AI-based operational excellence in steel manufacturing

Key takeaways:

- At least one day per month of production time is lost to machine failures, costing industrial manufacturers including steelmakers $50 billion annually.

- Such instances of machine failures or quality deviations in production stem from the operational blindspots that exist in plant operations.

- Time-series AI can help detect and explain these blindspots in real-time, providing operations and maintenance teams with actionable insights to address events before they adversely impact operations

Steel casting and milling are complex processes involving extreme physical stresses at considerable temperatures. The equipment that performs these tasks require large investments to procure, install, operate and maintain. Hence, maximizing revenue generation from existing capital assets is essential for the modern steel mill to remain competitive. The use of AI in steel manufacturing is unlocking unparalleled opportunities in achieving newer heights of operational efficiency and reliability, thereby allowing steel companies to maximize production uptime and maintain quality.

The automation of the equipment and processes happening over the past couple of decades has given way to the accelerated adoption of Industry 4.0 and IIoT-based initiatives that focus on sensors and connectivity. Operational data is being collected at a velocity and volume like never before. Insights are no longer limited to human inspection and domain knowledge but are now acquired using digital technologies and advanced analytics practices.

Application of AI unearths multiple new goals of operational excellence. The primary role of AI is to provide complete visibility of every action of every machine and process. Second, find patterns in the data and provide explanations, ie, discover where the problem is and what to do about it. As a result, predictive maintenance and quality monitoring procedures directly benefit from AI and lead to increased equipment availability, production uptime, and throughput.

Finally − and most importantly – they enable continuous improvement not only in existing processes and work practices, but also in enhancing feedback into engineering, product design, and sustainability projects.

Current challenges and role of advanced analytics

Modern steelmaking is heavily instrumented with several process parameters being monitored, yet there are limited operational insights available in real-time. Take, for instance, the continuous casting process − a facility producing 150 tonnes per hour can generate over US$5 million per day in production revenue, assuming current steel prices. Conversely, a single day of lost production is equivalent to US$5 million worth of losses. Therefore, a manufacturer can unlock tremendous value by eliminating these unscheduled production downtimes.

Casting molten steel, unsurprisingly, is hard on heavy equipment. Components wear under harsh conditions leading to failures or adverse product quality. Early detection of such conditions could warn the maintenance and production managers to schedule repairs before failures occur. Applying advanced analytics to machine and process data can help in predicting such unwanted events. Data-science projects are often designed for specific use cases thereby limiting the scope and interoperability of the model. The approach faces challenges in terms of model sustenance in production and scalability across use-cases or plants. This could be attributed to several factors:

1. Using historical data to build future models A dynamic production environment, where operational states change rapidly, ensures that failures are not precisely repeatable. Equipment and processes evolve and old models don’t detect new failures; in fact, they might see new normals as false positives. This leads to what is known as the model-churn phenomenon wherein the training and validation of models requires so much time that any completed data model is obsolete as it nears deployment.

2. Apply AI to only a limited number of use cases Many steel manufacturers are still in the proof of concept and pilot purgatory stages, with an intention to create high-reliability prediction systems within a defined use case in order to prove ROI. The difficulty with this approach is that getting to the point of high prediction reliability tends to take a long time. During this time, any systemic changes (part replacements, process changes, etc) would make the resultant AI-based solution quickly irrelevant. Our experience with AI, and particularly when it comes to scaling, reveals that adequate benefits from AI accrue not from the depth of application but from broad application across a large number of applications.

3. Limited buy-in from the ops team: When a technology solution is implemented from the top down, there is a natural resistance to change which hampers adoption. For an AI system to be self-adopted by on-ground practitioners, it has to be easy to use and its usefulness should be evident from the outset. When an AI system is able to ingest and analyze real-time data to surface insights quickly, operations personnel find value in it and advocate the scalability.

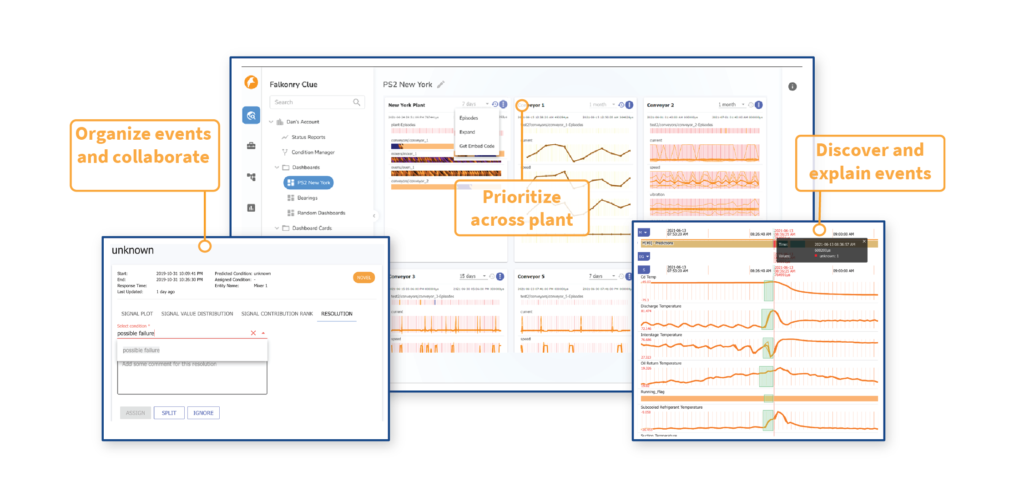

Hence, there is a strong demand for advanced analytics to provide real-time operational insights that are not only actionable, but also explainable and easy to use. In our experience, the discovery of patterns or anomalous conditions is only a part of the puzzle. The most value comes from the explanations of those patterns – answering why at a particular point in time a particular asset or system is identified as needing attention. Automated discovery and explanations of production events help the maintenance and reliability teams to find ‘what’ the problems are; ‘where’ they are happening right when they are happening; and ‘why’ the event is happening with the details of contributing factors. This helps the maintenance team use their operational know-how to prioritize actions across the assets, lines or the entire plant. One of the key characteristics of the Falkonry AI and ML platform is that it provides explanations for the conditions that it discovers and detects.

AI in steel manufacturing

Falkonry’s time series AI software platform enhances operational excellence by avoiding operational events that disrupt manufacturing and production operations. As such a broad set of problems need to be solved for increasing operational excellence. These include reducing downtime, increasing throughput, enhancing capacity utilization, increasing yield, reducing and eliminating defects, and lowering changeover time. For such operational excellence solutions, the AI needs to offer a broad set of process and asset-agnostic capabilities. Time series AI functions by applying machine learning to operational data to discover and report behaviors that engage operational experts and solicit their know-how through accessible interfaces. It is easy-to-use, meaning that front-line subject matter experts such as maintenance and reliability engineers, process engineers, maintenance managers, and those with similar experience, can use it themselves. Such AI produces applications that predict undesirable system behavior and can be evolved without assistance from data engineers or data scientists. Hence results are achieved more rapidly, the solution scales more quickly, and at a lower cost than traditional analytics.

From our experience working with leading international steel manufacturers, these are the capabilities of time series AI that have enabled scaled outcomes in production:

- Instant insights surfaced from the automated and continuous discovery of production events in real-time

- Explanations help understand why the event is happening with details of all the contributing factors and develops trust in the AI system

- Capturing the human tacit knowledge enables collaboration across the operational teams and prioritizes actionables across the plant

- Plant-level operational visibility provides granular reporting and workflow adoption and helps precisely understand the antecedents and consequences of events

- Flexible deployment be it on cloud, edge, on premise or air gapped; the same solution is available from everywhere.

Application on the field

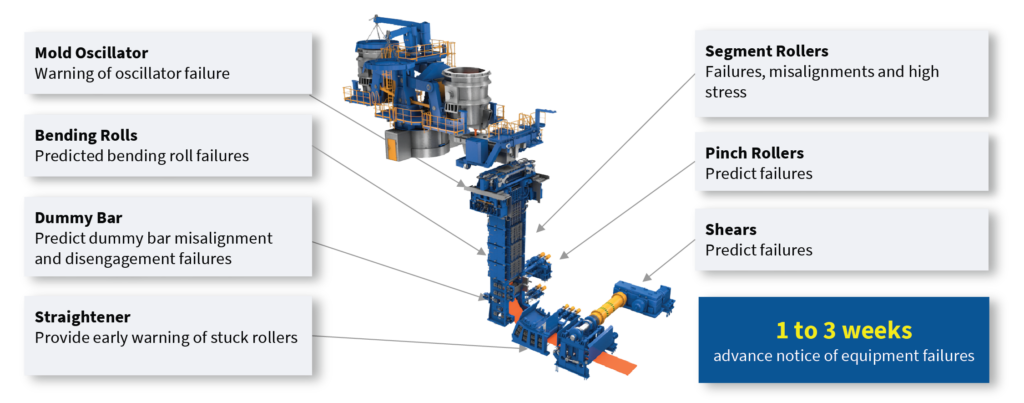

Time series AI can be applied across the steelmaking processes from casting to finishing lines. Various components of casting operations from the molds and pinch rollers to the bending roll can be monitored for predicting and detecting early degradations in critical components. Fig 1 illustrates the continuous monitoring of all the components of a vertical caster.

By feeding the signals from all the components into the time series AI system, we get a unified real-time view of the dynamic operating modes of various components. The input signals involve multimodal data consisting of quantitative signals such as current, torque, motor speed, hydraulic pressure, etc and categorical signals such as value status, alarm codes and so on. Automated unsupervised machine learning identifies essential patterns of behavior that give the operational experts a better idea of different operating modes. The anomalous events such as part failure, misalignments, or high force events are marked as warning periods and the system then performs semi-supervised learning to create models that can discover and distinguish between patterns across supplied parameters.

The ML application, now having learned to detect and recognize the relevant operations patterns occurring before conditions of interest, can be used to predict the undesirable events of interest from the real-time data stream. This intelligence-first approach readily scales up across assets, processes and plants and provides the operations team with explanations along with contributing factors, in-the-moment guidance (decision-support) and superior operational visibility.

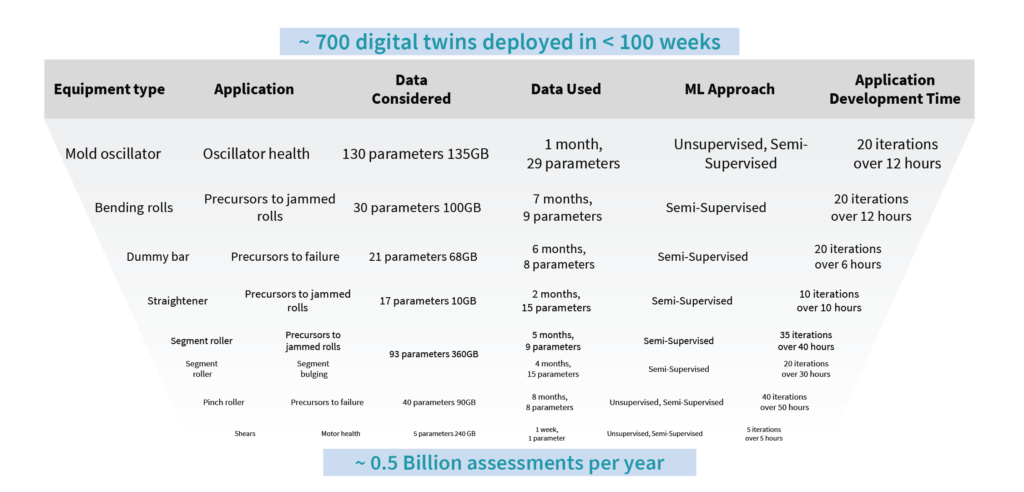

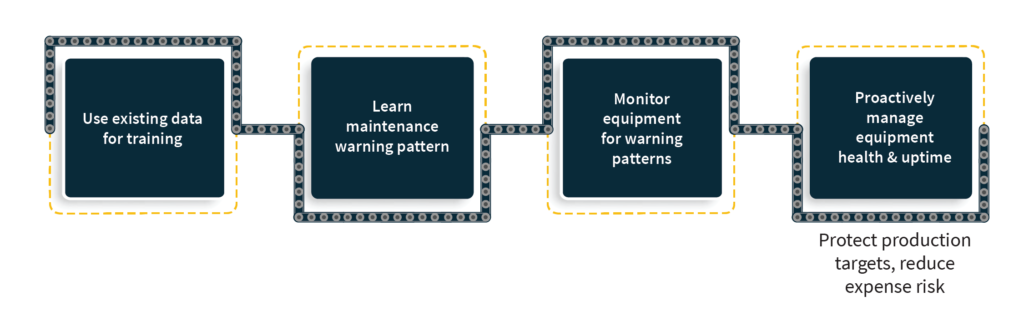

Fig 2 puts this into perspective: Over 700 asset twins are monitored for a range of use cases by analyzing around half a billion assessments. By leveraging a combination of unsupervised and semi-supervised learning, the models are developed and validated rapidly despite such large variety and volume of data. The ability to automatically understand the contributing parameters accelerates the troubleshooting and corrective action determination for the predicted failure conditions. Fig 3 illustrates the flow of the AI-based predictive maintenance solution.

There are also opportunities for detecting quality defects in cooling tables, strip break classification and laser cutters. To illustrate how time series AI can generate value, let’s look at one particular use case – cooling tables. In the casting process, the steel slab that comes out goes on to rollers, which number in their hundreds and are driven by motors. A key challenge here is that as the motor, the coupling, the gears and the roller surface itself degrade, they start to drag on the surface of the steel, causing defects in the steel surface. So the quality is an outcome of the need for maintenance.

With the help of time series AI, the earliest possible indication of a poorly performing roller could be detected. The maintenance team could get explanations from the captured information and drill down to know that the faulty drive motor, for instance, needs corrective action. Another case involves strip breaks. One of the biggest challenges in this application is not identifying whether the strip break has happened, but whether the potential causes of that strip break can be identified. Time series AI can characterize all of the associated equipment to identify potential causes of any series of strip breaks, and then use that information to correct the process.

Conclusion

For the AI to scale up and succeed in the steel mills, it is important to think beyond the use cases and cast a plant-wide net to discover and detect anomalous behaviors in the equipment and the processes. This allows the operations team to have a unified view of the operational excellence goals spanning across reliability, quality and process efficiency. By putting AI directly in the hands of the operational experts, the insights are developed and validated at a faster rate, which is a prerequisite for the scaled implementation of AI in production (Fig 4). Most importantly, this ensures that the AI adapts seamlessly to the changing business and operating conditions, building trust and buy-in from the operations team. With scaled adoption of time series AI, leading steelmakers expect to achieve up to 50% year-over-year reductions in unplanned downtime.

Falkonry has invested millions of dollars to build an AI platform that unlocks the above-mentioned opportunities in digital operations. With over eight years of research and development and over a dozen issued and pending patents, Falkonry is committed to making industrial AI accessible, trustable and accountable to the frontline operations team in steel manufacturing, so that companies can set new standards of achieving AI-enabled operational excellence.

A version of this blog was first published by Steel Times International on Nov 16 2021