerted of the critical deviations from expected or normal operating behaviors. This lets you stay ahead of the curve and minimize downtime before it even occurs.

In conclusion, Falkonry provides a comprehensive solution for both seasoned CBM professionals and early adopters seeking to simplify smart manufacturing. With our innovative approach to rule-based condition monitoring, we offer a recipe for effectively bridging the gap between data insights and actionable value. If you’re interested in exploring how rules can transform your operations, watch our smart alerts webinar to learn more and sign up for a trial today.