Post COVID-19: Strategies beyond the restart

The global spread of the novel coronavirus has impacted nearly every industry in one way or the other. While the current headlines focus on business uncertainty, sudden surge in certain manufacturing demand, disruptions in production and broken supply chains, we believe manufacturing companies will also face great challenges in continuity management due to skill gaps exacerbated by shelter in place and social distancing protocols.

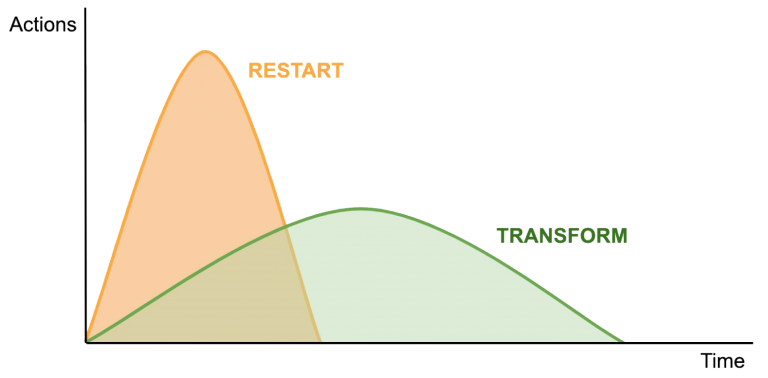

Our work with industrial digital transformation customers has highlighted challenges with knowledge transfer that existed well before COVID-19. While we are all trying to get through today’s challenges, new ways of thinking are being tested and a window of opportunity for major change has emerged. Post COVID strategies should focus not only on restarting operations, but also on paving the way for a longer term transformation towards more resilient manufacturing operations.

Falkonry can help organizations respond to the unprecedented disruption caused by COVID-19 and navigate from recovery to the “new normal”. Below we have listed a few ways in which Operational AI can combine operational excellence and business continuity to help drive productivity during and after the recovery effort.

Fig 1 – As intensive, short term actions are taken to restart business, your post COVID strategies should consider the less urgent but possibly more important, long term actions needed to transform your business into a resilient organization: One better able to cope with future shocks

RESTART

Ensuring employee health and safety will be the most important priority as manufacturers start resuming operations. This will lead to new measures for staffing including staggered shift times, remote work, reduced hours and physical distancing. As per Gartner, 40%-50% of the workforce will be unavailable to perform their functions onsite. Falkonry can help manage this challenge by delivering production insights which local and remote factory employees can both use to work more effectively.

Some companies had to temporarily shutter factories in response to government restrictions or falling demand. As the lockdown eases, these factories and machines will need to be restarted. Falkonry’s solution for predictive operational excellence can provide early warning of unexpected asset behavior – particularly helpful in identifying production restart oscillations and other rest-restart-induced issues.

As businesses continue the return to “normal”, the focus of post COVID strategies will shift to mid-term cost improvements and increasing flexibility to manage an uncertain future. According to a survey conducted by the National Association of Manufacturers (NAM), more than 78% of manufacturers anticipate a (negative) financial impact on their businesses. In addition, over 53% anticipate a change in their operations due to reduced demand, curtailed travel, and restricted interactions.

To help manage these increased risks, Falkonry’s operational AI provides automated, remote, continuous insight into critical system behavior. This real-time visibility over production efficiency and quality allows plant personnel to identify issues before they impact business or respond more quickly to a disruption that does occur. Finding and addressing these behaviors early can speed time to profitability by reducing loss of production, scrap and material waste as well as maintenance costs.

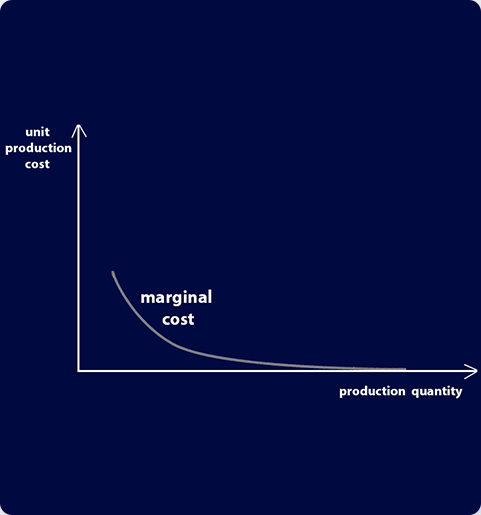

Operational AI provides production operations teams a low cost way to increase production efficiency while reducing the incremental cost per problem to near-zero.

TRANSFORM

The Covid-19 crisis will have long-lasting effects on manufacturing organizations, but it also creates an opportunity to rethink the way work is done. Many companies were already adopting new digital technologies and the underlying economics of that effort remain unchanged. Post COVID strategies will highlight the importance of adding resilience to the usual economic and efficiency considerations. People and knowledge are as important as quality control and predictive maintenance practices.

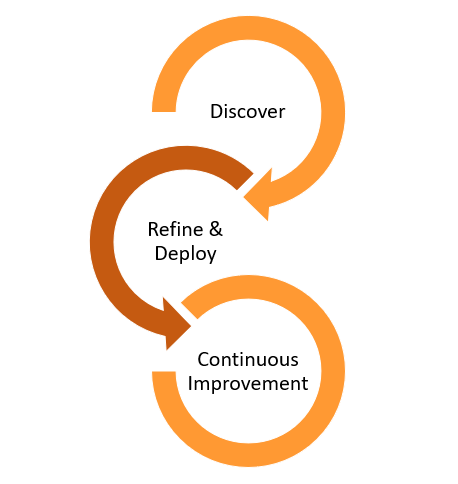

Introducing agility into your operational excellence tool kit can help improve your resilience. Using cycles of fast learning, root cause analysis on discoveries of inefficiency and rapid action, driven by decentralized teams that can act quickly on many potential improvement areas is a key opportunity for growth. Agile, a development philosophy built to accommodate the fast moving nature of software, can apply in heavy, capital intensive industries when used to support these kinds of activities. Learn more how digitalization goes Agile.

Falkonry’s approach to predictive operational excellence supports post COVID strategies like this because it enables an Agile approach. Falkonry pre-packaged operational AI analyzes and acts on today’s operational data, enabling plant personnel to accelerate operational excellence and to systematically capture knowledge of operational experts.

To learn more about how your organization can navigate immediate disruptions and prepare for the future, watch this space or get in touch.